Environment-friendly high-efficiency automobile ceramic brake pad and production method thereof

A brake pad, high-efficiency technology, applied in the field of ceramic automobile brake pads, can solve the problems of poor thermal stability of semi-metallic brake pads, poor wear resistance of asbestos brake pads, affecting the comfort of drivers and passengers, etc., to achieve good safety and normal operation, Effect of long service life and stable friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

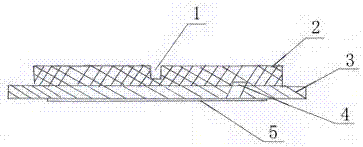

[0015] Example 1, such as figure 1 As shown, an environmentally friendly and efficient ceramic brake pad includes a friction layer 2, a steel back 3, a sound-absorbing sheet 5, an alarm card 4 and a groove 1, and is characterized in that the friction layer is prepared by weight ratio of the following components: Aramid fiber 8, ceramic fiber 5, 98% copper fiber 5, potassium titanate whisker 1.5, calcium carbonate whisker 29, aluminum oxide 6, antimony sulfide 1, 40 mesh high carbon graphite 1.6, calcined petroleum coke 11.3, butyl Cyanide rubber powder 2.8, vermiculite 1.6, friction powder 5.7, barite powder 4.3, light calcium 17.2, phenolic resin 5.

[0016] An environmentally friendly and efficient production method of ceramic brake pads, which is carried out according to the following steps: 1. Weighing, accurately weighing the above-mentioned components according to the weight ratio of the above-mentioned components of the friction layer; 2. Mixing, the weighed Stir and m...

Embodiment 2

[0017] Embodiment 2, an environmentally friendly and efficient ceramic brake pad, including a friction layer 2, a steel back 3, a sound-absorbing sheet 5, an alarm card 4 and a slot 1, is characterized in that the friction layer is prepared by the following components in weight ratio : Aramid fiber 7, ceramic fiber 7, 98% copper fiber 6, potassium titanate whisker 1, calcium carbonate whisker 25.9, aluminum oxide 5, antimony sulfide 1.9, 40 mesh high carbon graphite 1.7, calcined petroleum coke 7.3, NBR powder 2.5, vermiculite 3, friction powder 5.7-15.7, barite powder 4.75, light calcium 22.2, phenolic resin 5.

[0018] Production method is with embodiment 1.

Embodiment 3

[0019] Example 3, an environmentally friendly and efficient ceramic brake pad, including a friction layer 2, a steel back 3, a sound-absorbing sheet 5, an alarm card 4 and a slot 1, characterized in that the friction layer is prepared by the following components in weight ratio : Aramid fiber 7.5, ceramic fiber 8, 98% copper fiber 5.5, potassium titanate whisker 2, calcium carbonate whisker 14, aluminum oxide 7, antimony sulfide 1.5, 40 mesh high carbon graphite 1.5, calcined petroleum coke 21.3, NBR powder 2, vermiculite 2.8, friction powder 10.0, barite powder 4.2, light calcium 13.2, phenolic resin 5.

[0020] Production method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com