System and method for improving uniformity of selective catalytic reduction (SCR) flow field

A technology of uniformity and flow field, which is applied in the system field of improving the uniformity of SCR flow field, can solve the problems of uneven flow field in the flue, and the inability to adjust the flow field in the flue, so as to reduce the area of flue gas flow, reduce blockage, Effect of reducing flue gas velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

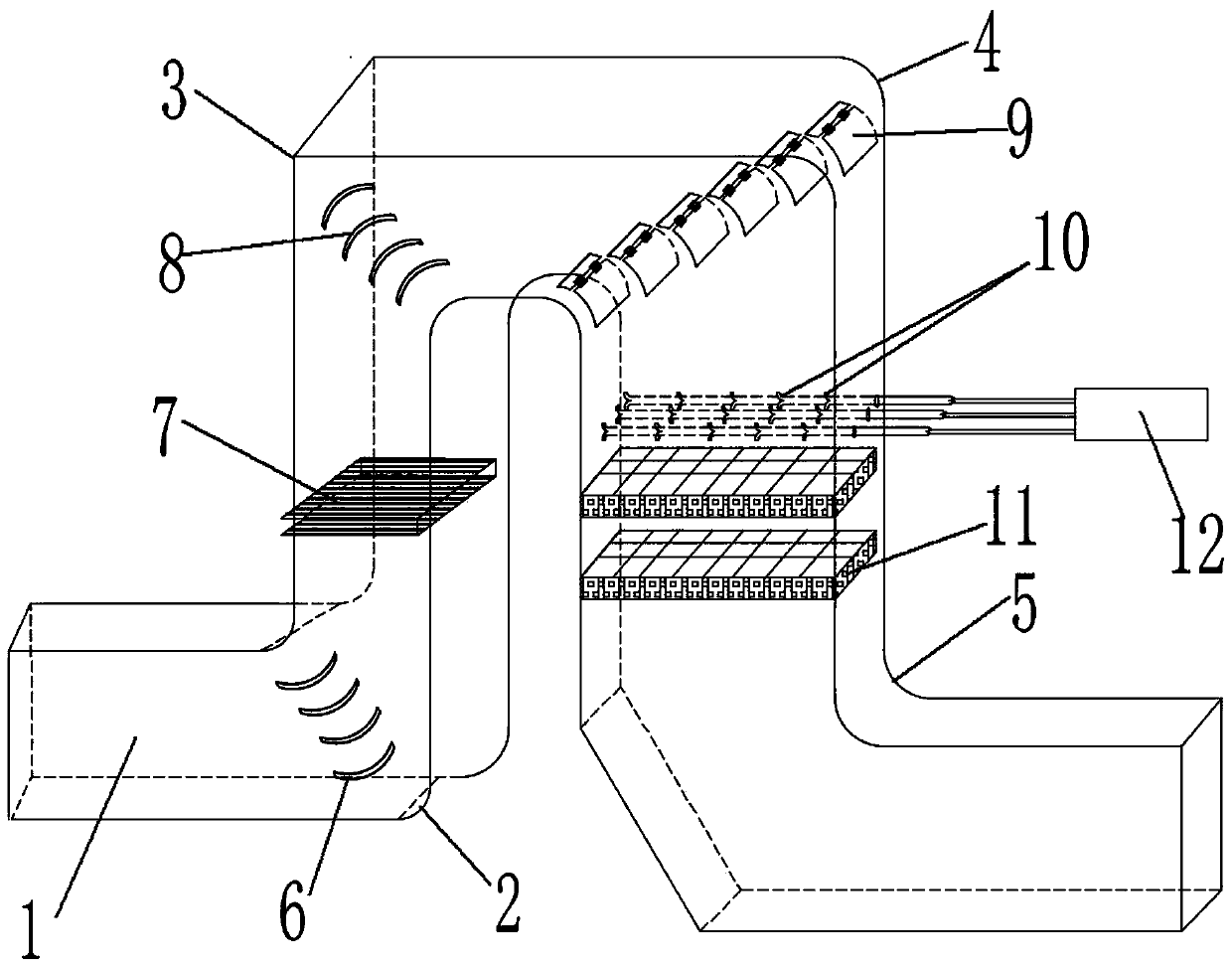

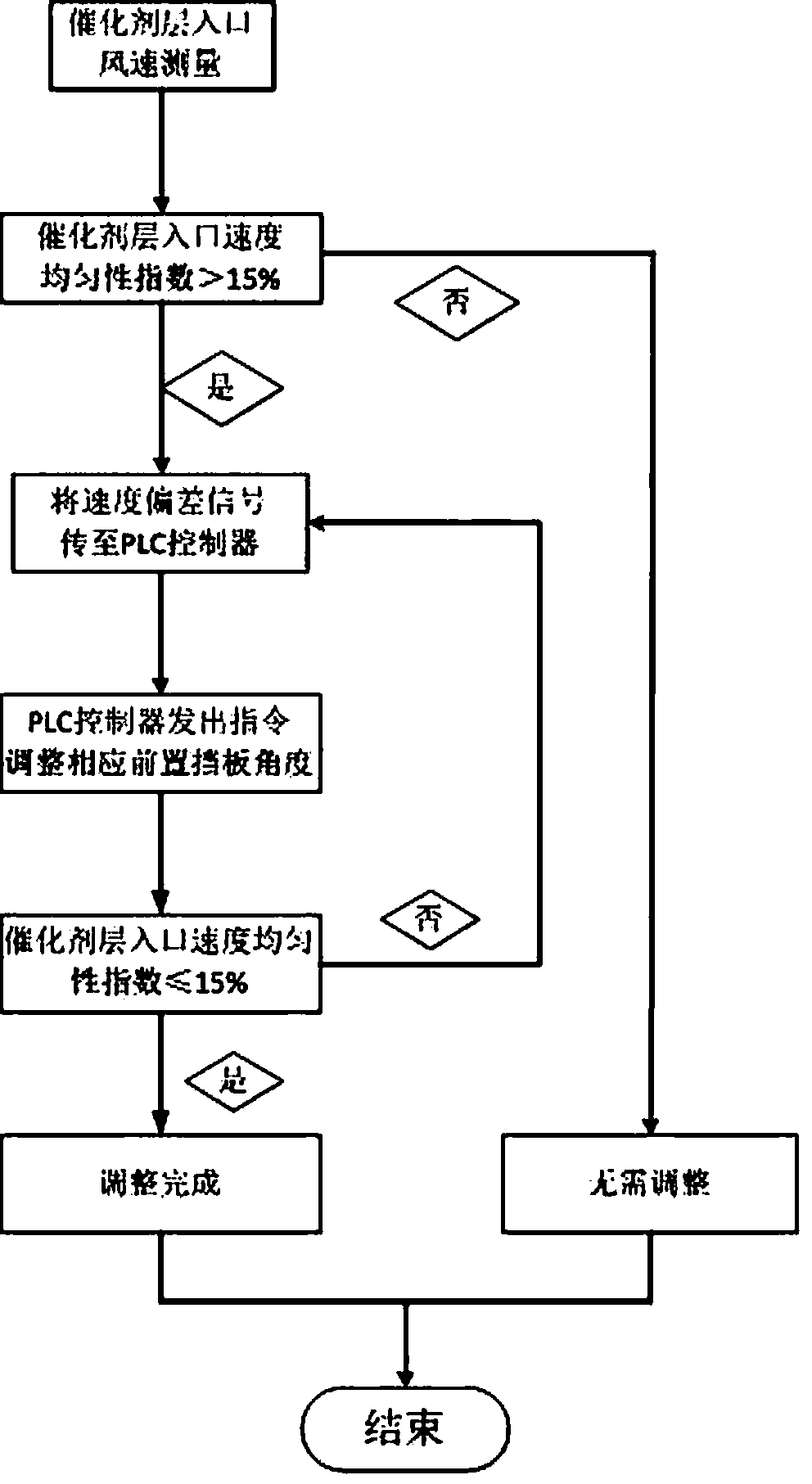

[0038] Attached below figure 1 , attached figure 2 , attached image 3 The present invention will be further described.

