High-precision flat plate-type brake test bench

A flat-plate braking and high-precision technology, which is applied in the testing of machine/structural components, vehicle testing, instruments, etc., can solve the problems of insufficient braking force detection accuracy, improve test accuracy, test results are accurate, eliminate height difference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0051] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

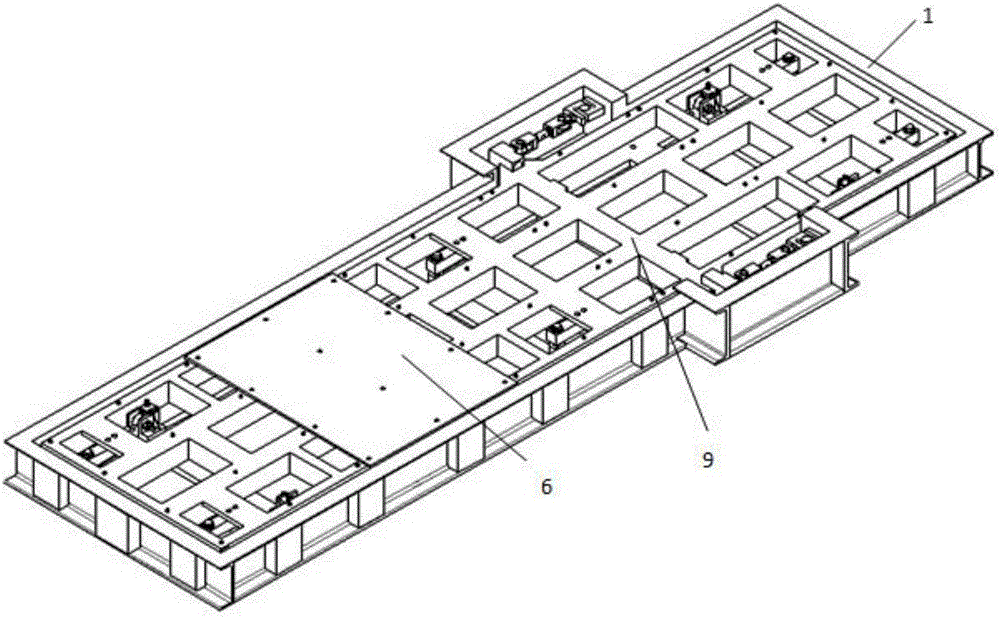

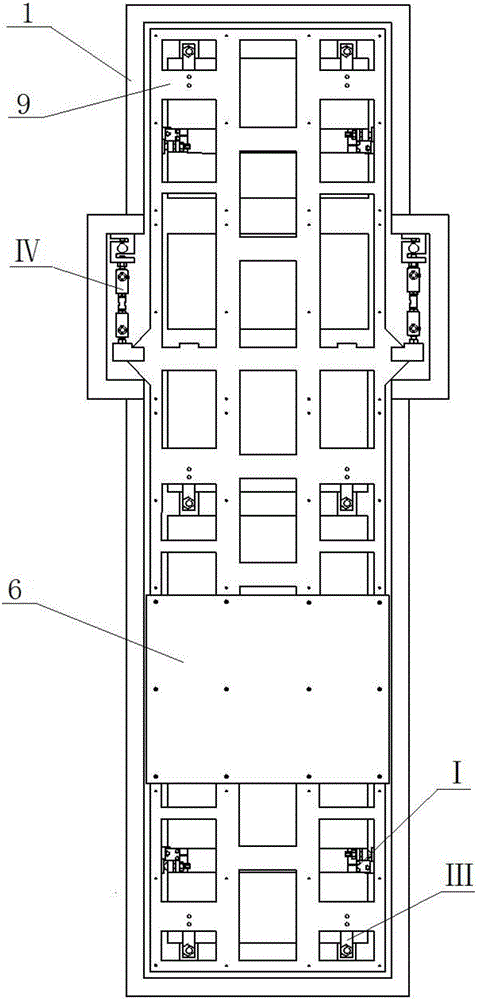

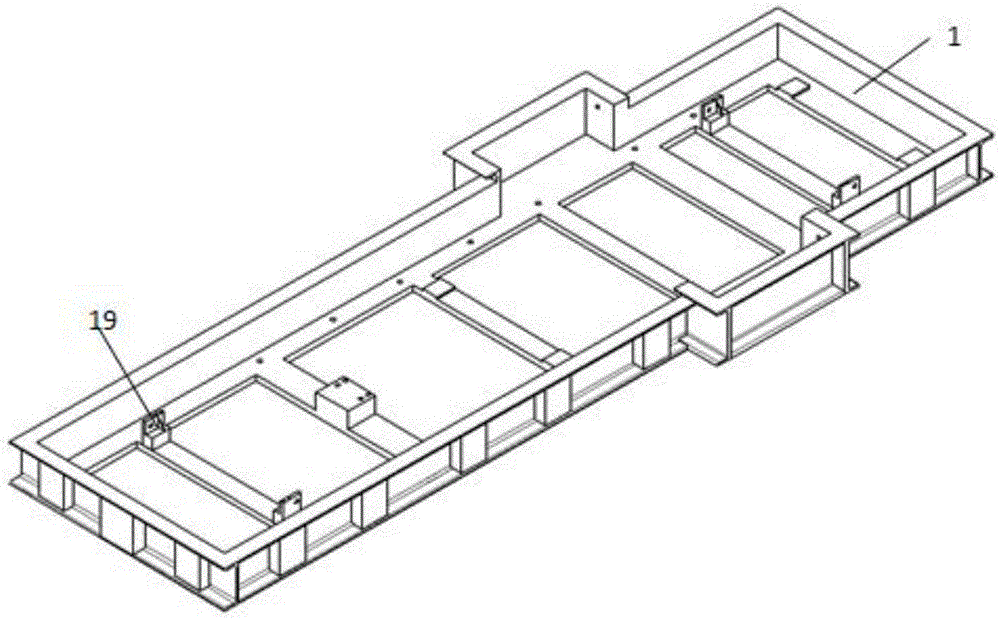

[0052] like figure 1 and figure 2 As shown, the present invention provides a high-precision plate-type brake inspection platform, which is mainly composed of a support frame 1, a brake platen 6, a load-bearing frame 9, a braking force detection mechanism IV, a wheel weight detection mechanism III, and a guide limit mechanism I Composition.

[0053] The two sides of the support frame 1 are symmetrically provided with two grooves, and the notches of the grooves face inward, so that the support frame 1 as a whole has a "middle" symmetrical structure. The load-bearing frame 9 is installed inside the support frame 1; the braking platen 6 is installed above the load-bearing frame 9 through bolts; two sets of braking force detection mechanisms IV are symmetrically installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com