Basic aqueous easily-soluble modified polyesters and preparation method

A modified polyester and copolymer technology, which is applied in the field of modified polyester and its preparation, can solve the problems of poor color, high grayness, and poor spinnability of polyester chips, achieve sufficient alkali water solubility, and improve polymerization The effect of material quality and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

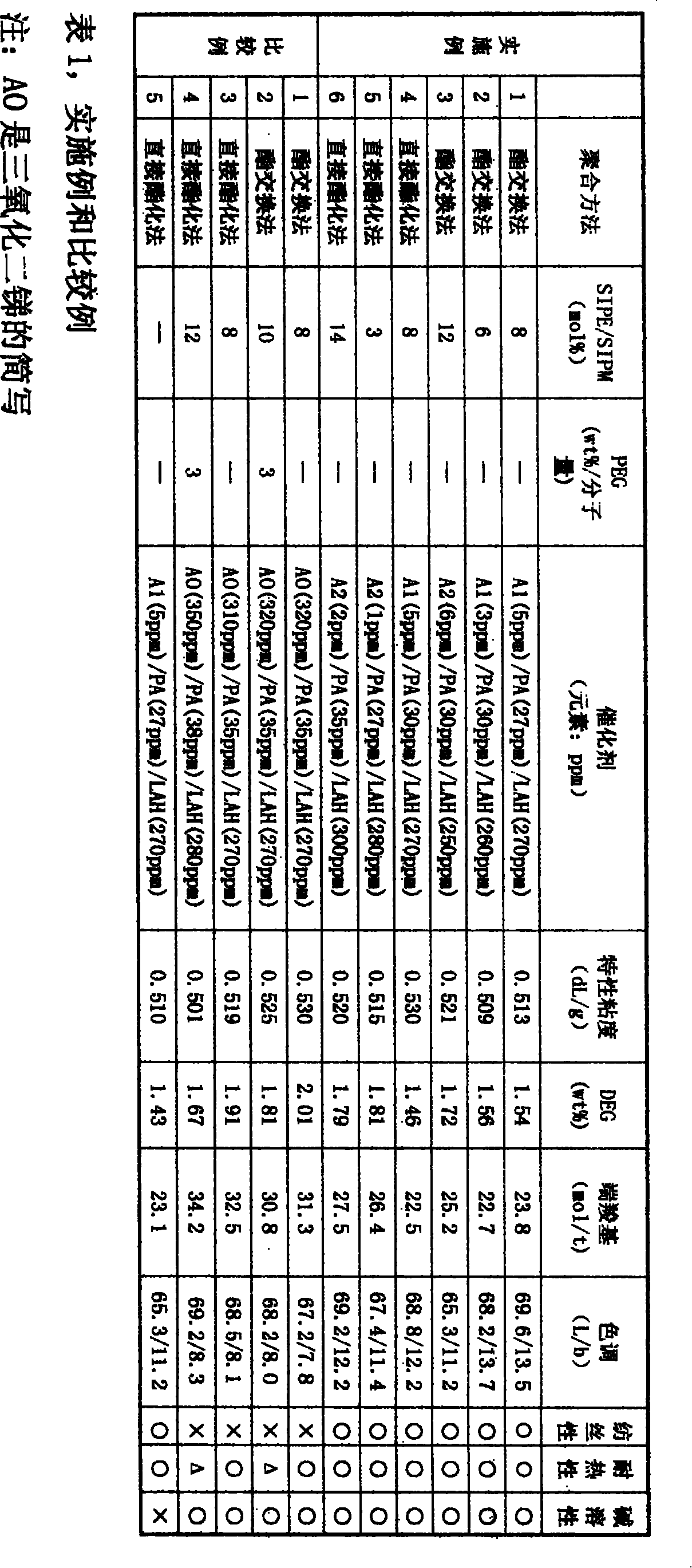

Examples

Embodiment 1

[0032] 100 grams of dimethyl terephthalate and 72 grams of ethylene glycol (molar ratio 1: 1.92) are dropped into the transesterification tank reactor, and 8 mol % (that is, equivalent to 1% in the modified polyester obtained) SIPM (product of Jiangsu Qunfa Co., Ltd.), whose content is 8 mol% in all acid components), 150ppm transesterification catalyst cobalt acetate, under nitrogen atmosphere, heat up to 160~250 DEG C (can be 160 DEG C, 200 DEG C, 200 DEG C, 250°C) for esterification. After the esterification reaction was completed, the esterified product was sent to the polycondensation kettle, and then adding phosphoric acid (PA), 5000ppm lithium acetate (LAH) and titanium compound catalyst A1 with a content of 5 ppm of phosphorus element, phosphoric acid, lithium acetate and titanium compound are both ethylene glycol solutions, and then the temperature is raised from 255°C to 280°C in 1 hour, the pressure is dropped from normal pressure to below 200Pa, and kept in this sta...

Embodiment 4

[0035] Put 100 grams of terephthalic acid and 45 grams of ethylene glycol (molar ratio 1:1.2) into an esterification tank reactor, and carry out esterification reaction at 250° C. After the esterification reaction was completed, the esterified product was sent into the polycondensation kettle, and SIPE (product of Jiangsu Qunfa Co. ), phosphorus element content is 27ppm phosphoric acid, 5000ppm lithium acetate and titanium element content is the titanium compound catalyst A1 of 5ppm, and phosphoric acid, lithium acetate and titanium compound are all ethylene glycol solutions. Then use 1 hour to increase the temperature from 255°C to 280°C, and drop the pressure from normal pressure to below 200Pa, and keep it in this state, and carry out the polymerization reaction for 1 to 3 hours to obtain the modified polyester in Table 1. copolymer. The viscosity of the polymer is 0.53, the content of diethylene glycol is 1.46wt%, the content of terminal carboxyl groups is 22.5 mol / t, and...

Embodiment 7

[0060] A method for preparing modified polyester easily soluble in alkaline water, including esterification and polymerization, in which dimethyl terephthalate, terephthalic acid, and ethylene glycol are used as the first and second components, and metal-containing Sulfonate-based isophthalic acid is the third component; titanate is used as a catalyst, a phosphorus compound is used as a stabilizer, and an alkali metal compound is used as an additive.

[0061] The general chemical formula of isophthalic acid containing metal sulfonate groups is shown below:

[0062] Formula 1)

[0063] where R 1 and R 2 Hydrogen (or methyl or hydroxyethyl), respectively, M is lithium metal (or sodium or potassium).

[0064] The content of the isophthalic acid component containing sulfonate group in the total acid is 2.0-15.0 mole % (that is, the content equivalent to the content of 2.0-15.0 mole % in the total acid component in the prepared modified polyester) ( Example 2.0%, 9%, 15%).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com