Composite piezoelectric film and preparation method thereof

A technology of piezoelectric thin film and composite film, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, material selection for piezoelectric devices or electrostrictive devices It can solve the problems that the piezoelectric performance cannot fully meet the market performance requirements, and achieve the effects of high piezoelectric constant, high sensitivity and strong environmental adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

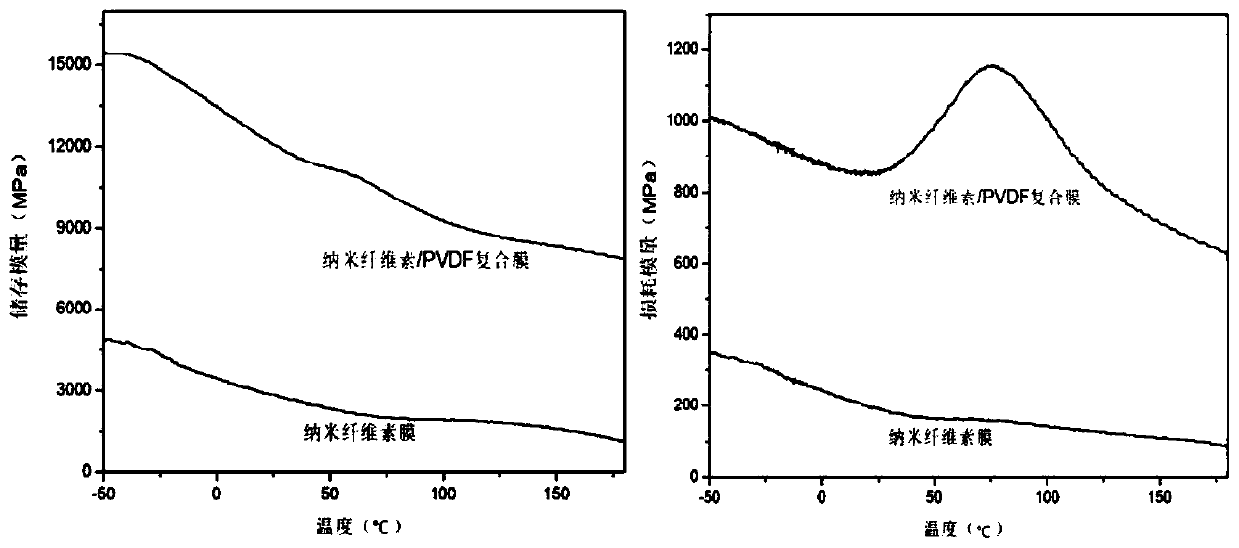

[0034] A preparation method of nano-cellulose / PVDF composite piezoelectric film includes the following steps: first add 2 parts of PVDF powder and 50 parts of N,N-dimethylformamide into a reactor, start a stirrer to adjust the speed to 300r / min, stirring for 30min, after PVDF is dissolved, add 2 parts of nano cellulose and 0.05 part of Mxene, adjust the stirring speed to 1000r / min, stir for 5min, use vacuum filtration (0.1MPa, 1h), hot press drying (100℃ , 5min) method to prepare nanocellulose / PVDF composite membrane; then put the prepared film into a polarizer, polarization voltage 8000V, polarization temperature 60℃, polarization time 20min, to obtain nanocellulose / PVDF composite Piezoelectric film.

Embodiment 2

[0036] A preparation method of nano-cellulose / PVDF composite piezoelectric film includes the following steps: first add 2 parts of PVDF powder and 50 parts of N-methylpyrrolidone into a reactor, start a stirrer to adjust the speed to 300r / min, and stir 30min, after PVDF is dissolved, add 3 parts of nanocellulose, 0.05 part of Mxene, adjust the stirring speed to 1000r / min, stir for 5min, use vacuum filtration (0.1MPa, 1h), hot press drying (100℃, 5min) Preparation of nano-cellulose / PVDF composite membrane; then put the prepared film into a polarizer, polarization voltage 10000V, polarization temperature 60°C, polarization time 30min, to obtain nano-cellulose / PVDF composite piezoelectric film.

Embodiment 3

[0038] A preparation method of nano-cellulose / PVDF composite piezoelectric film includes the following steps: first add 2 parts of PVDF powder and 50 parts of dimethyl sulfoxide into a reactor, start a stirrer to adjust the speed to 300r / min, and stir 30min, after PVDF is dissolved, add 4 parts of nanocellulose, 0.05 part of Mxene, adjust the stirring speed to 1000r / min, stir for 5min, use vacuum filtration (0.1MPa, 1h), hot press drying (100℃, 5min) Preparation of nano-cellulose / PVDF composite membrane; then put the prepared film into a polarizer, polarization voltage of 12000V, polarization temperature of 60°C, and polarization time of 60 minutes to obtain nano-cellulose / PVDF composite piezoelectric film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com