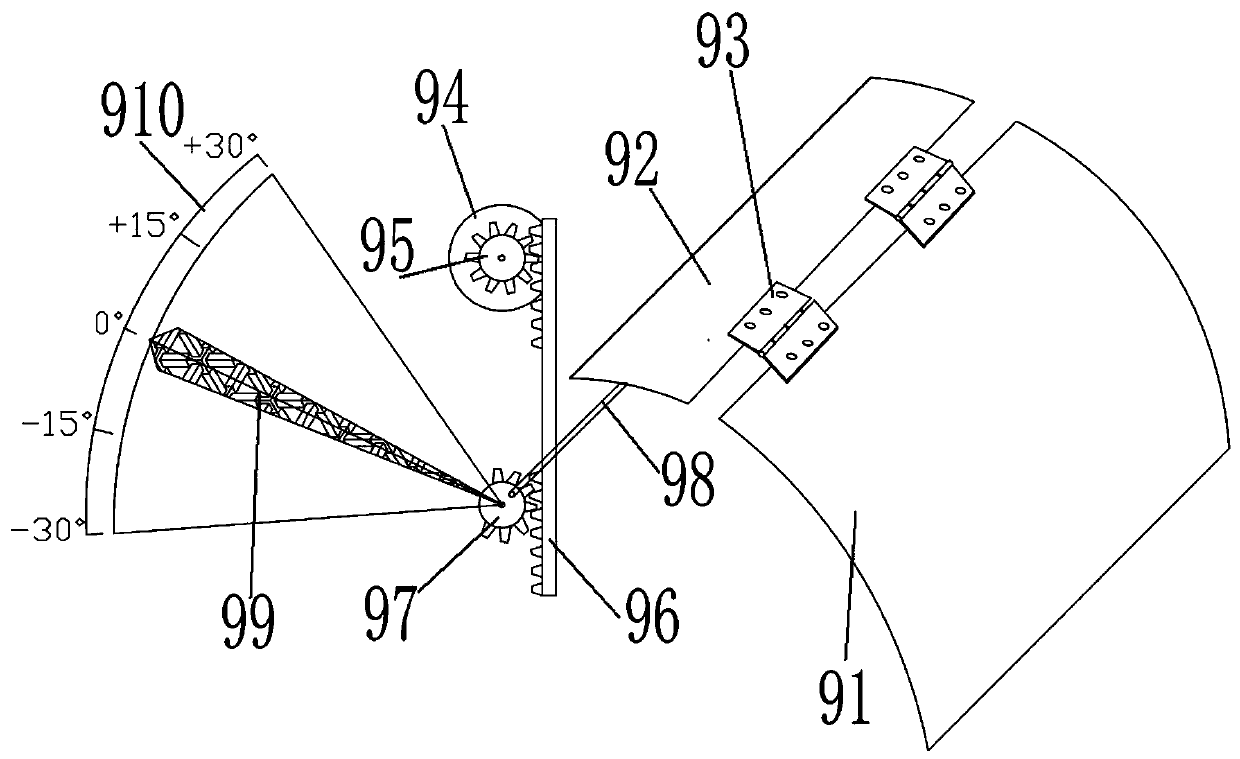

[0039]A system for improving the uniformity of the SCR flow field, comprising: a flue 1, which has a π-shaped structure, the lower end of the front of the flue 1 is the first corner 2, the upper end of the front is the second corner 3, and the upper end of the rear is the third corner 4. The lower end behind it is the fourth corner 5; a number of arc-shaped primary deflectors 6 are evenly spaced along the diagonal direction of the first corner 2; several arc-shaped secondary deflectors 8, It is arranged at even intervals along the diagonal direction of the second corner 3; the ammonia injection grill 7 is arranged between the first corner 2 and the second corner 3; N three-stage deflectors 9 are arranged along the third corner 4 The diagonal direction of each is uniformly spaced, N is a natural number greater than or equal to 3 and less than or equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com