High-transparency TPU (Thermoplastic Polyurethane) film for high-speed rail laminating film and preparation method of TPU film

A film and film technology, applied in the field of high-transparency TPU film and its preparation, can solve the problems of dizziness, dazzling, scene deformation, etc., and achieve the effect of reducing usage, improving transparency and mechanical properties, and reducing glare index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]A high-transparency TPU film for high-speed rail film, prepared by the following method:

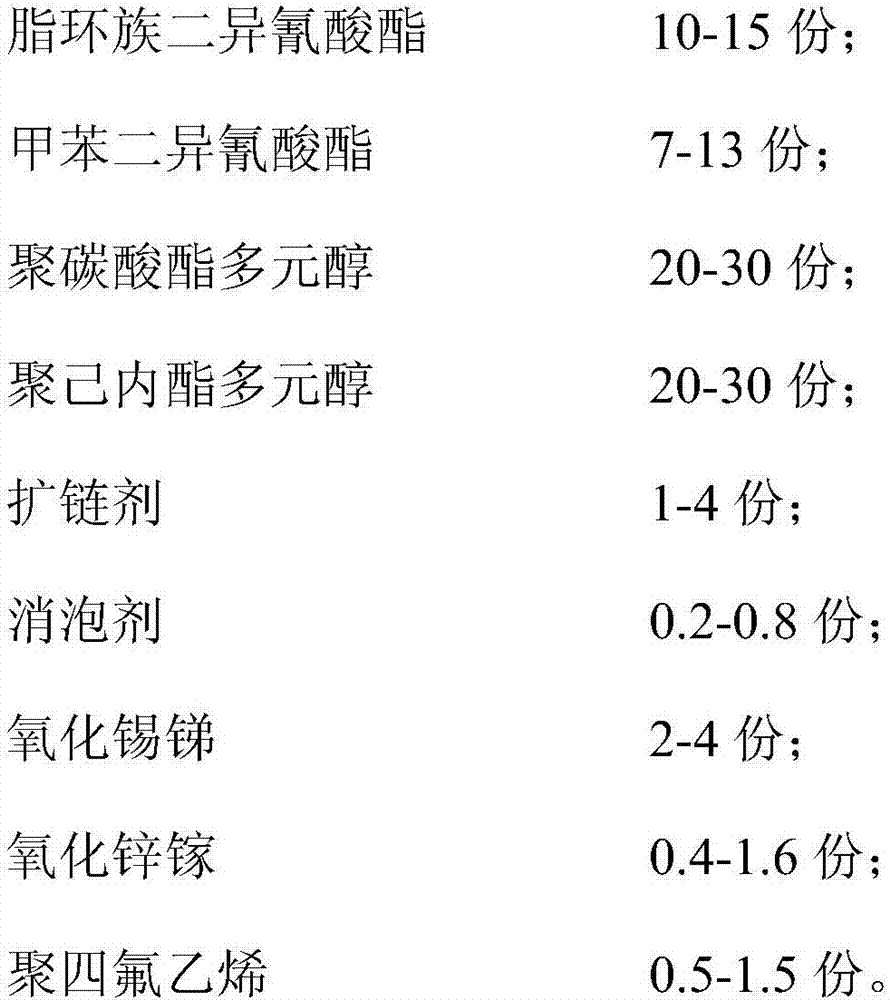

[0037] 1) Raw material and ratio:

[0038]

[0039] 2) Preparation method:

[0040] ① Dry the components at 90°C for 8 hours according to the formula, and then mix them;

[0041] ②The mixed components are extruded through the extruder. The temperature of the solid conveying zone of the extruder is 260°C, the temperature of the material plasticizing zone is 180°C, and the temperature of the melt conveying zone is 320°C.

Embodiment 2

[0043] A high-transparency TPU film for high-speed rail film, prepared by the following method:

