Preparation of textured piezoelectric ceramic using (001) oriented sheet-like SrTiO3 as template material

A piezoelectric ceramic, textured technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve problems such as the performance of single crystals, the difficulty of single crystal growth technology, etc. Achieve the effect of high voltage electric constant and high degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

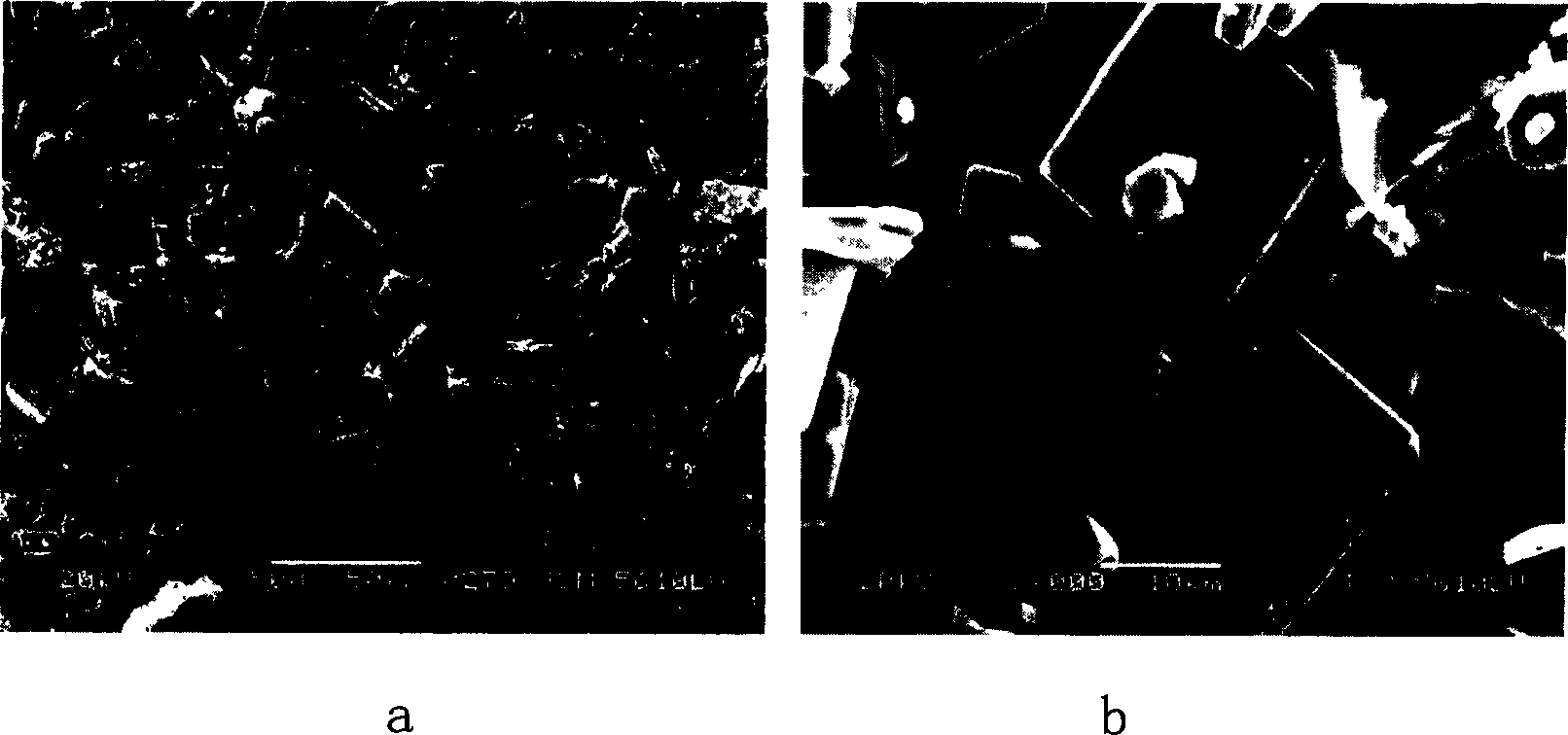

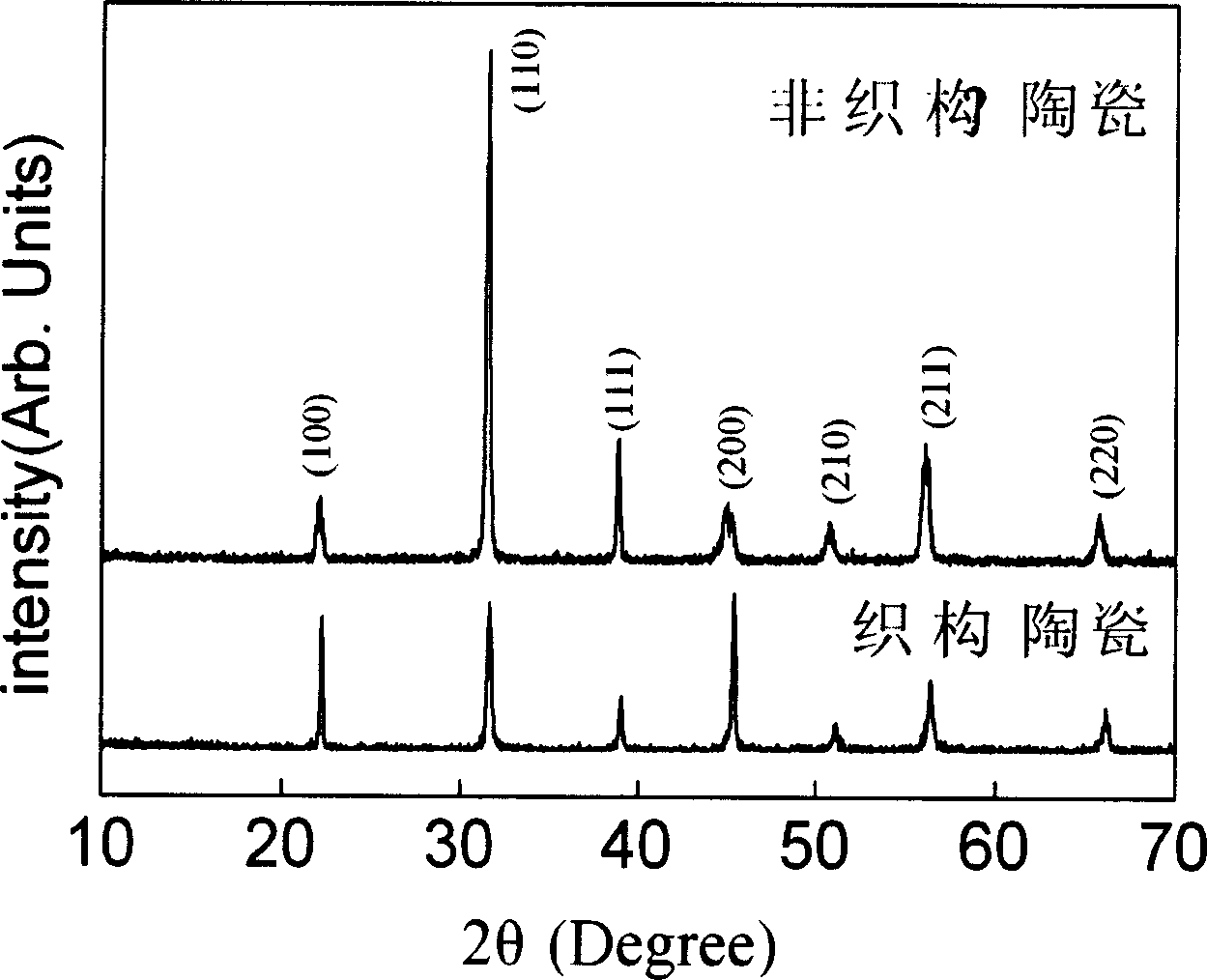

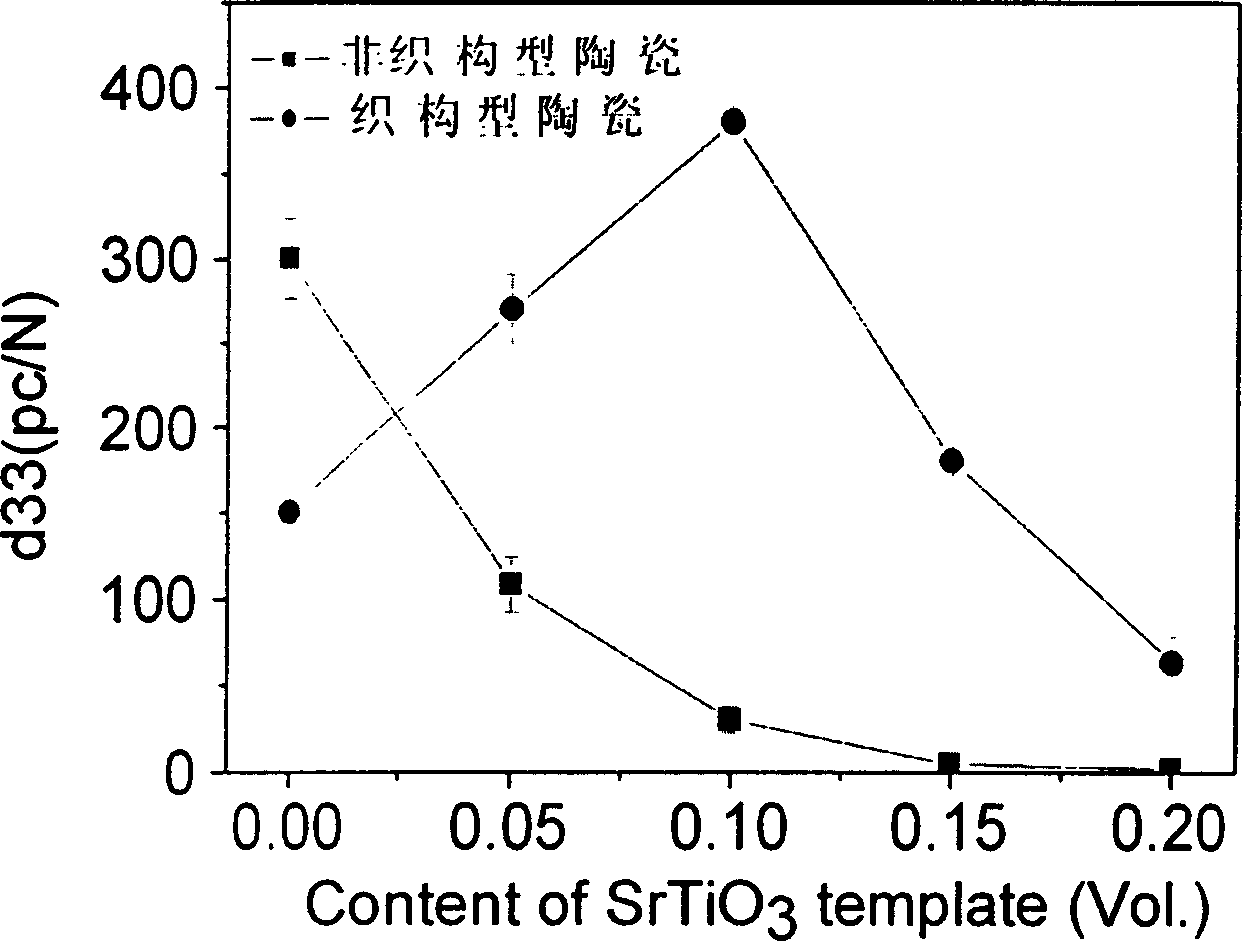

Image

Examples

Embodiment 1

[0026] By Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.429PbTiO 3 +SrTiO 3 =96.54wt%+3.46wt% batching, the mixed solvent that adopts dehydrated alcohol and methyl ethyl ketone volume ratio to be 1: 1 composition, the blending amount of dispersant, binding agent and plasticizer is respectively 1.10 of