Method for removing arsenic and antimony in industrial wastewater by using smelting furnace slag

A technology for industrial wastewater and slag, which is applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as difficult to sell, easy to dissolve, low level of resource utilization, etc., to reduce treatment costs and chemical properties Stable, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

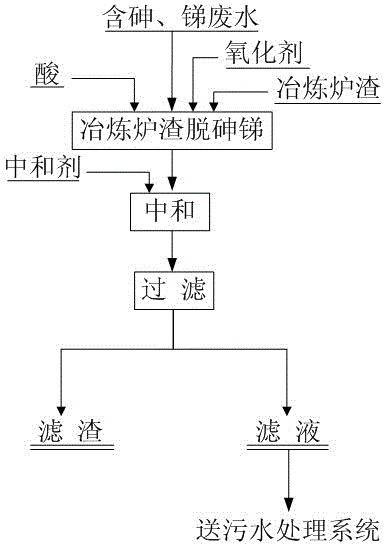

Method used

Image

Examples

example 1

[0025] Example 1. The flue gas purification cleaning solution of a lead-fired smelting furnace contains As 9.42g / L and Sb 1.34g / L, take 1L of it, add sulfuric acid to adjust the acidity, and control the pH = 2.5.

[0026] Add 50g of pre-broken 100 mesh lead smelting water quenching slag, main components: Fe 26.3%, Zn 3.4%, Si 11.5%, Ca 3.9%, Al 0.9%, Mg 2.5%, As 0.08%, Sb 0.18%; then Add oxidant manganese dioxide 19g.

[0027] The solution was heated to 60°C and kept for 2.5h.

[0028] Add neutralizing agent magnesium oxide for neutralization, and control pH=7.

[0029] Filter the solution to obtain a filtrate containing As 0.17mg / L and Sb 0.38mg / L. This is a qualified filtrate, and it will be sent to the sewage treatment system for purification to further remove other impurities. The removal rate of arsenic and antimony in wastewater is close to 100%.

[0030] The filtered residue is sent to the residue yard for stockpiling.

example 2

[0031] Example 2. Flue gas purification cleaning liquid of a copper pyrometallurgy furnace, containing As 20.78g / L, Sb 0.79g / L, take 1L of it and add nitric acid to adjust acidity, control pH=3.5. Add 40g of tailings iron slag (fineness 150 mesh) produced by copper smelting slag after slag selection, main components: Fe42.5%, Zn 2.1%, Cu 0.34%, Si 14.6%, Ca 4.5%, Al 1.4% , Mg 0.9%, As 0.09%, Sb 0.08%; then add oxidant hydrogen peroxide 45ml.

[0032] The solution was heated to 95°C and kept for 1 h. Add neutralizing agent sodium carbonate for neutralization, control pH=8.

[0033] Filter the solution to obtain a filtrate containing As 0.24mg / L and Sb 0.33mg / L. This is a qualified filtrate, which is sent to the sewage treatment system for purification to further remove other impurities. The removal rate of arsenic and antimony in wastewater is close to 100%.

[0034] The filtered residue is sent to the residue yard for stockpiling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com