Camera module and bracket thereof

A technology of camera modules and bumps, which is applied in image communication, TV, color TV parts, etc., and can solve problems such as less glue, inability to firmly connect the voice coil motor and the bracket, and glue flowing to the outer wall of the bracket, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The camera module and its support will be further described below in conjunction with the accompanying drawings and specific embodiments.

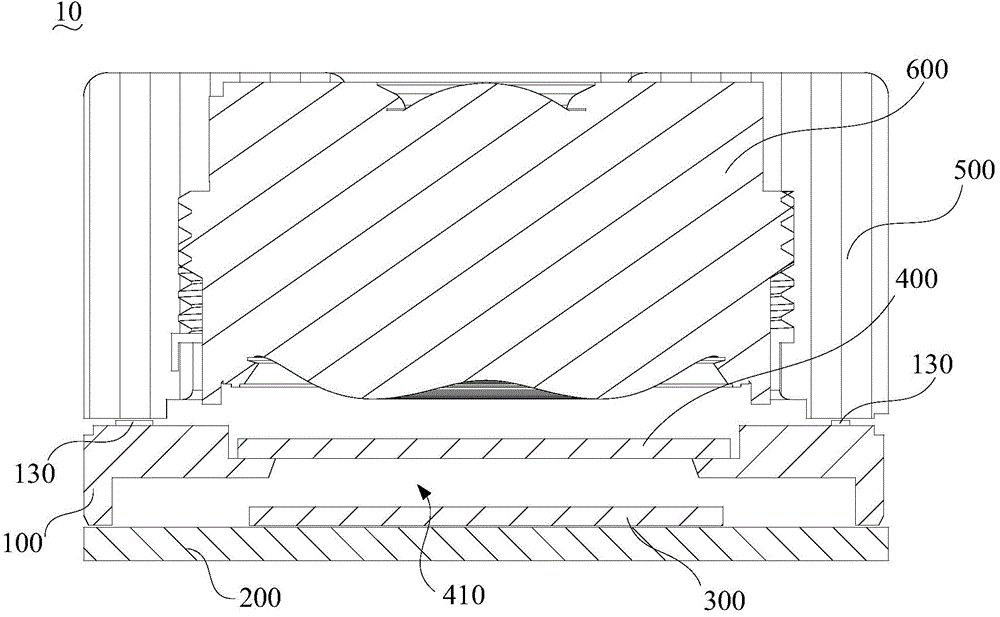

[0038] Such as figure 1 As shown, the camera module 10 of an embodiment includes a bracket 100 , a circuit board 200 , an image sensor chip 300 , an infrared cut filter 400 , a voice coil motor 500 and a lens 600 .

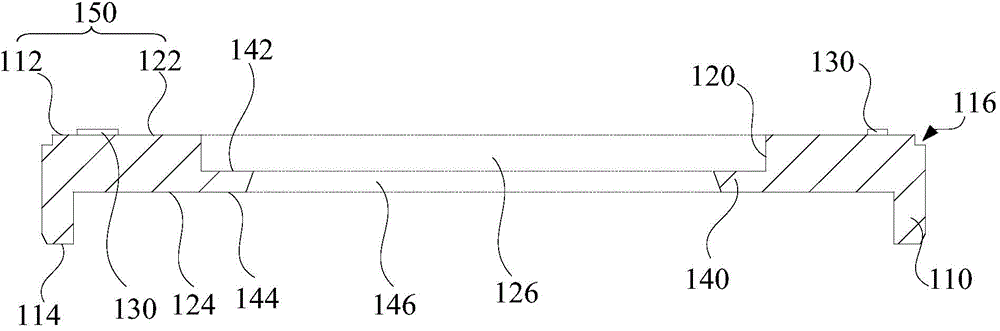

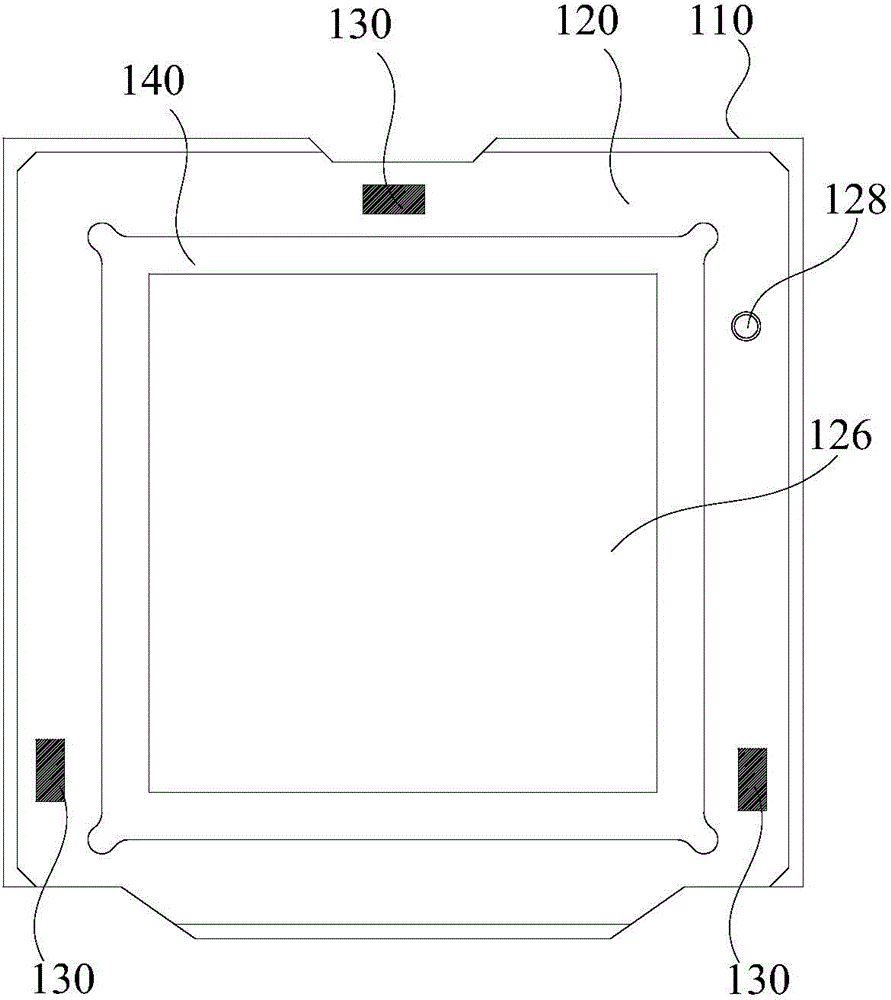

[0039] Such as figure 2 and image 3 As shown, the bracket 100 includes a cylinder body 110 , a mounting plate 120 , a bump 130 and a bearing plate 140 .

[0040] The barrel 100 has a first end surface 112 and a second end surface 114 opposite to each other. In this embodiment, the barrel 100 is square. In other embodiments, the barrel 100 may also be cylindrical.

[0041] The mounting board 120 has a first surface 122 and a second surface 124 opposite to each other. The installation plate 120 is disposed in the cylinder body 110 , and the first surface 122 is flush with the first end surface 112 and constitutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com