LNG (liquefied natural gas) carrier gradient enhancement heat-insulating material and short-process preparation method thereof

A technology for thermal insulation materials and LNG ships, which is applied in the fields of thermal insulation materials and their preparation, gradient-enhanced thermal insulation materials and their short-process preparation fields, can solve problems such as damage to thermal insulation systems, excessive thermal stress of thermal insulation materials, etc. The effect of saving glass fiber and good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

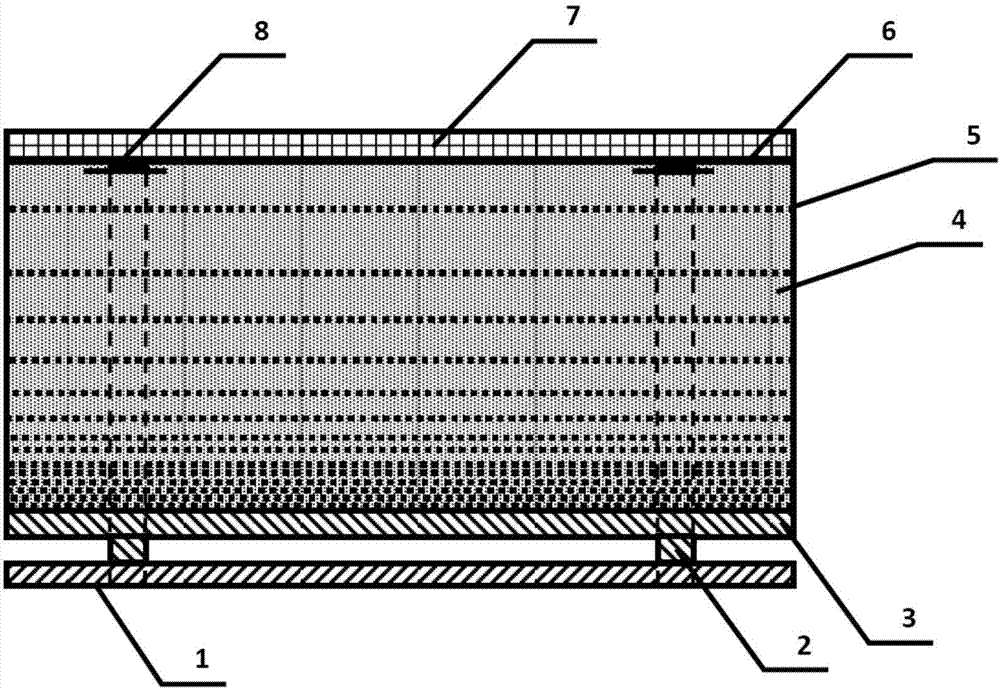

[0042] Selected raw materials: polyether polyol, polymethylene polyphenyl polyisocyanate, tertiary amine catalyst, organotin catalyst, decabromodiphenylethane, antimony trioxide, foam stabilizer, HFC-365mfc, continuous glass fiber mat 5.

[0043] The mass ratio of selected raw materials: 100:150:0.2:0.9:84:21:1.5:40:10.

[0044] Step 1: Dry the polyether polyol, decabromodiphenylethane powder, antimony trioxide powder and continuous glass fiber mat 5 in a forced air drying oven at 90°C for 24 hours, and then cool down to room temperature for use.

[0045] Step 2: Cut the spare continuous glass fiber mat 5 after the treatment in Step 1 into a shape suitable for the mould, and spread it evenly on the bottom of the mould.

[0046] Step 3: Add foam stabilizer, tertiary amine catalyst, organotin catalyst, decabromodiphenylethane, antimony trioxide and HFC-365mfc to polyether polyol and mix, stir evenly, and then quickly add polyol The methylene polyphenyl polyisocyanate is stirre...

Embodiment 2

[0049] Selected raw materials: polyether polyol, polymethylene polyphenyl polyisocyanate, tertiary amine catalyst, organotin catalyst, decabromodiphenylethane, antimony trioxide, foam stabilizer, HFC-365mfc, continuous glass fiber mat 5.

[0050] The mass ratio of selected raw materials: 100:150:0.2:0.9:84:21:1.5:40:20.

[0051] Step 1: Dry the polyether polyol, decabromodiphenylethane powder, antimony trioxide powder and continuous glass fiber mat 5 in a forced air drying oven at 90°C for 24 hours, and then cool down to room temperature for use.

[0052] Step 2: Cut the spare continuous glass fiber mat 5 after the treatment in Step 1 into a shape suitable for the mould, and spread it evenly on the bottom of the mould.

[0053] Step 3: Add foam stabilizer, tertiary amine catalyst, organotin catalyst, decabromodiphenylethane, antimony trioxide and HFC-365mfc to polyether polyol and mix, stir evenly, and then quickly add polyol The methylene polyphenyl polyisocyanate is stirre...

Embodiment 3

[0056] Selected raw materials: polyether polyol, polymethylene polyphenyl polyisocyanate, tertiary amine catalyst, organotin catalyst, decabromodiphenylethane, antimony trioxide, foam stabilizer, HFC-365mfc, continuous glass fiber mat 5.

[0057] The mass ratio of selected raw materials: 100:150:0.2:0.9:84:21:1.5:45:40.

[0058] Step 1: Dry the polyether polyol, decabromodiphenylethane powder, antimony trioxide powder and continuous glass fiber mat 5 in a forced air drying oven at 90°C for 24 hours, and then cool down to room temperature for use.

[0059] Step 2: Cut the spare continuous glass fiber mat 5 after the treatment in Step 1 into a shape suitable for the mould, and spread it evenly on the bottom of the mould.

[0060] Step 3: Add foam stabilizer, tertiary amine catalyst, organotin catalyst, decabromodiphenylethane, antimony trioxide and HFC-365mfc to polyether polyol and mix, stir evenly, and then quickly add polyol The methylene polyphenyl polyisocyanate is stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com