Beneficiation method for refractory iron ores

A beneficiation method and iron ore technology, which is applied in the beneficiation field of refractory iron ore, can solve problems such as inability to mine and utilize resources, difficult beneficiation, and inability to realize separation, etc., and achieve the effect of good economy and stable product indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

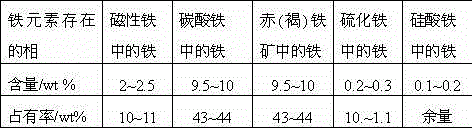

Problems solved by technology

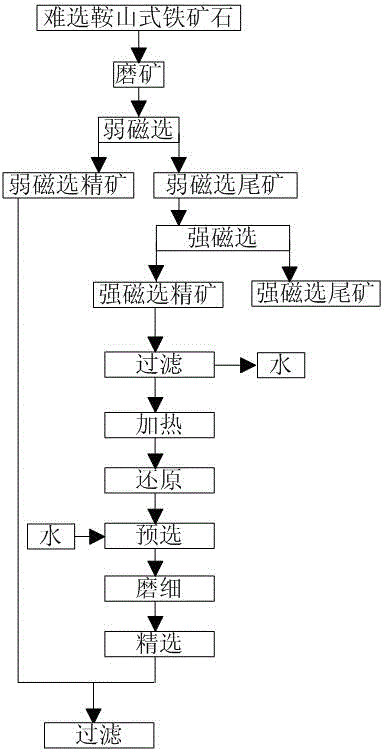

Method used

Image

Examples

Embodiment 1

[0032] The refractory Anshan-type iron ore is crushed to a particle size of 2~15mm, put into a closed-circuit grinding system composed of a ball mill and a cyclone for grinding treatment, and the part of the graded overflow product with a particle size of -0.074mm accounts for the refractory Anshan 60% of the total weight of the type iron ore; the iron grade of the refractory Anshan type iron ore is 30%;

[0033] The graded overflow products are subjected to weak magnetic separation through a weak magnetic separator to obtain a weak magnetic separation concentrate and a weak magnetic separation tailings. The iron grade of the weak magnetic separation concentrate is 68%, accounting for 12% of the total weight of the refractory Anshan type iron ore. %; The weak magnetic separation tailings are subjected to strong magnetic separation through a strong magnetic separator to obtain strong magnetic separation concentrates and strong magnetic separation tailings; the iron grade of stro...

Embodiment 2

[0038] Method is with embodiment 1, and difference is:

[0039] (1) The fraction of particle size -0.074mm in the classified overflow product accounts for 70% of the total weight of the refractory Anshan iron ore; the iron grade of the refractory Anshan iron ore is 28%;

[0040] (2) The iron grade of the weak magnetic separation concentrate is 67%, accounting for 15% of the total weight of the refractory Anshan iron ore; the iron grade of the strong magnetic separation concentrate is 28%; the magnetic field strength during the weak magnetic separation is 0.2T, The magnetic field strength during strong magnetic separation is 1.2T;

[0041] (3) Filter the strong magnetic separation concentrate to obtain a filter cake with a water weight of 15%, then heat it to 680°C for 30s to remove moisture, and place it in a reducing atmosphere for 10 minutes; the iron grade of the coarse magnetite is 32%; The reducing atmosphere is a hydrogen atmosphere;

[0042] (4) Add water to the rough...

Embodiment 3

[0045] Method is with embodiment 1, and difference is:

[0046] (1) The fraction of particle size -0.074mm in the classified overflow product accounts for 75% of the total weight of the refractory Anshan iron ore; the iron grade of the refractory Anshan iron ore is 25%;

[0047] (2) The iron grade of the weak magnetic separation concentrate is 67%, accounting for 19% of the total weight of the refractory Anshan iron ore; the iron grade of the strong magnetic separation concentrate is 25%; the magnetic field strength during the weak magnetic separation is 0.2T, The magnetic field strength during strong magnetic separation is 1.0T;

[0048] (3) Filter the concentrated ore by strong magnetic separation to obtain a filter cake with a water weight of 20%, then heat it to 650°C for 60 seconds to remove moisture, and place it in a reducing atmosphere for 20 minutes; the iron grade of the coarse magnetite is 30%; The reducing atmosphere is gas atmosphere;

[0049](4) Add water to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com