Piezoelectric material having high piezoelectricity performance and temperature stability in wide temperature range and application thereof

A piezoelectric material, high voltage technology, applied in the field of piezoelectric material, doped PMN-PT material formulation, can solve the problems of unstable piezoelectric performance, difficult to obtain hard doping, complex, etc., to achieve high voltage. The effect of constant, significant application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to 0.63Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.35PbTiO 3 -0.02BaTiO 3 +0.005MnO 2 The stoichiometric ratio of +0.005MgO will be PbO, MgCO 3 、TiO 2 , Nb 2 o 5 、BaCO 3 , MnO 2 For batching, deionized water was used as the medium, mixed by a planetary ball mill for 5 hours, the powder was fully dried and synthesized at 850°C for 4 hours, and then planetary ball milled again for 6 hours to obtain the doped PMN-PT ceramic powder; The binder polyvinyl butyral is formed by dry pressing and then sintered at 1150° C. to obtain the piezoelectric material.

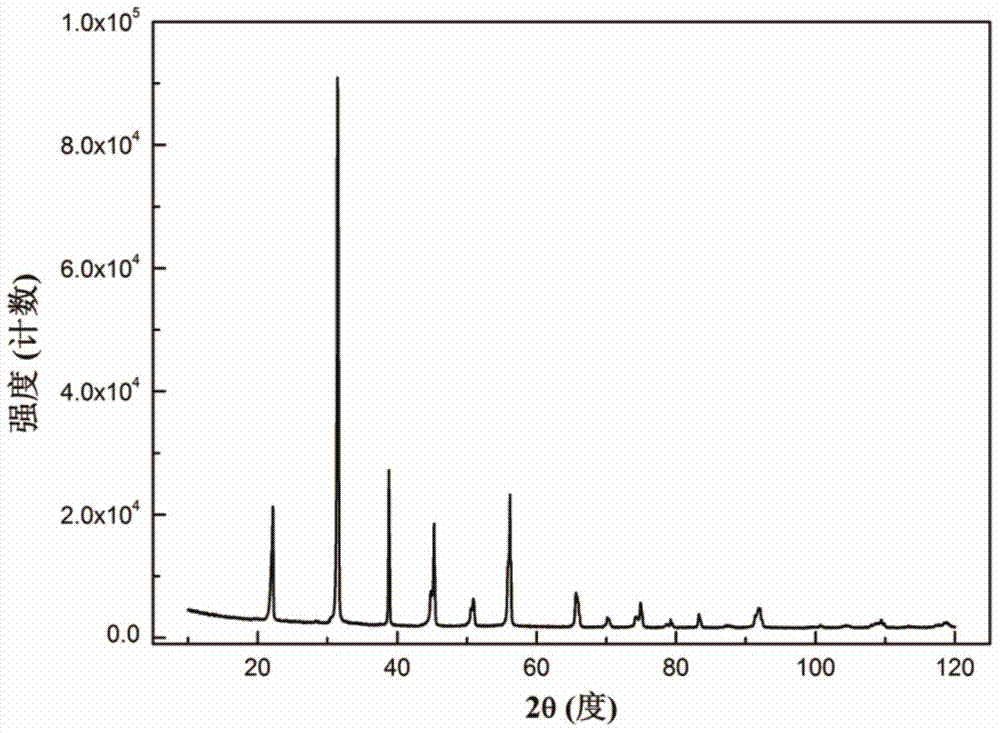

[0021] figure 1 For the XRD spectrogram of the piezoelectric material that the present embodiment obtains, by figure 1 It can be seen that the piezoelectric material is a pure phase ABO 3 Structure, no pyrochlore phase.

