Bottle cap assembling device and assembling method

A technology for assembling devices and bottle caps, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve the problem that the bottle cap assembly cannot be effectively fixed, the scope of application of the bottle cap assembly machine is narrow, and the cap body of the bottle cap assembly is damaged, etc. problems, to achieve the effect of improving work stability, reducing debugging difficulty, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

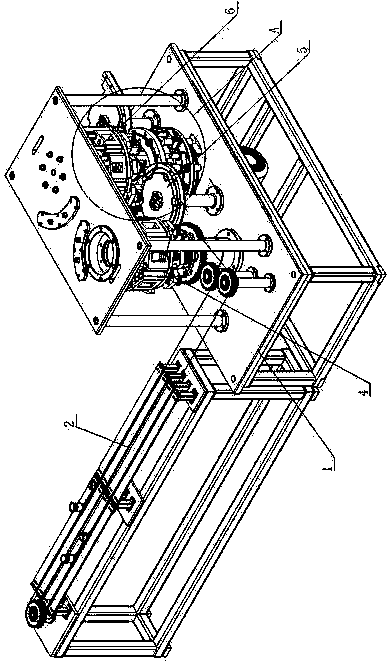

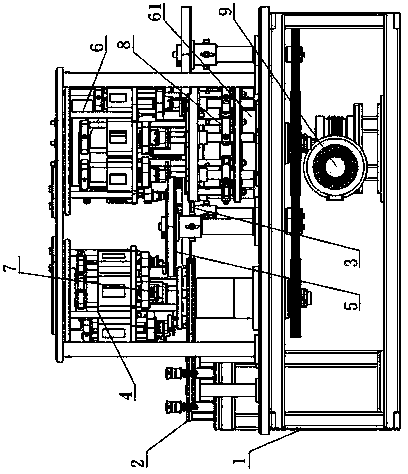

[0068] like figure 1 , figure 2 and image 3 As shown, the bottle cap assembly device includes a frame 1, an outer cap feeding mechanism 2, an inner cap feeding mechanism 3, an auxiliary turret 4, a transfer dial 5 and a pressing turret 6;

[0069] Auxiliary turret 4, transfer dial 5 and pressing turret 6 are rotatably arranged on frame 1, auxiliary turret 4 is provided with suction device 7, and pressing turret 6 is provided with suction device 7 and jacking device 8 , the jacking device 8 is located directly below the suction device 7;

[0070] The outer cover feeding mechanism 2 is arranged on the frame 1 and transports the outer cover to the auxiliary turret 4 so that the outer cover is sucked by the suction device 7 on the auxiliary turret 4;

[0071] The auxiliary turret 4 rotates to transport the outer cover sucked by the suction device 7 to the transfer dial 5;

[0072] The transfer dial 5 is set between the auxiliary turret 4 and the pressing turret 6 and transpo...

Embodiment 2

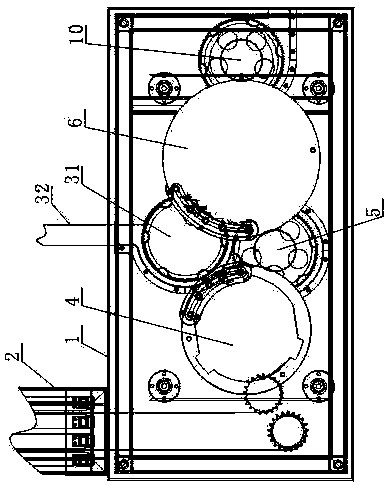

[0083] like Figure 4 As shown, this embodiment further describes the suction device on the basis of Embodiment 1. The suction device 7 includes a suction nozzle 71, a fixed block 72, a connecting body 73 and a lifting structure, and a plurality of fixed blocks 72 are arranged on the circumference Evenly arranged on the auxiliary turret 4 and the pressing turret 6 in the direction, the connecting body 73 runs through the fixed block 72, the bottom end of the connecting body 73 is connected with the suction nozzle 71, and the upper end of the connecting body 73 is connected with the lifting structure.

[0084] In this embodiment, the lifting structure drives the suction nozzle 71 to move up and down. When pressing, the outer cover can be moved downward to realize the relative movement between the inner cover and the outer cover, so that the outer cover and the inner cover can be pressed more efficiently. close; when sucking the outer cover, the suction nozzle 71 can be made clo...

Embodiment 3

[0087] like Figure 4 , Figure 5 and 6 In this embodiment, on the basis of embodiment 2, the lifting structure is specifically described. The lifting structure includes a runner 74 and a cylinder 75, the cylinder 75 is fixed on the top of the frame 1, and the outer circumference of the cylinder 75 is provided with an annular chute 76, the annular chute 76 includes interconnected high sections 77 and the low section 78, the height of the high section 77 is greater than the height of the low section 78, the runner 74 is arranged on the upper end of the connecting body 73, and the runner 74 is arranged in the annular chute 76.

[0088]On the auxiliary turret 4, when the suction device 7 passes above the cover feeding mechanism 2, the runner 74 moves from the high section 77 to the low section 78 to make the air nozzle 71 close to the cover to suck up the cover. On the pressing turret 6, when the suction device 7 picks up the outer cover and moves to the top of the inner cover,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com