Beneficiation method for high carbonate iron ore

A beneficiation method and carbonate technology, which are applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of high production cost and low resource utilization rate, and achieve the effect of stable product index and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

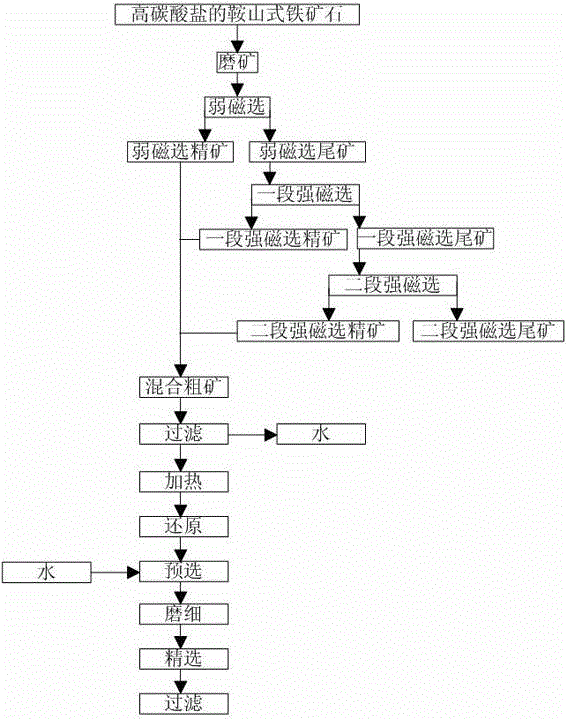

Method used

Image

Examples

Embodiment 1

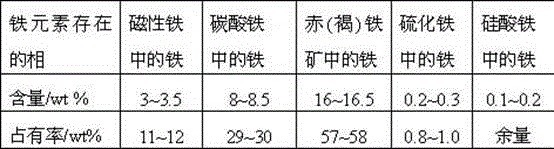

[0030] The Anshan-type iron ore with high carbonate is crushed to a particle size of 2~15mm, put into a closed-circuit grinding system composed of a ball mill and a cyclone for grinding treatment, and the fraction of the particle size -0.074mm in the classified overflow product is obtained. 60% of the total weight of the Anshan type iron ore of high carbonate; the iron grade of the Anshan type iron ore of the high carbonate is 30%, wherein the weight content of carbonate is 30%;

[0031] The graded overflow product is subjected to weak magnetic separation through a weak magnetic separator to obtain weak magnetic separation concentrate and weak magnetic separation tailings, and the weak magnetic separation tailings are subjected to a high-level magnetic separation through a high-level magnetic separator to obtain a high-level magnetic separation Concentrate ore and tailings of the first stage of strong magnetic separation, the tailings of the first stage of strong magnetic separ...

Embodiment 2

[0036] Method is with embodiment 1, and difference is:

[0037] (1) The iron grade of Anshan type iron ore with high carbonate is 28%, and the weight content of carbonate is 35%; 70% of the total weight of type iron ore;

[0038] (2) The iron grade of the mixed coarse ore is 52%; the magnetic field strength for weak magnetic separation is 0.3T, and the magnetic field strength for the first-stage strong magnetic separation and the second-stage strong magnetic separation is 1.2T;

[0039] (3) Filter the mixed coarse ore to obtain a filter cake with a water weight of 15%, then heat it to 680°C for 30s, place it in a reducing atmosphere for 10 minutes, and then air cool it to below 50°C; the iron grade of the magnetite coarse ore is at 55%; the reducing atmosphere is a hydrogen atmosphere;

[0040] (4) Add water to the coarse magnetite ore to make a slurry with a weight concentration of 40%, stir for 35 minutes, and pre-select to control the magnetic field strength to 0.25T; the...

Embodiment 3

[0043] Method is with embodiment 1, and difference is:

[0044] (1) The iron grade of Anshan type iron ore with high carbonate is 25%, and the weight content of carbonate is 45%; 75% of the total weight of type iron ore;

[0045] (2) The iron grade of the mixed coarse ore is 47%; the magnetic field strength is 0.2T for weak magnetic separation, and 1.2T for the first stage of strong magnetic separation and the second stage of strong magnetic separation;

[0046] (3) Filter the mixed coarse ore to obtain a filter cake with a water weight of 15%, then heat it to 650°C for 60 seconds, place it in a reducing atmosphere for 15 minutes, and then air-cool it to below 50°C; the iron grade of the magnetite coarse ore is at 50%; reducing atmosphere is gas atmosphere;

[0047](4) Add water to the rough magnet ore to make a slurry with a weight concentration of 35%, stir for 30 minutes, and pre-select the control magnetic field strength to 0.2T; the iron grade of the rough concentrate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com