Piezoelectric ceramic intelligent structure and method for embedding piezoelectric ceramic intelligent structure into metal matrix

A technology of piezoelectric ceramics and smart structures, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. Hysteresis and other problems, to achieve the effect of fast reaction speed, reducing gas content and inhibiting growth mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

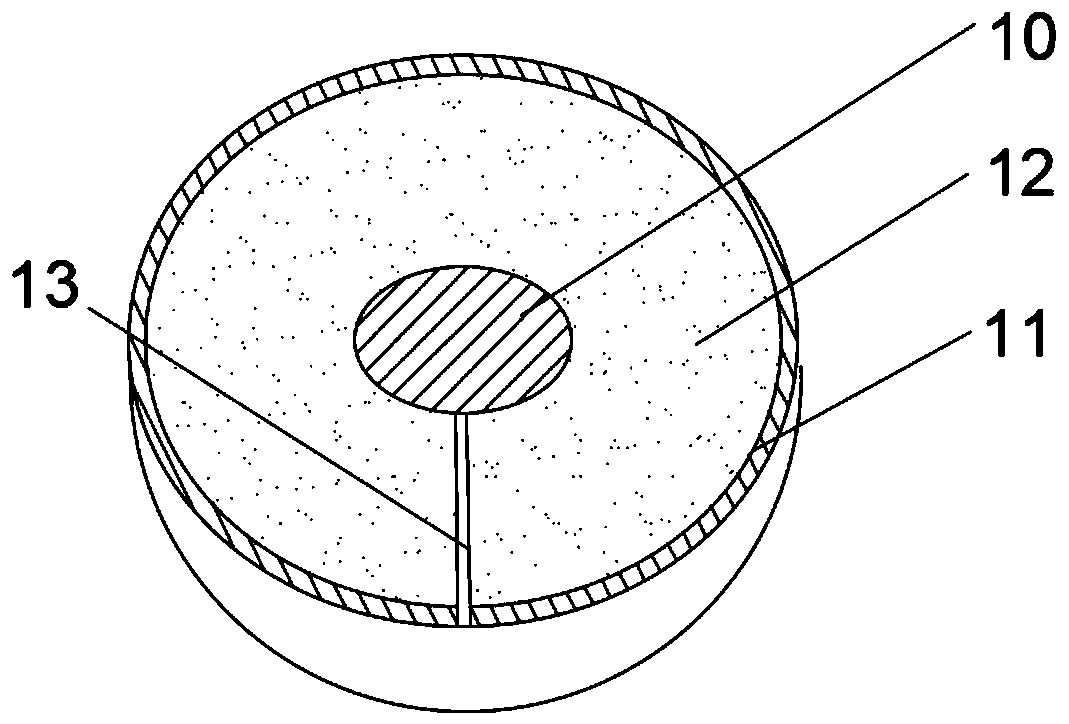

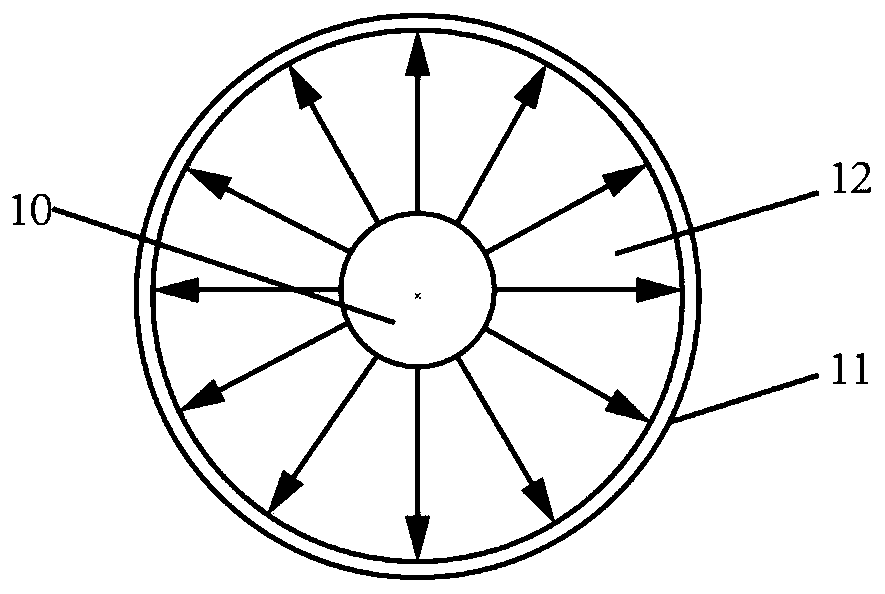

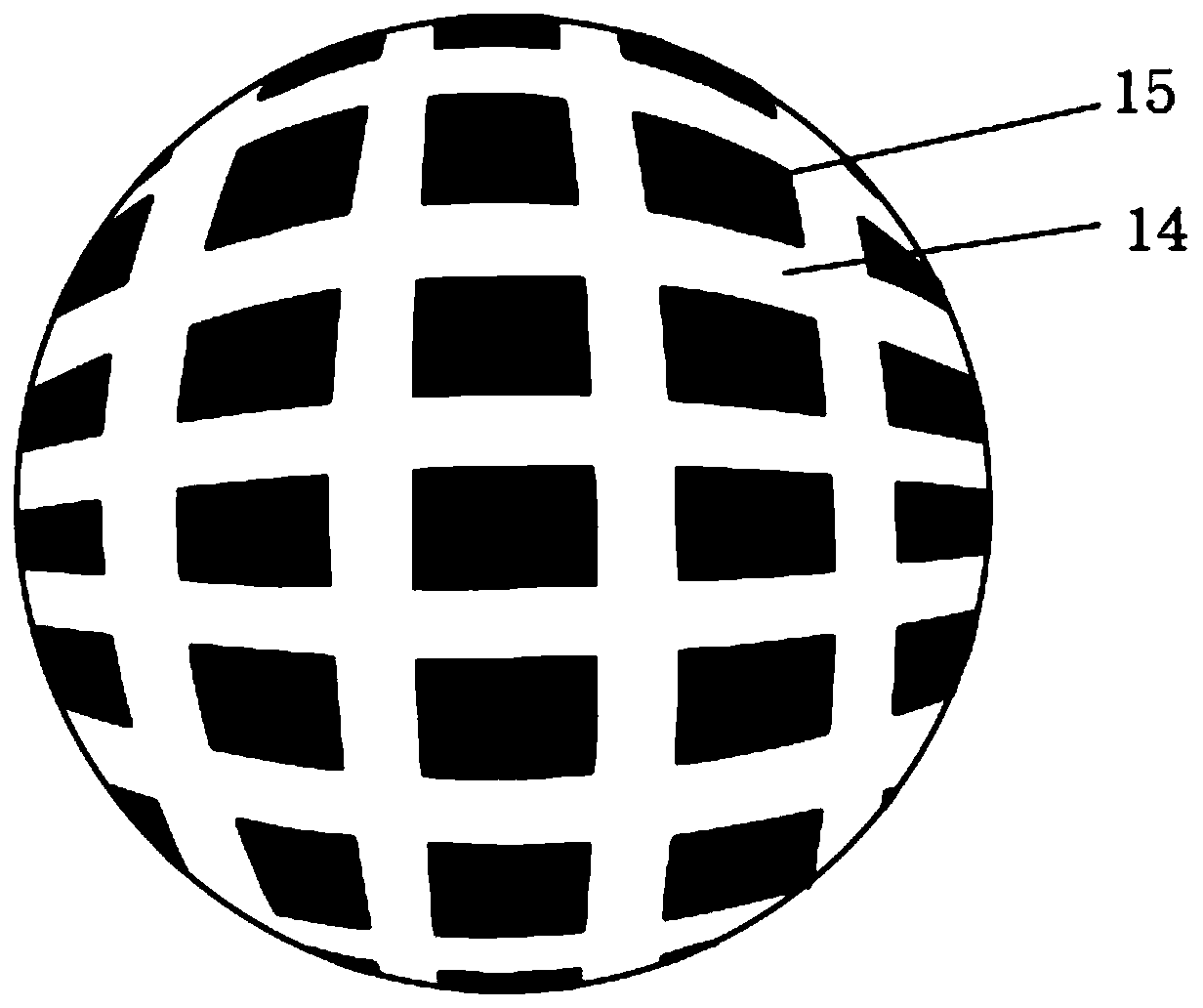

[0040] see Figure 1-3 , this embodiment provides a piezoelectric ceramic smart structure, including a piezoelectric ceramic spherical shell 12, the middle of the piezoelectric ceramic spherical shell 12 is provided with a spherical metal core 10 as an internal electrode, the piezoelectric ceramic The outer surface of the ceramic spherical shell 12 is provided with a metal plating layer 11 as an external electrode, and the piezoelectric ceramic spherical shell 12 is provided with a lead channel 13 for leading out internal electrodes. The outer surface of the piezoelectric ceramic spherical housing 12 is divided into electrodes to form an array of pressure sensors arranged equidistantly.

[0041] In this embodiment, the outer surface of the metal coating 11 can also be sprayed with a high-temperature-resistant insulating paint layer, using water-based inorganic heat-resistant materials, pure inorganic polymer high-temperature solutions, and pigments that are finished with high-...

Embodiment 2

[0048] see Figure 4-7 , the present embodiment provides a method for embedding a piezoelectric ceramic smart structure into a metal matrix, the steps of which include:

[0049] (1) The piezoelectric ceramic material is made into a clay-like mixture, and placed in a mold together with the spherical metal inner core 10 as an internal electrode, pressurized and sintered to form a piezoelectric ceramic spherical shell 12, and the piezoelectric ceramic spherical shell 12 is left with A lead wire channel 13 leading out the internal electrodes;

[0050] Specifically, after weighing by electronic balance according to the composition of the piezoelectric ceramic material, the raw materials are weighed, and the ingredients are mixed by ball milling; the ingredients are dried and ground for 24 hours; the powder is calcined at 1000°C for 3 hours, and then ground again for 48 hours The powder with uniform particles is obtained after screening, and an organic solvent is added to make a cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com