Preparation method of pharmaceutical grade ferric trichloride product

A ferric chloride, pharmaceutical-grade technology, applied in ferric halide and other directions, can solve the problems of meager profits, low output and high production costs, and achieve the effects of economical and easy-to-obtain raw materials, simple operation and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

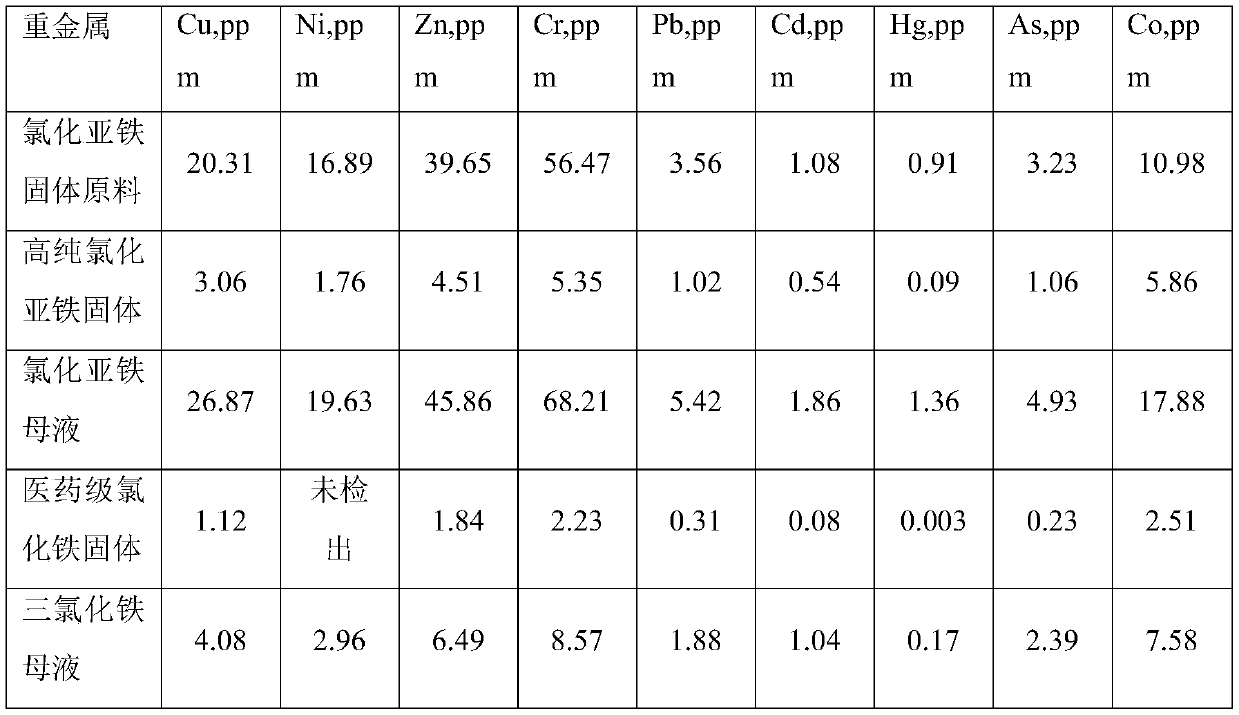

Embodiment 1

[0024] 1. Take 2kg of ferrous chloride solid, dissolve it in an appropriate amount of water, properly heat until the solid is dissolved, and add 200g of synthetic industrial hydrochloric acid to prevent the hydrolysis of ferrous and heavy metals;

[0025] 2. The ferrous chloride solution passes through a filter to remove the insoluble matter in the solution. The mass concentration of ferrous chloride is 38-45%, and it is naturally cooled to 10-20°C. The upper mother liquor is pumped away, the lower crystals are centrifuged at 800 r / min by a centrifuge until no mother liquor remains, the ferrous chloride crystals are washed with 5% hydrochloric acid solution and then centrifuged to obtain high-purity ferrous chloride solids.

