Preparation method of solid-state sodium-ion battery electrolyte

A sodium ion battery and electrolyte technology, applied in the field of sodium ions, can solve the problems of high ionic conductivity, no

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

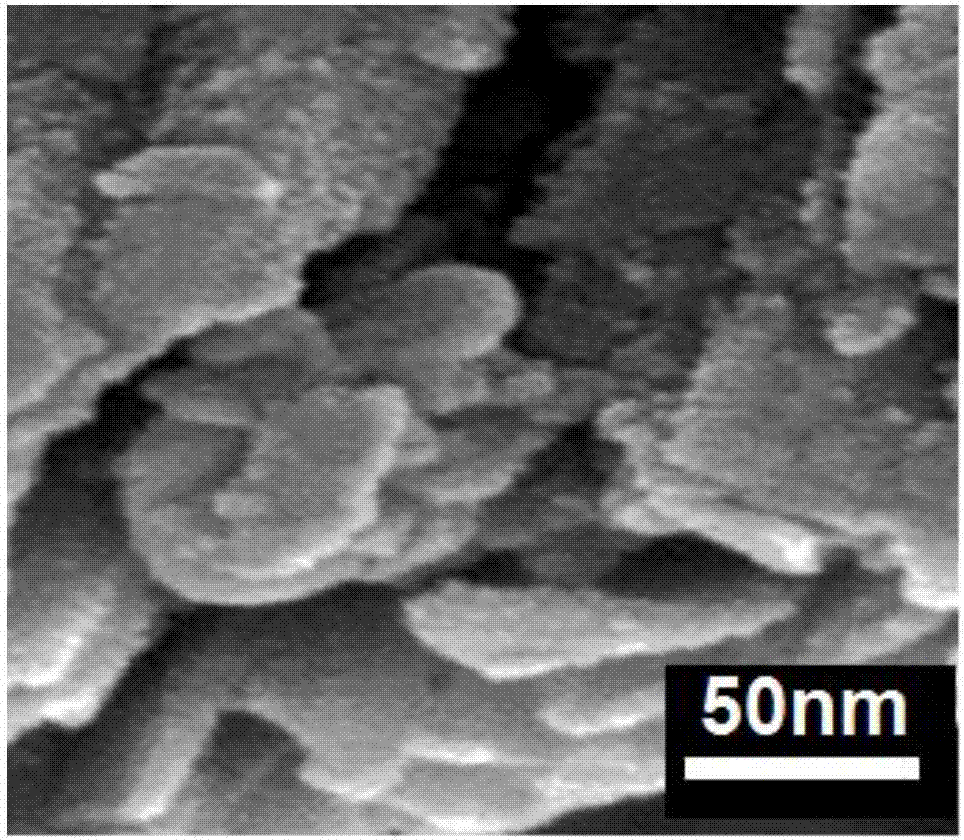

Image

Examples

Embodiment 1

[0012] Sodium sulfide was dissolved in 1L deionized water, then placed in a constant temperature water bath and heated to 80°C, and sodium antimonate and NH4F were added. The mass ratio of sodium sulfide, sodium antimonate and NH4F was 3.5:1:0.5. After stirring slowly for 4 hours, it was naturally cooled to room temperature and filtered. Dry in an oven at 80°C, then place in a furnace tube, heat to 300°C for reaction, pass in argon as a protective atmosphere, keep warm for 2 hours, and then cool naturally to room temperature. form Na 2.5 Sb 3.5 f 0.5 Lumpy solid where x = 0.5.

Embodiment 2

[0014] Sodium sulfide was dissolved in 1L of deionized water, then placed in a constant temperature water bath and heated to 90°C, and sodium antimonate and NH4F were added. The mass ratio of sodium sulfide, sodium antimonate and NH4F was 1.5:1:2.5. After stirring slowly for 3 hours, it was naturally cooled to room temperature and filtered. Dry it in an oven at 80°C, then put it in a furnace tube, heat it to 400°C for reaction, pass in argon as a protective atmosphere, keep it warm for 1 hour, and then cool it down to room temperature naturally. form Na 0.5 Sb 1.5 f 0.5 Lumpy solid where x = 2.5.

Embodiment 3

[0016] Sodium sulfide was dissolved in 1L deionized water, then placed in a constant temperature water bath and heated to 90°C, and sodium antimonate and NH4F were added. The mass ratio of sodium sulfide, sodium antimonate and NH4F was 3:1:1. After stirring slowly for 3 hours, it was naturally cooled to room temperature and filtered. Dry in an oven at 70°C, then place in a furnace tube, heat to 300°C for reaction, pass in argon as a protective atmosphere, keep warm for 1 hour, and then cool naturally to room temperature. form Na 2 Sb 3 F Lumpy solid where x=1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com