A kind of preparation method of zinc oxide thick film for ultrasonic transducer

A technology of ultrasonic transducer and zinc oxide film, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problem of affecting the piezoelectricity of the resonance mode of the material thickness, the reduction of the surface compactness of the zinc oxide film, Surface unevenness and other problems, to achieve the effect of increased grain size, reduced porosity, and uniform grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a zinc oxide thick film for an ultrasonic transducer, comprising the steps of:

[0032] Step 1: Select an N-type single-sided polished silicon wafer with (100) crystal orientation as the substrate, the thickness of the silicon wafer is 500 μm, cut the silicon wafer into a substrate of 2 cm × 2 cm, and clean the substrate, such as figure 1 shown. The cleaning method is as follows: use acetone, alcohol, and deionized water to ultrasonically clean for 10 minutes each, and then dry the operation surface with nitrogen gas after cleaning.

[0033] Step 2: Prepare a zinc oxide seed layer on the substrate using a magnetron sputtering process, such as figure 2 shown. The sputtering parameters are as follows: 99.9% pure zinc oxide target, substrate vacuum 8×10 -4 pa, argon flow rate 40 sccm, oxygen flow rate 5 sccm, pressure 0.02mbar, power 120W, room temperature, sputtering time: 7.5min, sputtering thickness about 0.1μm.

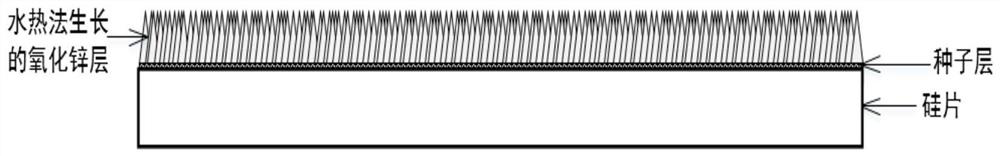

[0034] Step 3: Use the hydroth...

Embodiment 2

[0039] A method for preparing a zinc oxide thick film for an ultrasonic transducer, comprising the steps of:

[0040] Step 1: Select an N-type single-sided polished silicon wafer with (100) crystal orientation as the substrate, the thickness of the silicon wafer is 500 μm, cut the silicon wafer into a substrate of 2 cm×2 cm, and clean the substrate. The cleaning method is as follows: use acetone, alcohol, and deionized water to ultrasonically clean for 10 minutes each, and then dry the operation surface with nitrogen gas after cleaning.

[0041] Step 2: A zinc oxide seed layer is prepared on the substrate using a magnetron sputtering process. The sputtering parameters are as follows: 99.9% pure zinc oxide target, substrate vacuum 8×10 -4 pa, argon flow rate 40 sccm, oxygen flow rate 5 sccm, pressure 0.02mbar, power 120W, room temperature, sputtering time: 7.5min, sputtering thickness about 0.1μm.

[0042] Step 3: using a hydrothermal growth method to prepare a zinc oxide fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com