Bismuth ferrite-lead titanate-barium titanate ternary-system high-temperature piezoelectric ceramics and preparation method thereof

A ternary system, high-temperature piezoelectric technology, applied in the field of multi-system high-temperature piezoelectric materials and their preparation, can solve the problems of lowering the Curie temperature of BF-PT piezoelectric materials and limiting the application field of BF-PT piezoelectric materials, etc. Achieve the effect of obvious advantages in piezoelectric coefficient, high voltage constant and high voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

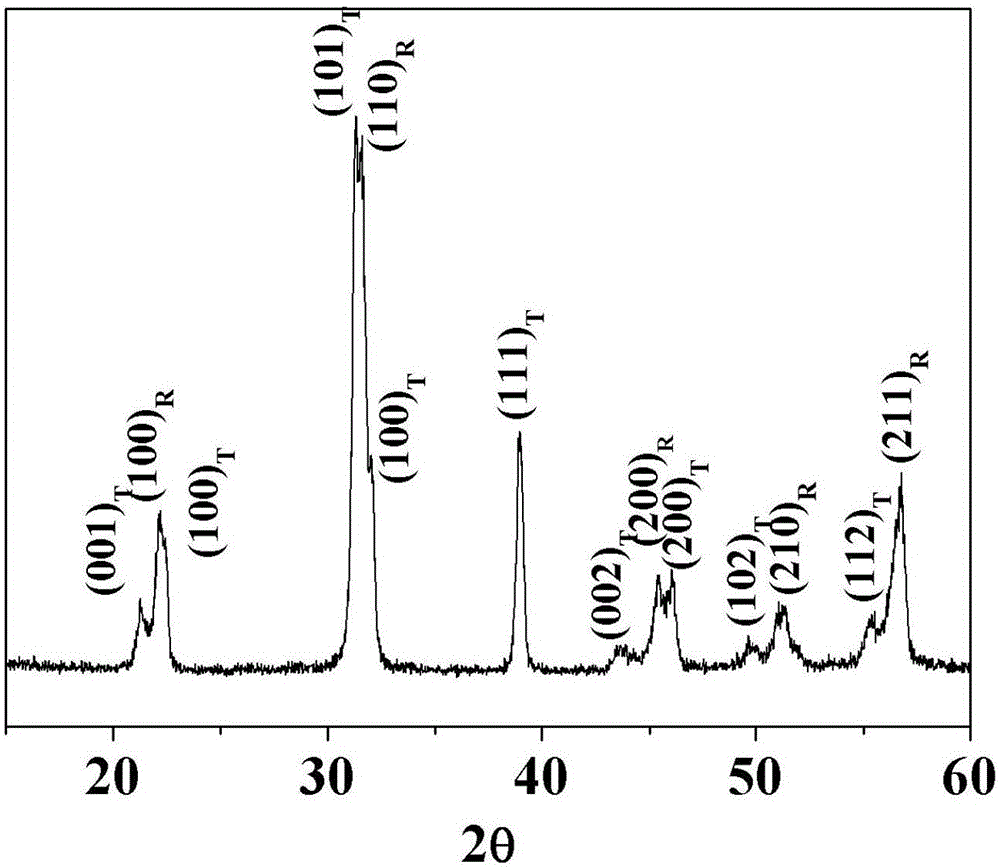

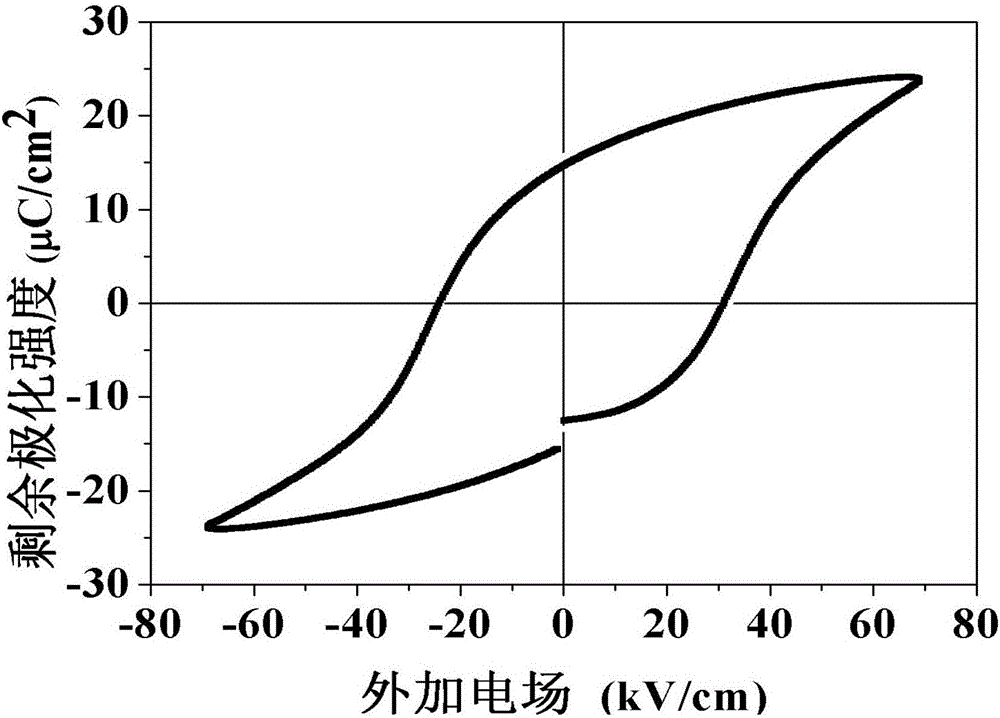

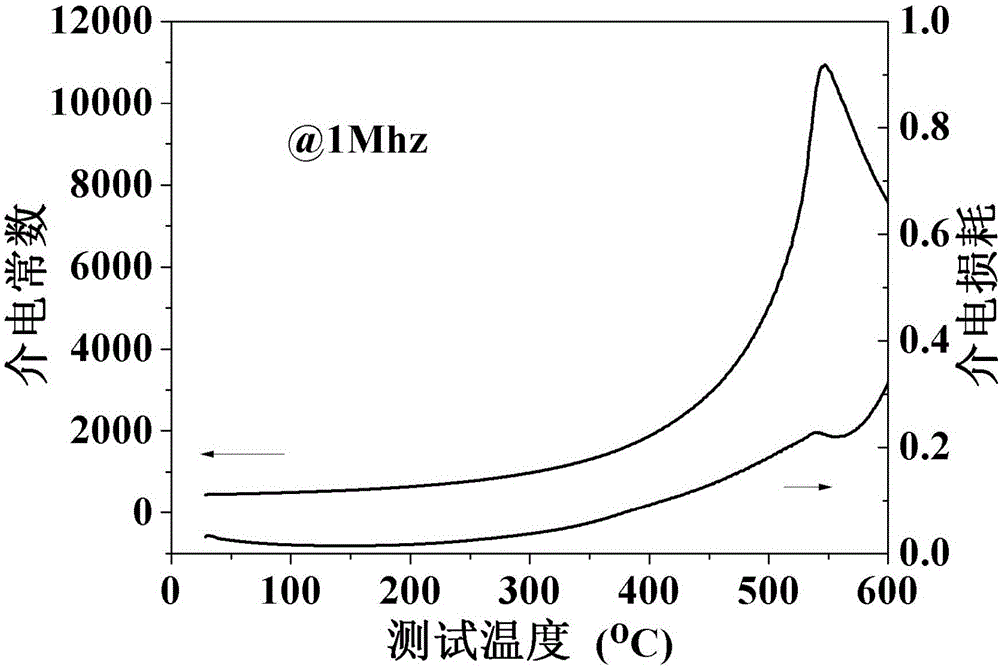

[0039]In this embodiment, a bismuth ferrite-lead titanate-barium titanate ternary system high-temperature piezoelectric ceramic has the following composition and mass mole fraction: 0.62BF-0.23PT-0.15BT, that is, BF-PT- The molar ratio of bismuth ferrite: lead titanate: barium titanate in the BT ternary system is 0.62:0.23:0.15. The components of this embodiment are selected using (1-x)BF-xPT-0.15BT, x=0.23, and the content of barium titanate in the third component is 15%.

[0040] The preparation method of bismuth ferrite-lead titanate-barium titanate ternary system high-temperature piezoelectric ceramics in this embodiment includes the following steps:

[0041] a. Synthesis of BF-PT-BT powder:

[0042] With pure Bi 2 o 3 , Fe 2 o 3 , PbO, TiO 2 、BaCO 3 and MnO 2 As a raw material, the above-mentioned raw materials are weighed according to the stoichiometric ratio required for the BF-PT-BT ternary system whose chemical formula is 0.62BF-0.23PT-0.15BT, that is, to cont...

Embodiment 2

[0063] This embodiment is basically the same as Embodiment 1, especially in that:

[0064] In this embodiment, a bismuth ferrite-lead titanate-barium titanate ternary system high-temperature piezoelectric ceramic has the following composition and mass mole fraction: 0.66BF-0.19PT-0.15BT, that is, BF-PT- The molar ratio of bismuth ferrite: lead titanate: barium titanate in the BT ternary system is 0.66:0.19:0.15. The components of this embodiment are selected using (1-x)BF-xPT-0.15BT, x=0.19, and the content of barium titanate in the third component is 15%.

[0065] The preparation method of bismuth ferrite-lead titanate-barium titanate ternary system high-temperature piezoelectric ceramics in this embodiment includes the following steps:

[0066] a. Synthesis of BF-PT-BT powder:

[0067] With pure Bi 2 o 3 , Fe 2 o 3 , PbO, TiO 2 、BaCO 3 and MnO 2 As a raw material, the above-mentioned raw materials are weighed according to the stoichiometric ratio required for the BF...

Embodiment 3

[0088] This embodiment is basically the same as the previous embodiment, and the special features are:

[0089] In this embodiment, a bismuth ferrite-lead titanate-barium titanate ternary system high-temperature piezoelectric ceramic has the following composition and mass mole fraction: 0.58BF-0.27PT-0.15BT, that is, BF-PT- The molar ratio of bismuth ferrite: lead titanate: barium titanate in the BT ternary system is 0.58:0.27:0.15. The components of this embodiment are selected using (1-x)BF-xPT-0.15BT, x=0.27, and the content of barium titanate in the third component is 15%.

[0090] The preparation method of bismuth ferrite-lead titanate-barium titanate ternary system high-temperature piezoelectric ceramics in this embodiment includes the following steps:

[0091] a. Synthesis of BF-PT-BT powder:

[0092] With pure Bi 2 o 3 , Fe 2 o 3 , PbO, TiO 2 、BaCO 3 and MnO 2 As a raw material, the above-mentioned raw materials are weighed according to the stoichiometric rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com