Piezoelectric optoelectronic material for degradation of organic pollutants and degradation method thereof

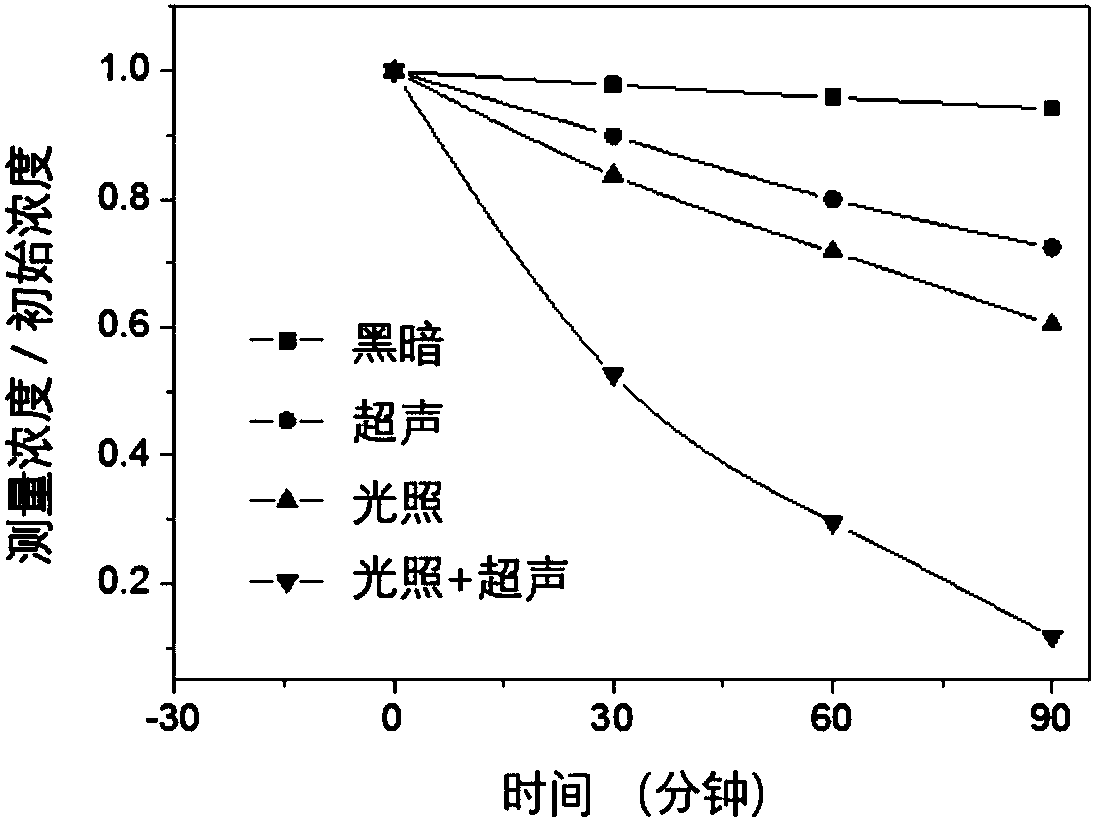

A technology of organic pollutants and optoelectronics, applied in the field of pollutant treatment, can solve the problem that the ability to degrade pollutants cannot meet the requirements, and achieve the effects of stable performance, strong adsorption capacity and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Two-dimensional KNbO 3 Concrete preparation examples of nanosheets:

[0042] (1) Weigh 1.403g KOH and 0.35g Nb 2 o 5 , successively added to a 100mL beaker containing 25mL of ethylene glycol;

[0043] (2) Place the beaker containing the above mixed solution on a magnetic stirrer (stirring speed: 500rpm) and stir for 45 minutes to fully disperse;

[0044] (3) Put the above mixed solution into a polytetrafluoroethylene lining, and heat at 200° C. for 12 hours.

[0045] (4) After cooling to room temperature, wash with distilled water and ethanol for more than three times, and dry to obtain a white product.

