High-performance piezoelectric ceramic and preparation method thereof

A piezoelectric ceramics, high-performance technology, applied in the field of piezoelectric ceramics, can solve the problems of general performance of piezoelectric ceramics in PZT system, and achieve the effects of excellent performance, high quality factors, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

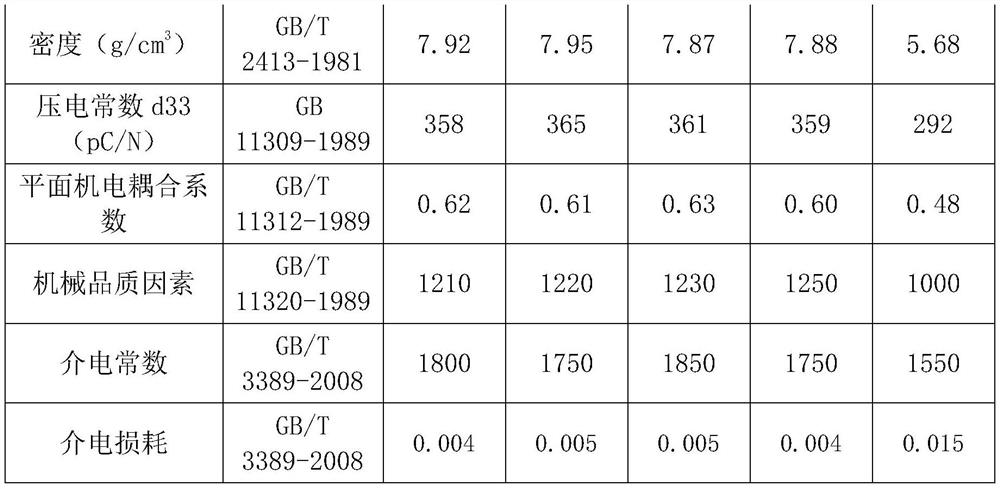

Examples

Embodiment 1

[0030] The general chemical formula of the high-performance piezoelectric ceramic is:

[0031] Pb 0.953 Sr 0.047 (Mg 1 / 3 Nb 2 / 3 ) 0.6 Zr 0.25 Ti 0.6 o 3 +0.7%CeO 2 +0.2%PbO+0.1%CuO+0.25%Nb 2 o 5 ;

[0032] A preparation method of high-performance piezoelectric ceramics, comprising the following steps:

[0033] 1) with Pb 3 o 4 , MgO, Nb 2 o 5 As raw material, according to Pb (Mg 1 / 3 Nb 2 / 3 )O 3 Mix the ratio evenly, and incubate at a temperature of 1100°C for 3 hours to synthesize Pb(Mg 1 / 3 Nb 2 / 3 )O 3 ;

[0034] 2) with Pb(Mg 1 / 3 Nb 2 / 3 )O 3 , SrCO 3 、TiO 2 , ZrO 2 , Nb 2 o 5 , CeO 2 , PbO, CuO as raw materials, according to Pb 0.953 Sr 0.047 (Mg 1 / 3 Nb 2 / 3 ) 0.6 Zr 0.25 Ti 0.6 o 3 +0.7%CeO 2 +0.2%PbO+0.1%CuO+0.25%Nb 2 o 5 Mix the ratio evenly, and obtain Pb after 4 hours of heat preservation at 850°C 0.953 Sr 0.047 (Mg 1 / 3 Nb 2 / 3 ) 0.6 Zr 0.25 Ti 0.6 o 3 +0.7%CeO 2 +0.2%PbO+0.1%CuO+0.25%Nb 2 o 5 mixed powder;

[0035] 3) P...

Embodiment 2

[0038] The general chemical formula of the high-performance piezoelectric ceramic is:

[0039] Pb 0.927 Sr 0.073 (Mg 1 / 3 Nb 2 / 3 ) 0.2 Zr 0.4 Ti 0.4 o 3 +0.4%CeO 2 +0.3%PbO+0.3%CuO+0.2%Nb 2 o 5 ;

[0040] A preparation method of high-performance piezoelectric ceramics, comprising the following steps:

[0041] 1) with Pb 3 o 4 , MgO, Nb 2 o 5 As raw material, according to Pb (Mg 1 / 3 Nb 2 / 3 )O 3 Mix the ratio evenly, and synthesize Pb(Mg 1 / 3 Nb 2 / 3 )O 3 ;

[0042] 2) with Pb(Mg 1 / 3 Nb 2 / 3 )O 3 , SrCO 3 、TiO 2 , ZrO 2 , Nb 2 o 5 , CeO 2 , PbO, CuO as raw materials, according to Pb 0.927 Sr 0.073 (Mg 1 / 3 Nb 2 / 3 ) 0.2 Zr 0.4 Ti 0.4 o 3 +0.4%CeO 2 +0.3%PbO+0.3%CuO+0.2%Nb 2 o 5 Mix the ratio evenly, and obtain Pb after incubating at 900°C for 3 hours 0.927 Sr 0.073 (Mg 1 / 3 Nb 2 / 3 ) 0.2 Zr 0.4 Ti 0.4 o 3 +0.4%CeO 2 +0.3%PbO+0.3%CuO+0.2%Nb 2 o 5 mixed powder;

[0043] 3) Will

[0044] Pb 0.927 Sr 0.073 (Mg 1 / 3 Nb 2 / 3 ) 0.2 Zr 0...

Embodiment 3

[0047] The general chemical formula of the high-performance piezoelectric ceramic is:

[0048] Pb 0.942 Sr 0.058 (Mg 1 / 3 Nb 2 / 3 ) 0.3 Zr 0.25 Ti 0.45 o 3 +0.6%CeO 2 +0.23%PbO+0.2%CuO+0.1%Nb 2 o 5 ;

[0049] A preparation method of high-performance piezoelectric ceramics, comprising the following steps:

[0050] 1) with Pb 3 o 4 , MgO, Nb 2 o5 As raw material, according to Pb (Mg 1 / 3 Nb 2 / 3 )O 3 Mix the ratio evenly, and synthesize Pb(Mg 1 / 3 Nb 2 / 3 )O 3 ;

[0051] 2) with Pb(Mg 1 / 3 Nb 2 / 3 )O 3 , SrCO 3 、TiO 2 , ZrO 2 , Nb 2 o 5 , CeO 2 , PbO, CuO as raw materials, according to Pb 0.942 Sr 0.058 (Mg 1 / 3 Nb 2 / 3 ) 0.3 Zr 0.25 Ti 0.45 o 3 +0.6%CeO 2 +0.23%PbO+0.2%CuO+0.1%Nb 2 o 5 Mix the ratio evenly, and obtain Pb after incubating at 900°C for 3 hours 0.942 Sr 0.058 (Mg 1 / 3 Nb 2 / 3 ) 0.3 Zr 0.25 Ti 0.45 o 3 +0.6%CeO 2 +0.23%PbO+0.2%CuO+0.1%Nb 2 o 5 mixed powder;

[0052] 3) Pb 0.942 Sr 0.058 (Mg 1 / 3 Nb 2 / 3 ) 0.3 Zr 0.25 Ti ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com