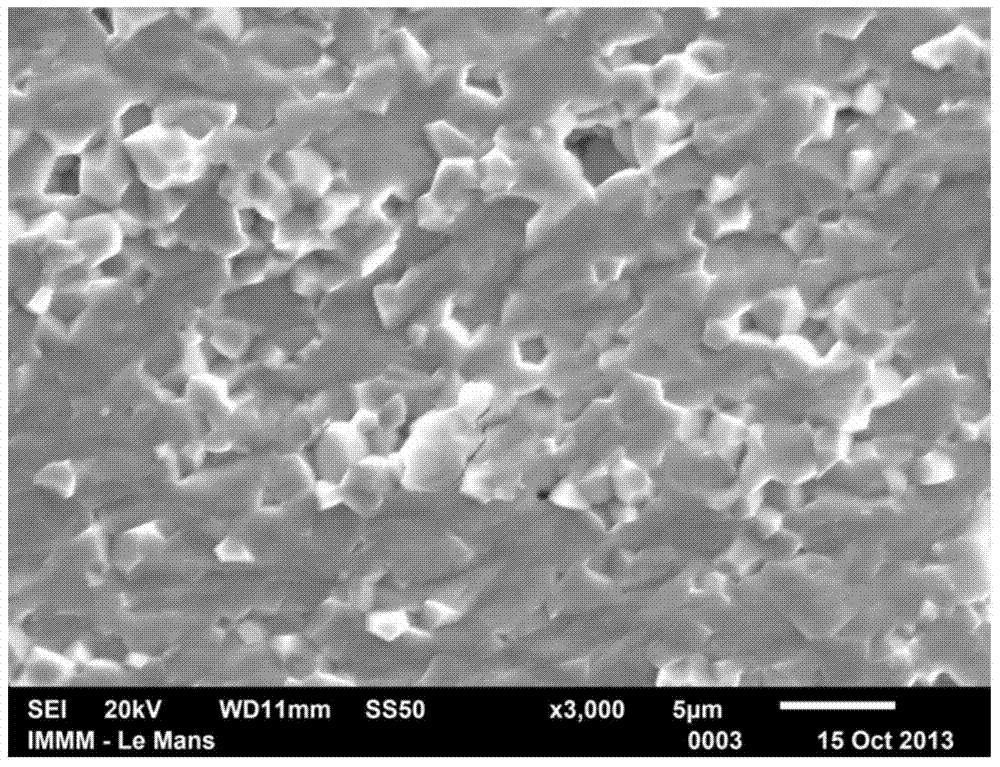

[0022] figure 2 For the SEM photo of the piezoelectric material that this embodiment obtains, by figure 2 It can be seen that the piezoelectric material has extremely high density.

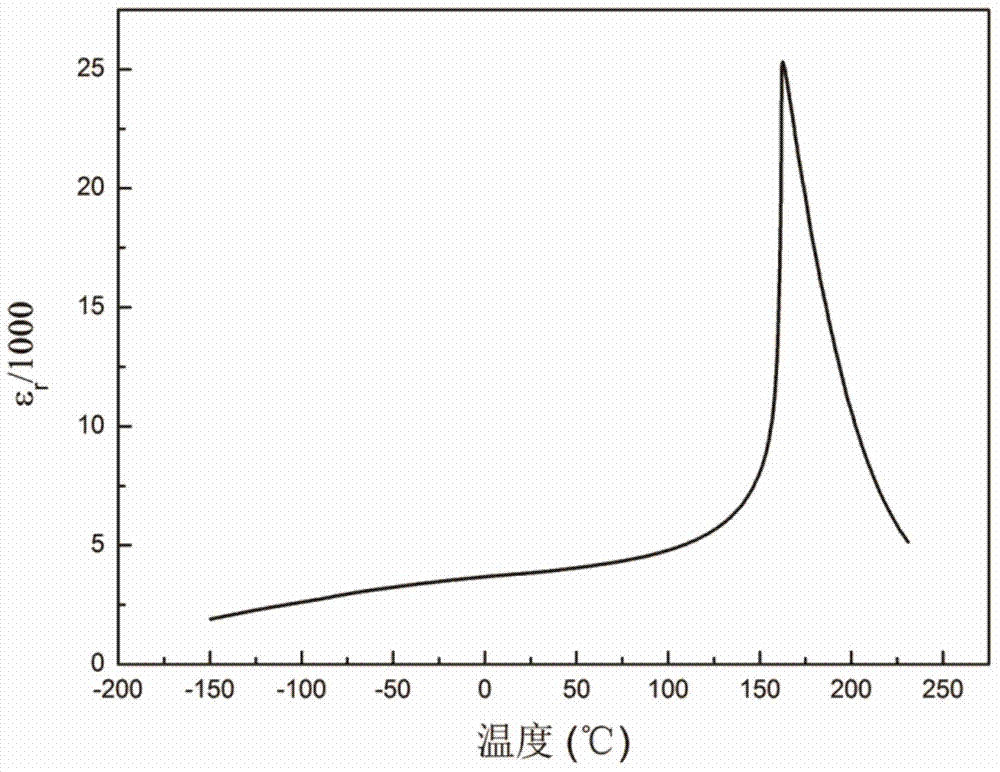

[0023] ...

Embodiment 2

[0027] According to 0.62Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.35PbTiO 3 -0.03BaTiO 3 +0.005MnO 2 The stoichiometric ratio of +0.002MgO+0.003ZnO will PbO, MgCO 3 , ZnO, TiO2 , Nb 2 o 5 、BaCO 3 , MnO 2 For batching, deionized water is used as the medium, mixed by planetary ball mill for 5 hours, the powder is fully dried and synthesized at 850°C for 4 hours, and then planetary ball milled again for 6 hours to obtain the doped PMN-PT ceramic powder; add The binder polyvinyl butyral is formed by dry pressing and then sintered at 1300° C. to obtain the piezoelectric material.

[0028] After testing, the Curie temperature of the piezoelectric material obtained in this example is 162°C, and the piezoelectric d at normal temperature 33 510pC / N; in the temperature range of -75~85℃, d 31 Stabilized at about 175pC / N.

[0029] Figure 5 The piezoelectricity d of the piezoelectric material obtained in this example 31 with d 33 Variation curve with temperature, by Figure 5 It can be see...

Embodiment 3

[0032] According to 0.62Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.3PbTiO 3 -0.08BaTiO 3 +0.005MnO 2 The stoichiometric ratio of +0.05MgO+0.03ZnO will PbO, MgCO 3 , ZnO, TiO 2 , Nb 2 o 5 、BaCO 3 , MnO 2 For batching, use deionized water as the medium, mix by ball milling for 5 hours, the powder is fully dried and synthesized at 850°C for 4 hours, and then ball milled again for 6 hours to obtain the doped PMN-PT ceramic powder; add bonding Agent polyvinyl butyral, after dry pressing and sintering at 1200°C, the piezoelectric material is obtained.

[0033] After testing, the Curie temperature of the piezoelectric material obtained in this example is 140°C, and the piezoelectric d at normal temperature 33 It is 400C / N; in the temperature range of -75~85℃, d 31 Stabilized at about 125pC / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com