Doping type tantalic acid gallium-lanthanum crystal for high-temperature piezoelectric devices and preparation method thereof

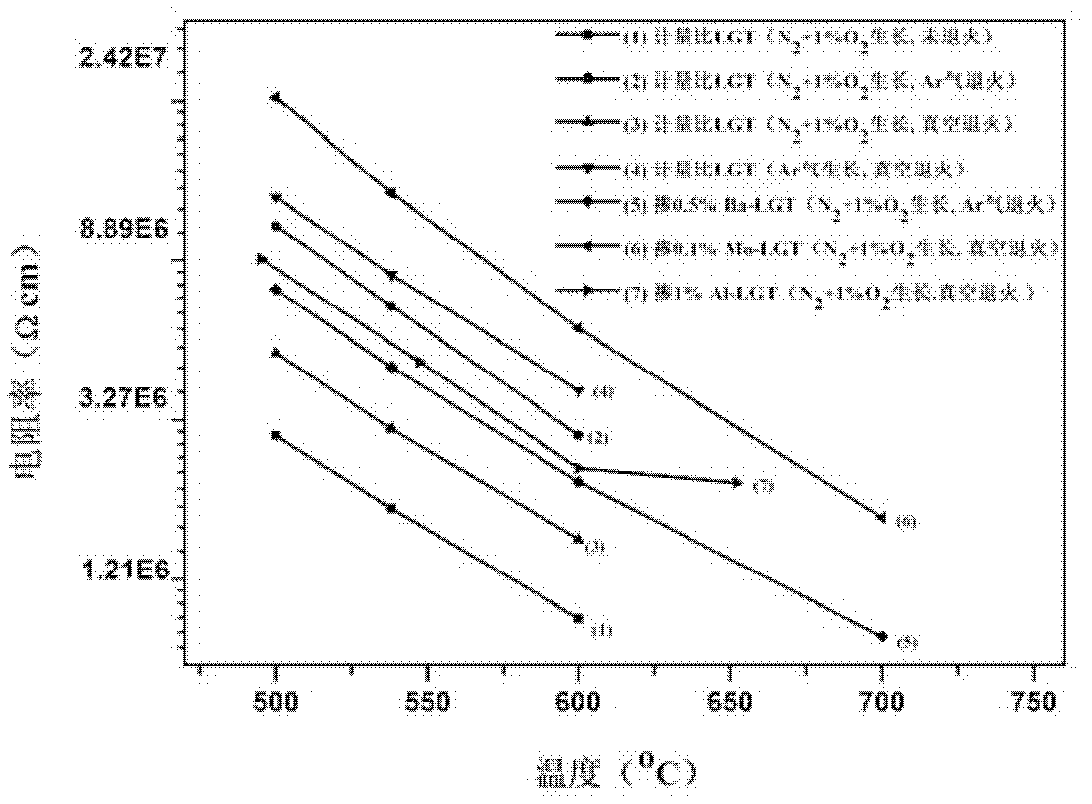

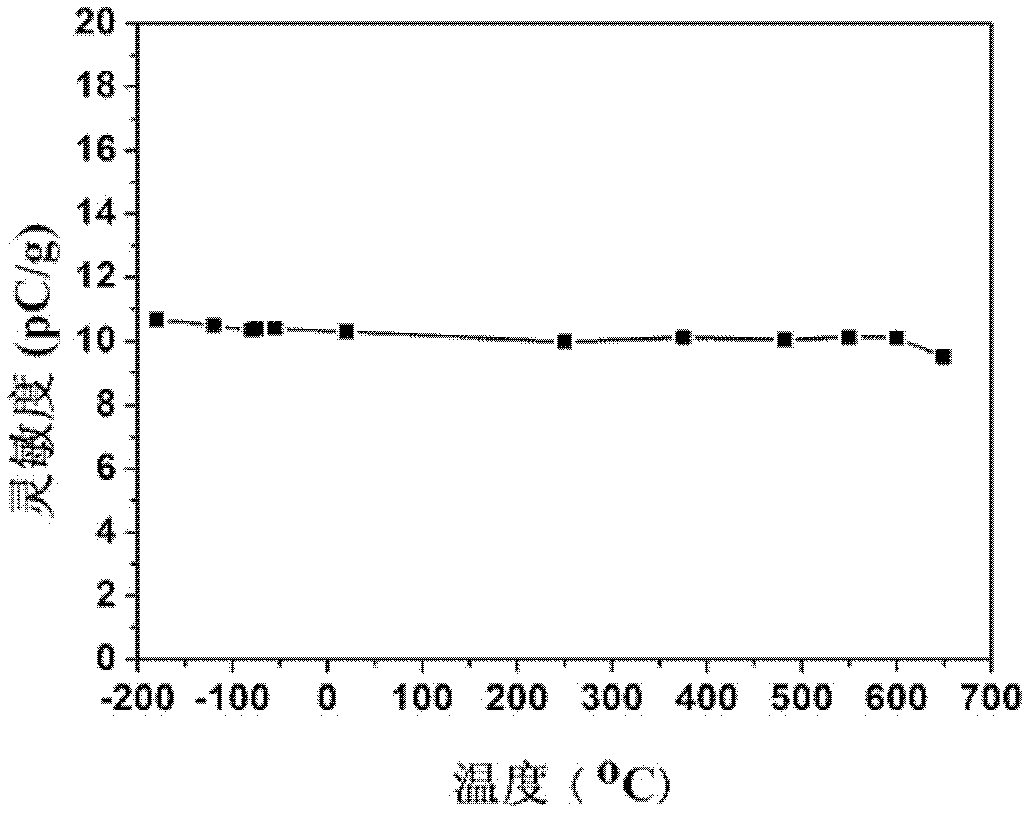

A gallium lanthanum tantalate, doped technology, which is used in the field of doped gallium lanthanum tantalate crystals and its preparation for high-temperature piezoelectric devices, can solve the problems of rarely reported devices, and achieve large-scale, high electromechanical Coupling factor, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of 0.5% Ba:La 3 Ta 0.5 Ga 5.5 o 14

[0041] (1) use La 2 o 3 , Ga 2 o 3 、 Ta 2 o 5 and BaCO 3 As the initial raw material, roasted and dried

[0042] Press 0.5%Ba:La first 3 Ta 0.5 Ga 5.5 o 14 The molar ratio of chemical formula La 2 o 3 : Ga 2 o 3 : Ta 2 o 5 : BaCO 3 =1.5:2.75:0.25:0.0015 Weigh the raw material and add more Ga 2 o 3 Mass 1% Ga 2 o 3 , so that Ga 2 o 3 Excess 1%, mixed, compacted, put into alumina crucible and sintered at 1200°C for 24 hours to obtain Ba-LGT polycrystalline material.

[0043] (2) Place the Ba-LGT polycrystalline material in a platinum or iridium crucible. Single crystal furnace is evacuated and filled with protective gas: N 2 +(1~2vol%O 2 ), using intermediate frequency heating, heating up to melt the raw material and keeping it warm for 2 to 10 hours, and then cooling down to near the melting point; inserting the seed crystal, using the LGT seed crystal in the z direction, necking and shoulderi...

Embodiment 2

[0047] Preparation of 0.1% Mo:La 3 Ta 0.5 Ga 5.5 o 14

[0048] (1) use La 2 o 3 , Ga 2 o 3 、 Ta 2 o 5 and MoO 3 As the initial raw material, roasted and dried

