Preparation method of PVC (polyvinyl chloride) waterproof coating

A waterproof coating and preparation process technology, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of uneven fusion and dispersion, affecting performance, low thermal stability and anti-aging performance of polyvinyl chloride, and achieve uniform hydrophobicity, The effect of high adhesive performance and simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

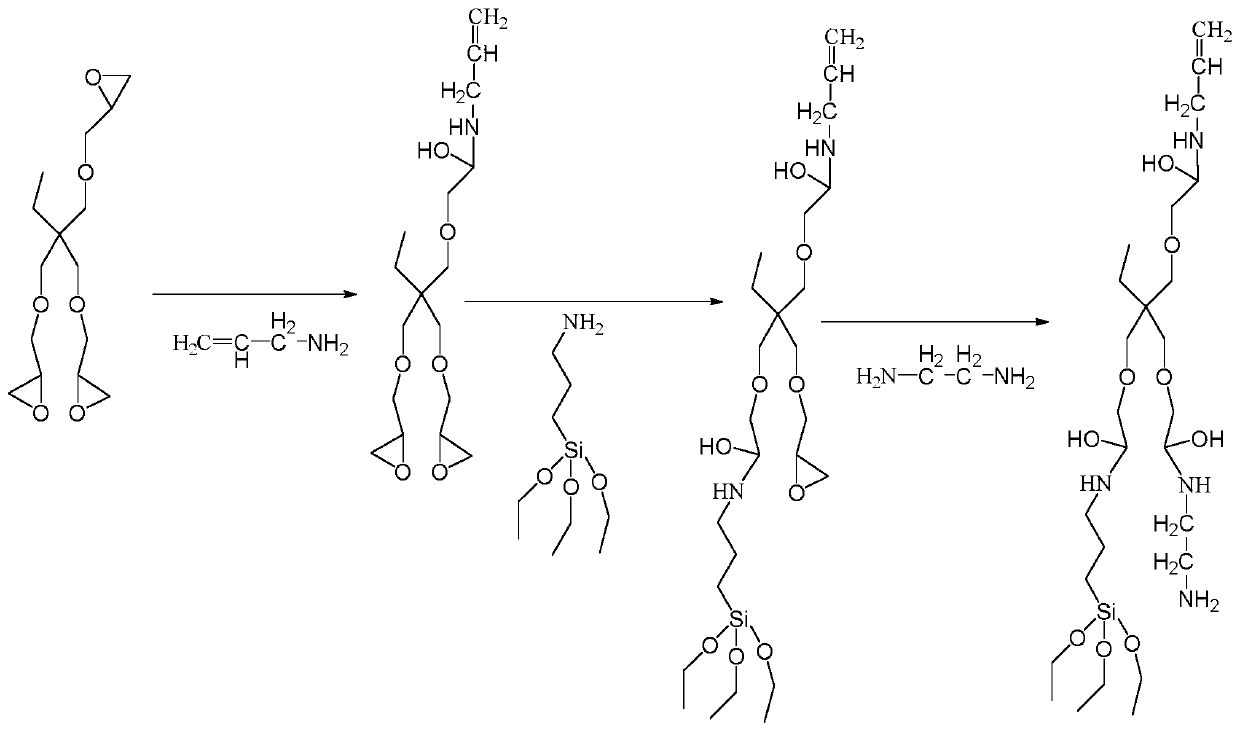

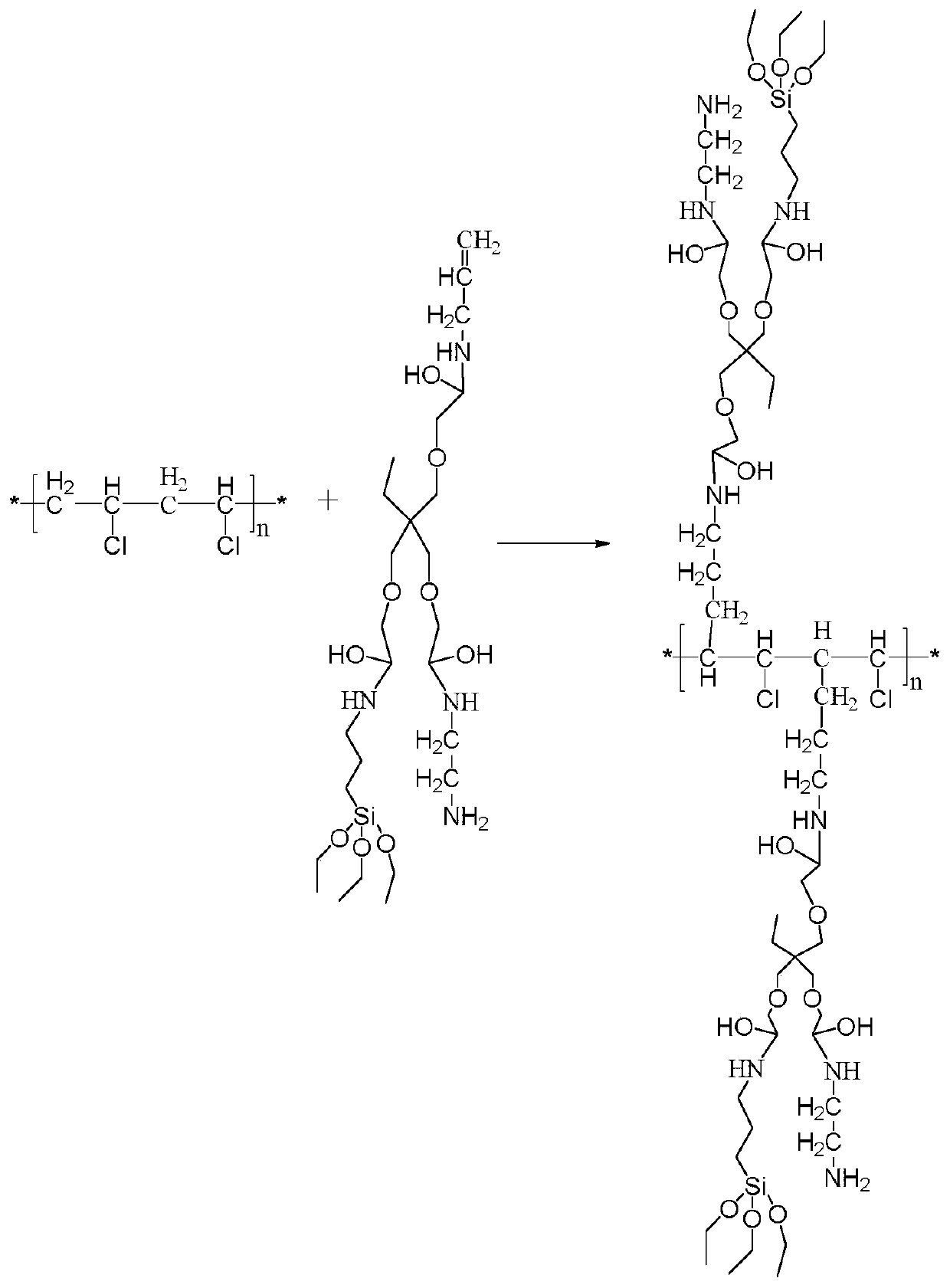

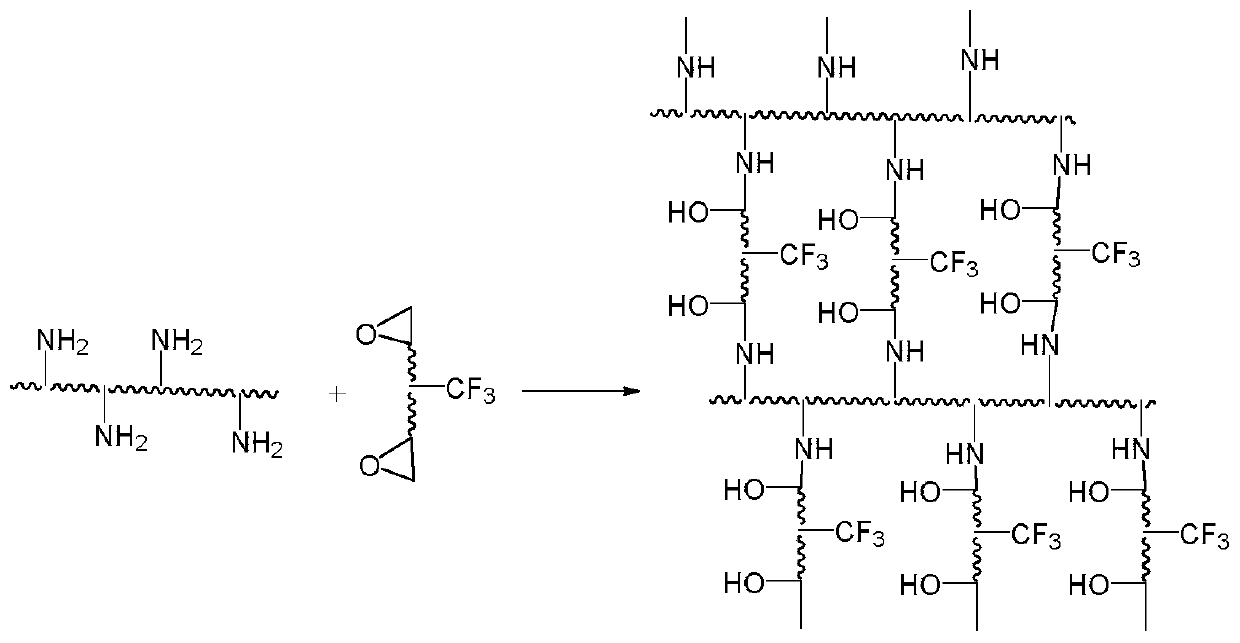

[0030]The concrete preparation process of branched graft modifier is as follows:

[0031] ①Put 3.02kg of trimethylolpropane triglycidyl ether into the reaction kettle, cool down to 5-10°C, add 0.57kg of allylamine dropwise, stir for 3-4 hours, then heat up to 30-35°C for reaction 1- 1.5h, a colorless and transparent solution was obtained;

