High-thermal-stability proton exchange membrane and preparation method

A technology of proton exchange membrane and high thermal stability, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of proton conduction decline, water instability, etc., and achieve a simple and easy preparation method, Easy to control and promote the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

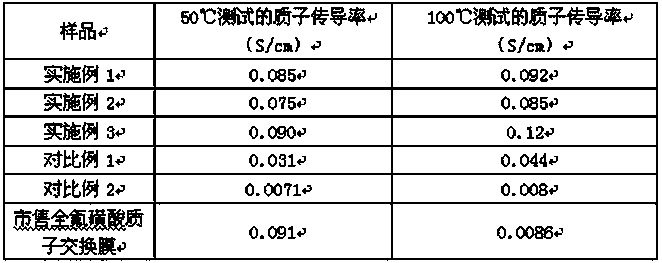

Examples

Embodiment 1

[0033] (1) Treat Nafion resin with liquid nitrogen at a temperature lower than -20°C, and grind it with a jet mill to obtain Nafion resin powder with a particle size of 5-10 microns;

[0034] (2) Add sulfonic acid to silica sol with a mass concentration of 12% to adjust the pH value to 4, then add ethanol to dilute to a mass concentration of 5%, and the spray gun pressure of the high-pressure sprayer is 0.5MPa, so that the diluted silica sol can be evenly sprayed on the Nafion resin On the surface of the powder, the spraying amount is controlled to be 8% of the mass of Nafion resin powder, and it is airtight and aged for 2 days;

[0035] (3) The aging material in step (2) is dried by centrifugal spraying, and the hot air at 100°C is sent into the drying chamber in a spiral shape, and the aging material is sent to the centrifugal spray dryer, and the aging material is dispersed into particles after high-speed centrifugal rotation , and dried by hot air flow to obtain Nafion res...

Embodiment 2

[0039] (1) Treat Nafion resin with liquid nitrogen at a temperature lower than -20°C, and grind it with a jet mill to obtain Nafion resin powder with a particle size of 5-10 microns;

[0040] (2) Add sulfinic acid to silica sol with a mass concentration of 12% to adjust the pH value to 5, then add ethanol to dilute to a mass concentration of 5%, and the spray gun pressure of the high-pressure sprayer is 0.5MPa, so that the diluted silica sol can be evenly sprayed on Nafion On the surface of resin powder, control the amount of spraying to be 10% of the mass of Nafion resin powder, and store it in airtight storage for 2 days;

[0041] (3) The aging material in step (2) is dried by centrifugal spraying, and the hot air at 100°C is sent into the drying chamber in a spiral shape, and the aging material is sent to the centrifugal spray dryer, and the aging material is dispersed into particles after high-speed centrifugal rotation. , and dried by hot air flow to obtain Nafion resin p...

Embodiment 3

[0045] (1) Treat Nafion resin with liquid nitrogen at a temperature lower than -20°C, and grind it with a jet mill to obtain Nafion resin powder with a particle size of 5-10 microns;

[0046] (2) Add sulfonic acid to silica sol with a mass concentration of 12% to adjust the pH value to 6, then add ethanol to dilute to a mass concentration of 5%, and the spray gun pressure of the high-pressure sprayer is 0.5MPa, so that the diluted silica sol can be evenly sprayed on the Nafion resin On the surface of the powder, the spraying amount is controlled to be 8% of the mass of Nafion resin powder, and it is airtight and aged for 2 days;

[0047] (3) The aging material in step (2) is dried by centrifugal spraying, and the hot air at 100°C is sent into the drying chamber in a spiral shape, and the aging material is sent to the centrifugal spray dryer, and the aging material is dispersed into particles after high-speed centrifugal rotation. , and dried by hot air flow to obtain Nafion re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com