the total amount of mixed powder wt%, 2.64wt%, 4.65wt%, cold isostatic pressing molding pressure is 300MPa, immersion in 3wt% PVA for 5 hours, secondary pressing molding pressure is 300MPa, hot pressing sintering temperature is 900°C, sintering time is 0.5 hours; air The sintering temperature under the atmosphere is 1150° C., and the sintering time is 4 hours.

Embodiment 2

[0028] By Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.429PbTiO 3 +SrTiO 3 =95.00wt%+5.00wt% batching, the mixed solvent that adopts dehydrated alcohol and methyl ethyl ketone volume ratio to be 2: 1 composition, the blending amount of dispersant, binding agent and plasticizer is respectively 1.20 of the total amount of mixed powder wt%, 2.70wt%, 4.82wt%, the cold isostatic pressing pressure is 400MPa, soaked in 4wt% PVA for 5 hours, the secondary pressure molding pressure is 350MPa, the hot pressing sintering temperature is 950°C, and the sintering time is 0.5 hours; air The sintering temperature under the atmosphere is 1150° C., and the sintering time is 6 hours.

Embodiment 3

[0030] By Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.429PbTiO 3 +SrTiO 3 =93.50wt%+6.50wt% batching, the mixed solvent that adopts dehydrated alcohol and methyl ethyl ketone volume ratio to be 1.5: 1 forms, the blending amount of dispersant, binding agent and plasticizer is respectively 1.15% of the total amount of mixed powder wt%, 2.85wt%, 4.82wt%, the cold isostatic pressing pressure is 400MPa, soaked in 5wt% PVA for 8 hours, the secondary pressure molding pressure is 400MPa, the hot pressing sintering temperature is 1000°C, and the sintering time is 0.5 hours; air The sintering temperature under the atmosphere is 1150° C., and the sintering time is 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com