Novel liquid distribution system

A distribution system and liquid technology, applied in the field of new liquid distribution system, can solve problems such as deviation, uneven distribution, liquid cannot flow to the liquid storage tank, etc., and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

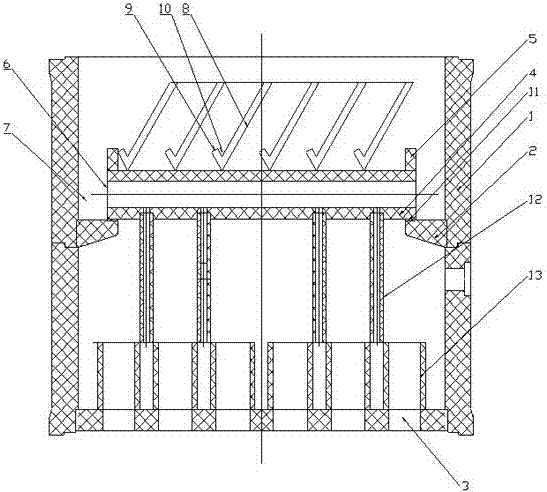

[0023] like figure 1 A novel liquid dispensing system is shown, consisting of

[0024] A cylinder 1, the cylinder 1 is a vessel-like structure with an open upper end and a closed lower end, an annular support protrusion 2 is arranged in the middle of the inner wall of the cylinder 1, and several distributions are evenly distributed on the bottom surface of the cylinder 1. Hole 3.

[0025] A liquid collection unit arranged on the upper part of the cylinder body 1 includes a liquid collection tank, the liquid collection tank is composed of a circular bottom plate 4 supported on the support protrusion 2 and an annular ring connected to the outer edge of the bottom plate 4 and extending upward. The plates 5 are formed together, and at the same time, there is an overflow hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com