[0026] 3. Dissolve the high-purity ferrous chloride solid in a proper amount of 1% hydrochloric acid solution, oxidize with chlorine to 0.005~0.01% ferrous, and then add a small amount of sodium chlorate solution to oxidize ferrous to reach pharmaceutical grade...

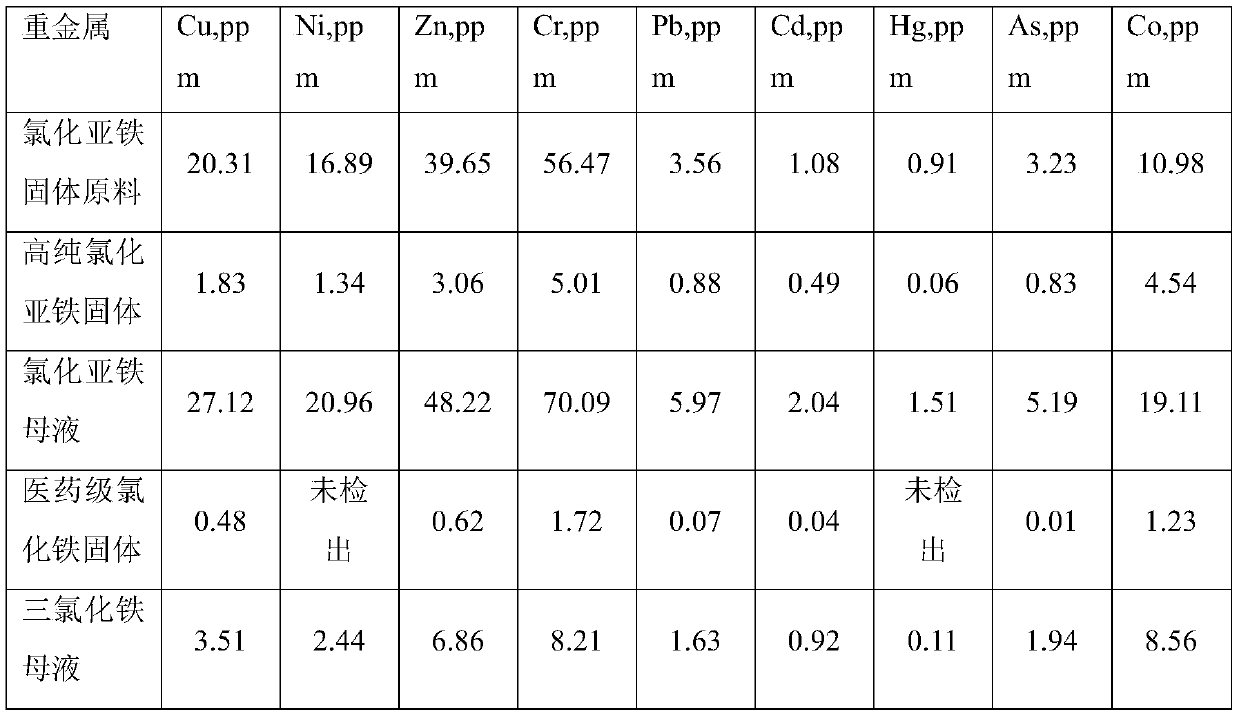

Embodiment 2

[0032] 1. Take 2kg of ferrous chloride solid, dissolve it in an appropriate amount of water, properly heat until the solid is dissolved, and add 200g of synthetic industrial hydrochloric acid to prevent the hydrolysis of ferrous and heavy metals;

[0033] 2. The ferrous chloride solution is passed through a filter to remove the insoluble matter in the solution, concentrated by evaporation to a mass concentration of ferrous chloride of 38-45%, and naturally cooled to 10-20°C. The upper mother liquor is pumped away, the lower crystals are centrifuged at 2000 r / min until no mother liquor remains, and the ferrous chloride crystals are washed with 10% hydrochloric acid solution and then centrifuged to obtain high-purity ferrous chloride solids.

[0034] 3. Dissolve the high-purity ferrous chloride solid in a proper amount of 1% hydrochloric acid solution, oxidize with chlorine to 0.005~0.01% ferrous, and then add a small amount of sodium chlorate solution to oxidize ferrous to reach phar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com