[0049] Press 0.1%Mo:La first 3 Ta 0.5 Ga 5.5 o 14 The molar ratio of chemical formula La 2 o 3 : Ga 2 o 3 : Ta 2 o 5 : MoO 3 =1.5:2.75:0.25:0.003 Weigh the raw material and add more Ga 2 o 3 2% Ga by mass 2 o 3 , so that Ga 2 o 3 2% in excess, mixed evenly, compacted, put into an alumina crucible and sintered at 1200° C. for 20 hours to obtain Mo-LGT polycrystalline material.

[0050] (2) Place the Mo-LGT polycrystalline material in a platinum or iridium crucible. Vacuumize the single crystal furnace, fill it with 100% Ar gas, use intermediate frequency heating, heat up to melt the raw material and keep it warm for 2 to 10 hours, and then cool down to near the melting point; put in the seed crystal, use the LGT seed crystal in the x direction, and Put the shoulders behind the neck and grow ...

Embodiment 3

[0054] Preparation of 1% Al:La 3 Ta 0.5 Ga 5 o 14 (i.e. La 3 Ta 0.5 Ga 5 al 0.5 o 14 )

[0055] (1) use La 2 o 3 , Ga 2 o 3 、 Ta 2 o 5 and Al 2 o 3 As the initial raw material, roasted and dried

[0056] Press 1%Al:La first 3 Ta 0.5 Ga 5 o 14 The molar ratio of chemical formula La 2 o 3 : Ga 2 o 3 : Ta 2 o 5 :Al 2 o 3 = 1: 1.667: 0.167: 0.136 Weigh the raw material and add more Ga 2 o 3 2% Ga by mass 2 o 3 , so that Ga 2 o 3 Excessive 2%, mixed, compacted, put into alumina crucible and sintered at 1250°C for 18 hours to obtain Al-LGT polycrystalline material.

[0057] (2) Place the Al-LGT polycrystalline material in a platinum or iridium crucible. The single crystal furnace is evacuated and filled with protective gas: Ar+1~2%O 2 (volume percentage), using intermediate frequency heating, heat up to melt the raw material and keep it warm for 2 to 10 hours, and then cool down to near the melting point; put in the seed crystal, use the LGT seed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com