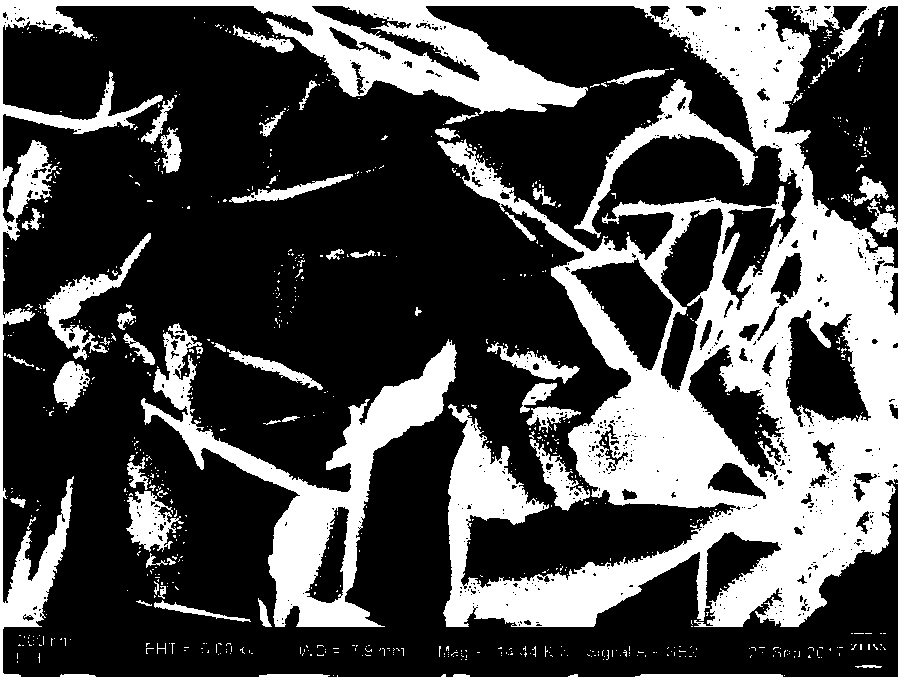

[0046] (5) Grind the above white product with an agate mortar for 5 minutes, place the obtained powder in a muffle furnace, and then calcinate it at 900°C for 2 hours to obtain a two-dimensional KNbO with a thickness of 50nm and a length of 300nm 3 Nanosheets.

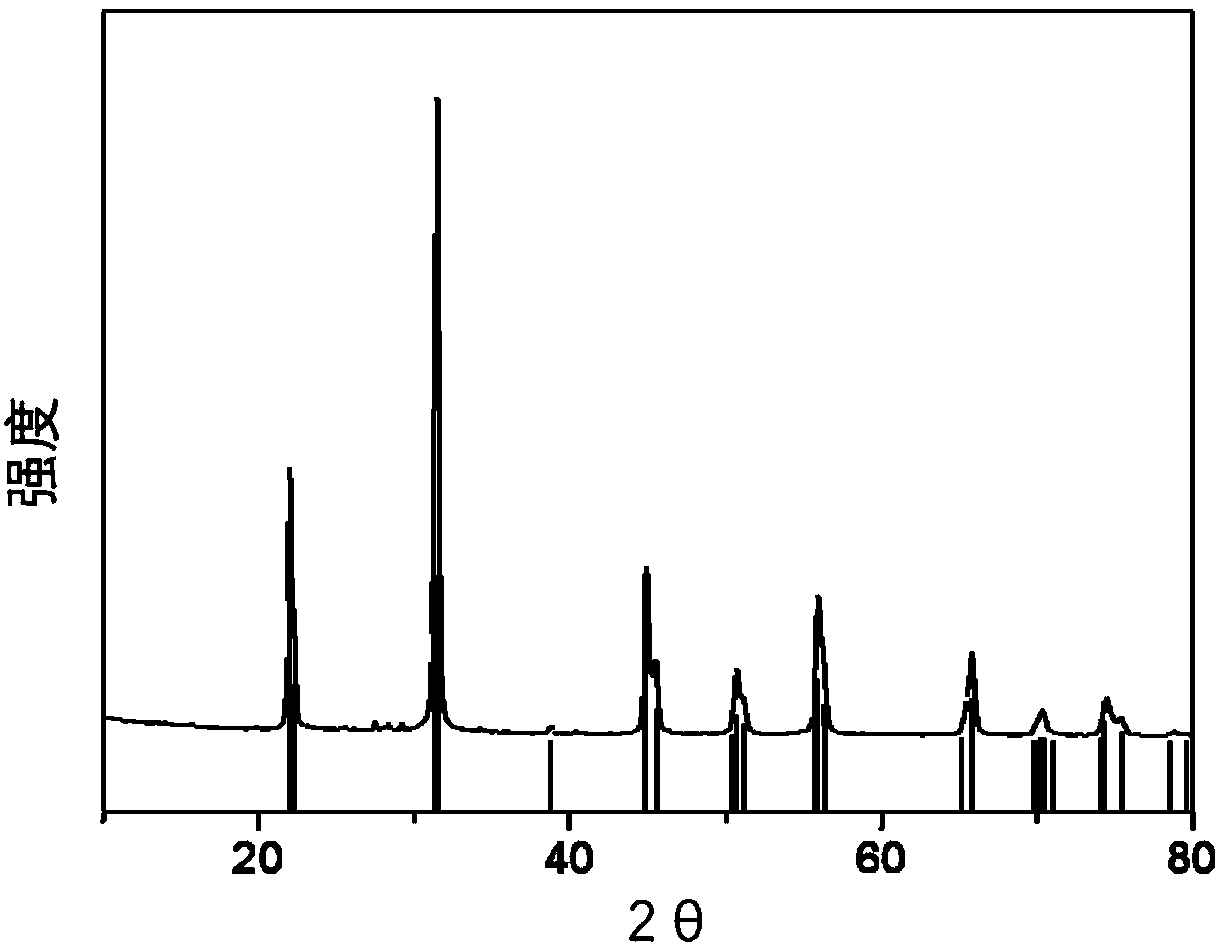

[0047] see figure 1 , figure 2 , KNbO prepared by the present invention 3 Nanosheets, under SEM ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com