Process for separating copper from waste micro/fine-particle zinc tailing

A technology for fine particles and tailings, which can be used in flotation, solid separation, etc., and can solve problems such as waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

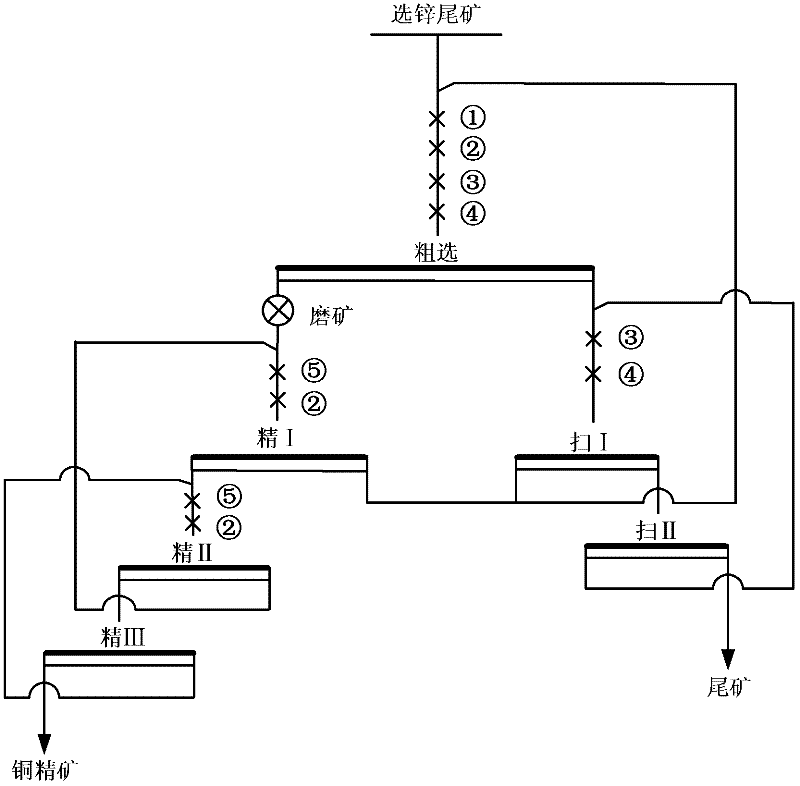

Image

Examples

Embodiment 1

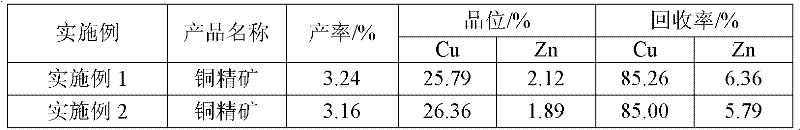

[0017] Example 1: According to the dry weight of zinc tailings per ton, add 4kg / t of industrial lime to the zinc-selected tailings to adjust the pH value to about 10, and add 2.0kg / t of zinc sulfate+2.0kg / t of sodium sulfite at the same time, and stir 3 minutes, then add 100g / t of butyl xanthate + 50g / t of ethiazide + 100g / t of Z-200 and 25g / t of foaming agent pinitol oil at the same time, stir for 2 minutes, and carry out flotation Selection; at the same time, add butyl xanthate dosage 50g / t+ ethylthiazide dosage 25g / t+Z-200 dosage 50g / t and foaming agent terpineol oil dosage 15g / t, stir for 2 minutes, and carry out the first sweeping ; Do not add any chemicals in the second sweeping; use a ball mill to finely grind the rough concentrate to a fineness of -0.02mm 80%, add new water to adjust the slurry to a pulp concentration of 10%, add water glass in an amount of 1kg / t, and stir For 2 minutes, add 1 kg / t of zinc sulfate + 1 kg / t of sodium sulfite at the same time, stir for 2...

Embodiment 2

[0018] Embodiment 2: Embodiment 2 (optimum condition medicament dosage upper limit) has only individual process parameter and medicament dosage different from embodiment 1 (optimum condition medicament dosage lower limit), and other conditions are substantially the same as both of the implementation process. According to the dry weight of each ton of zinc tailings, add 4.5kg / t of industrial lime to the zinc-selected tailings to adjust the pH value to about 11. At the same time, add 2.5kg / t of zinc sulfate + 2.5kg / t of sodium sulfite, and stir for 3 minutes. Then add butyl xanthate dosage 120g / t+ ethiazide dosage 60g / t+Z-200 dosage 120g / t and foaming agent terpineol oil dosage 30g / t simultaneously, stir 2 minutes, carry out flotation rough selection; Add 60g / t of butyl xanthate + 30g / t of ethionate + 60g / t of Z-200 and 15g / t of foaming agent terpineol oil, stir for 2 minutes, and perform the first sweep; Do not add any chemical agent for the second sweeping; use a ball mill to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com