High-quality enzymolysis-fermented bean pulp as well as preparation method and application thereof

A fermented soybean meal, high-quality technology, applied in application, food processing, animal feed, etc., can solve the problems of incomplete treatment of anti-nutritional factors, inability to effectively replace fish meal, unstable resource supply, etc. Improves digestibility and palatability, and resolves nutritional diarrhea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

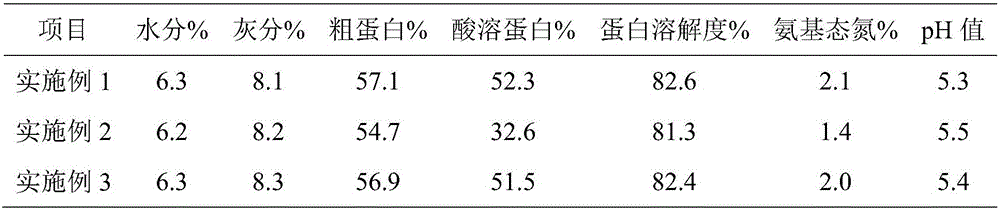

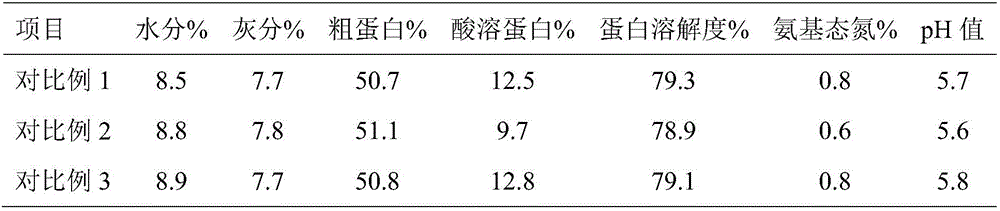

Embodiment 1

[0062] A method for preparing high-quality enzymatically fermented soybean meal, comprising the following steps:

[0063] 1) Pulverize 1000kg of peeled soybean meal, pass through an 80-mesh sieve, add water 3-4 times the weight of soybean meal, and stir evenly;

[0064] 2) Add α-galactosidase with a weight of 0.5‰ of soybean meal and glucoamylase with a weight of 1‰ of soybean meal to the material obtained in step 1), and carry out enzymatic hydrolysis for 2-3 hours; then add papain with a weight of 0.3‰ of soybean meal to carry out Enzyme hydrolysis for 2-3 hours; after the enzymolysis is complete, immediately raise the temperature to 85-90°C, and inactivate the enzyme for 30 minutes;

[0065] Among them, the enzymatic hydrolysis condition is pH 6.0, and the enzymatic hydrolysis temperature is 50-55°C; the enzyme activities of α-galactosidase, glucoamylase, and papain are 3000IU / g, 200,000IU / g, and 800,000IU / g, respectively. ;

[0066] 3) Lower the temperature of the materi...

Embodiment 2

[0069] A method for preparing high-quality enzymatically fermented soybean meal, comprising the following steps:

[0070] 1) Pulverize 1000kg of peeled soybean meal, pass through an 80-mesh sieve, add water 3-4 times the weight of soybean meal, and stir evenly;

[0071] 2) Add α-galactosidase with a weight of 0.3‰ of soybean meal and glucoamylase with a weight of 1‰ of soybean meal to the material obtained in step 1), and carry out enzymatic hydrolysis for 1.5-2 hours; then add papain with a weight of 0.2‰ of soybean meal to carry out Enzyme hydrolysis for 1.5-2 hours; after the enzymolysis is complete, immediately raise the temperature to 85-90°C, and inactivate the enzyme for 30 minutes;

[0072] Among them, the enzymatic hydrolysis condition is pH 6.0, and the enzymatic hydrolysis temperature is 50-55°C; the enzyme activities of α-galactosidase, glucoamylase, and papain are 3000IU / g, 200,000IU / g, and 800,000IU / g, respectively. ;

[0073] 3) Cool the material obtained in s...

Embodiment 3

[0076] A method for preparing high-quality enzymatically fermented soybean meal, comprising the following steps:

[0077] 1) Pulverize 1000kg of peeled soybean meal, pass through an 80-mesh sieve, add water 3-4 times the weight of soybean meal, and stir evenly;

[0078] 2) Add α-galactosidase with a weight of 0.5‰ of soybean meal and glucoamylase with a weight of 1‰ of soybean meal to the material obtained in step 1), and carry out enzymatic hydrolysis for 1.5-2 hours; then add papain with a weight of 1.0‰ of soybean meal to carry out Enzyme hydrolysis for 1.5-2 hours; after the enzymolysis is complete, immediately raise the temperature to 85-90°C, and inactivate the enzyme for 30 minutes;

[0079] Among them, the enzymatic hydrolysis condition is pH 6.0, and the enzymatic hydrolysis temperature is 50-55°C; the enzyme activities of α-galactosidase, glucoamylase, and papain are 3000IU / g, 200,000IU / g, and 800,000IU / g, respectively. ;

[0080] 3) Cool the material obtained in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com