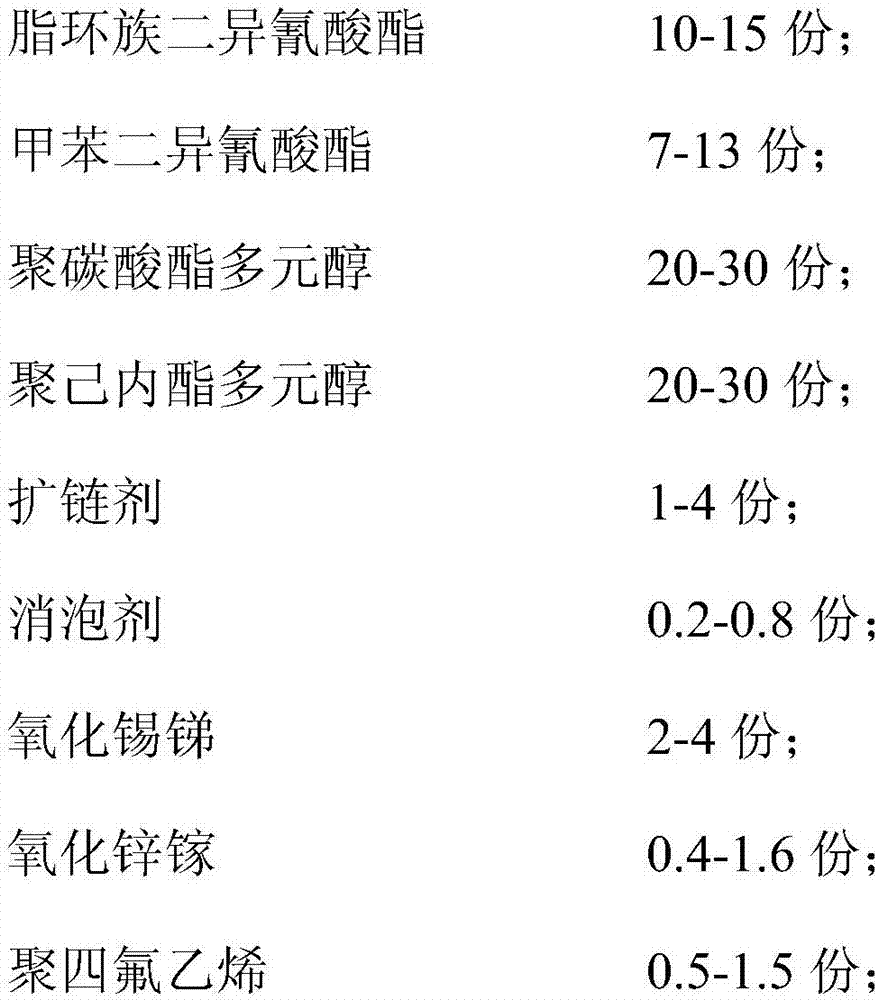

[0044] 1) Raw material and ratio:

[0045]

[0046]

[0047] 2) Preparation method:

[0048] ① Dry the components at 110°C for 4 hours according to the formula, and then mix them;

[0049] ②The mixed components are extruded through the extruder. The temperature of the solid conveying zone of the extruder is 440°C, the temperature of the material plasticizing zone is 860°C, and the temperature of the melt conveying zone is 420°C.

Embodiment 3

[0051] A high-transparency TPU film for high-speed rail film, prepared by the following method:

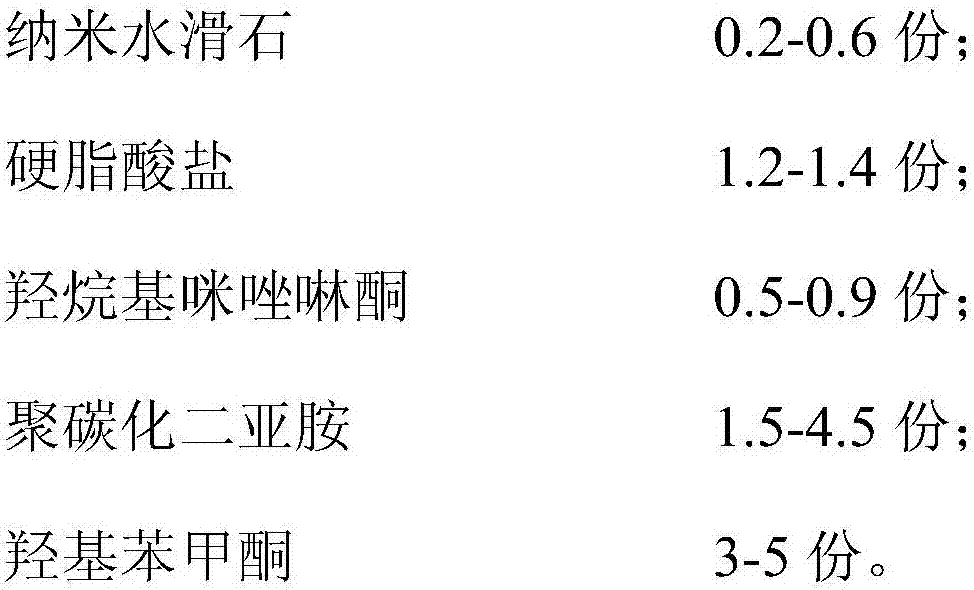

[0052] 1) Raw material and ratio:

[0053]

[0054]

[0055] 2) Preparation method:

[0056] ① Dry the components at 100°C for 6 hours according to the formula, and then mix them;

[0057] ②The mixed components are extruded through the extruder. The temperature of the solid conveying zone of the extruder is 350°C, the temperature of the material plasticizing zone is 520°C, and the temperature of the melt conveying zone is 370°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com