[0032] ②Add 2.21kgr-aminopropyltriethoxysilane to the reaction kettle in step ①, raise the temperature to 80-90℃ and stir and reflux for 9-10h, then lower it to room temperature and add 0.66kg of ethylenediamine to the reaction kettle, keep the temperature After reflux for 4-5 hours, the product was distilled under reduced pressure to obtain a branched graft modifier.

Embodiment 2

[0034] The concrete preparation process of branched graft modifier is as follows:

[0035] ①Put 3.02kg of trimethylolpropane triglycidyl ether into the reaction kettle, cool down to 5-10°C, add 0.57kg of allylamine dropwise, stir for 3-4 hours, then heat up to 30-35°C for reaction 1- 1.5h, a colorless and transparent solution was obtained;

[0036] ②Add 1.77kgr-aminopropyltriethoxysilane to the reaction kettle in step ①, raise the temperature to 80-90℃ and stir and reflux for 9-10h, then lower it to room temperature and add 0.78kg of ethylenediamine to the reaction kettle, keep the temperature After reflux for 4-5 hours, the product was distilled under reduced pressure to obtain a branched graft modifier.

Embodiment 3

[0038] The concrete preparation process of branched graft modifier is as follows:

[0039] ①Put 3.02kg of trimethylolpropane triglycidyl ether into the reaction kettle, cool down to 5-10°C, add 0.57kg of allylamine dropwise, stir for 3-4 hours, then heat up to 30-35°C for reaction 1- 1.5h, a colorless and transparent solution was obtained;

[0040] ②Add 2.43kgr-aminopropyltriethoxysilane to the reaction kettle of step ①, raise the temperature to 80-90℃ and stir and reflux for 9-10h, then lower it to room temperature and add 0.66kg of ethylenediamine to the reaction kettle, keep the temperature constant After reflux for 4-5 hours, the product was distilled under reduced pressure to obtain a branched graft modifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com