Fabric laminating machine using PU glue

A laminating machine and fabric technology, applied in lamination device, lamination auxiliary operation, lamination and other directions, can solve the problems of uneven fabric, easy degumming of fabric, wrinkle of fabric, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

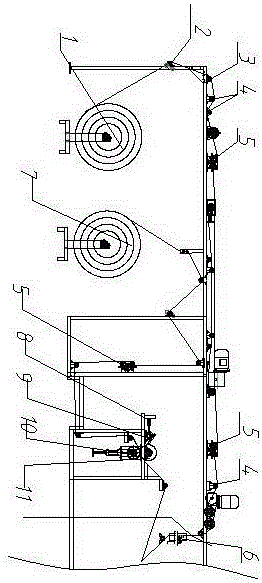

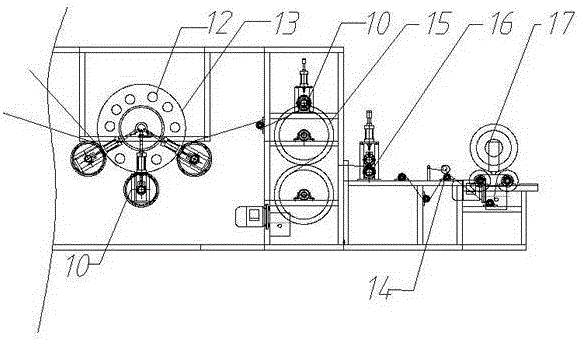

[0015] like figure 1 The shown fabric compounding machine using PU glue includes a frame on which a fabric unwinding mechanism, a bottom material unwinding mechanism, a gluing mechanism, a heat pressing mechanism, a traction mechanism and a retracting mechanism are arranged. volume mechanism.

[0016] The fabric unwinding mechanism includes a fabric unwinding device 7, and the fabric unwinding device 7 carries out the process on the fabric through the stretcher 2, the cloth guide roller 3, the winding wire opening roller 4, the pneumatic deviation correction device 5 and the edge stripper 6. After pretreatment, it is sent to the heat pressing mechanism for heat pressing.

[0017] The bottom material unwinding mechanism is sent to the gluing mechanism through the stretcher 2, the cloth guide roller 3, the winding opening roller 4, and the pneumatic deviation correction device 5 for gluing, and then sent to the heat pressing mechanism for heat pressing .

[0018] The gluing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com