Device and method for automatic circumferential ultrasonic detection of joint of polyolefin composite tube

An automatic detection device and ultrasonic technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of lack of quality information on the fusion surface, time-consuming, labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be emphasized here that each module described in the present invention is a collection of circuit logic, not a virtual function module. Its specific implementation is a common technical means in the field, and those skilled in the art can completely reproduce it according to the conventional technical means mastered by them after reading the present invention. There is no methodological feature in the present invention, which can be practiced in the art even without the circuit diagram.

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

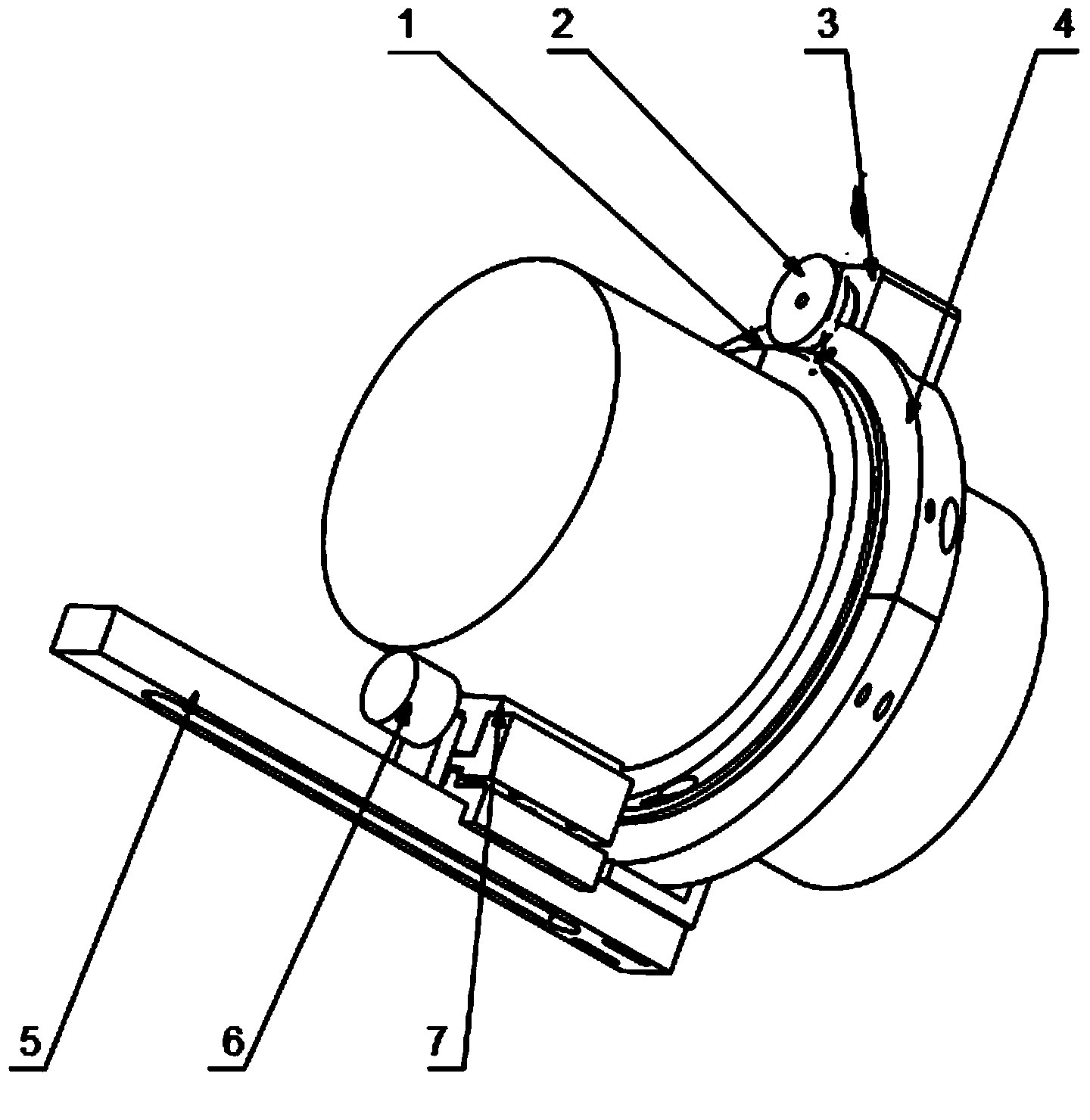

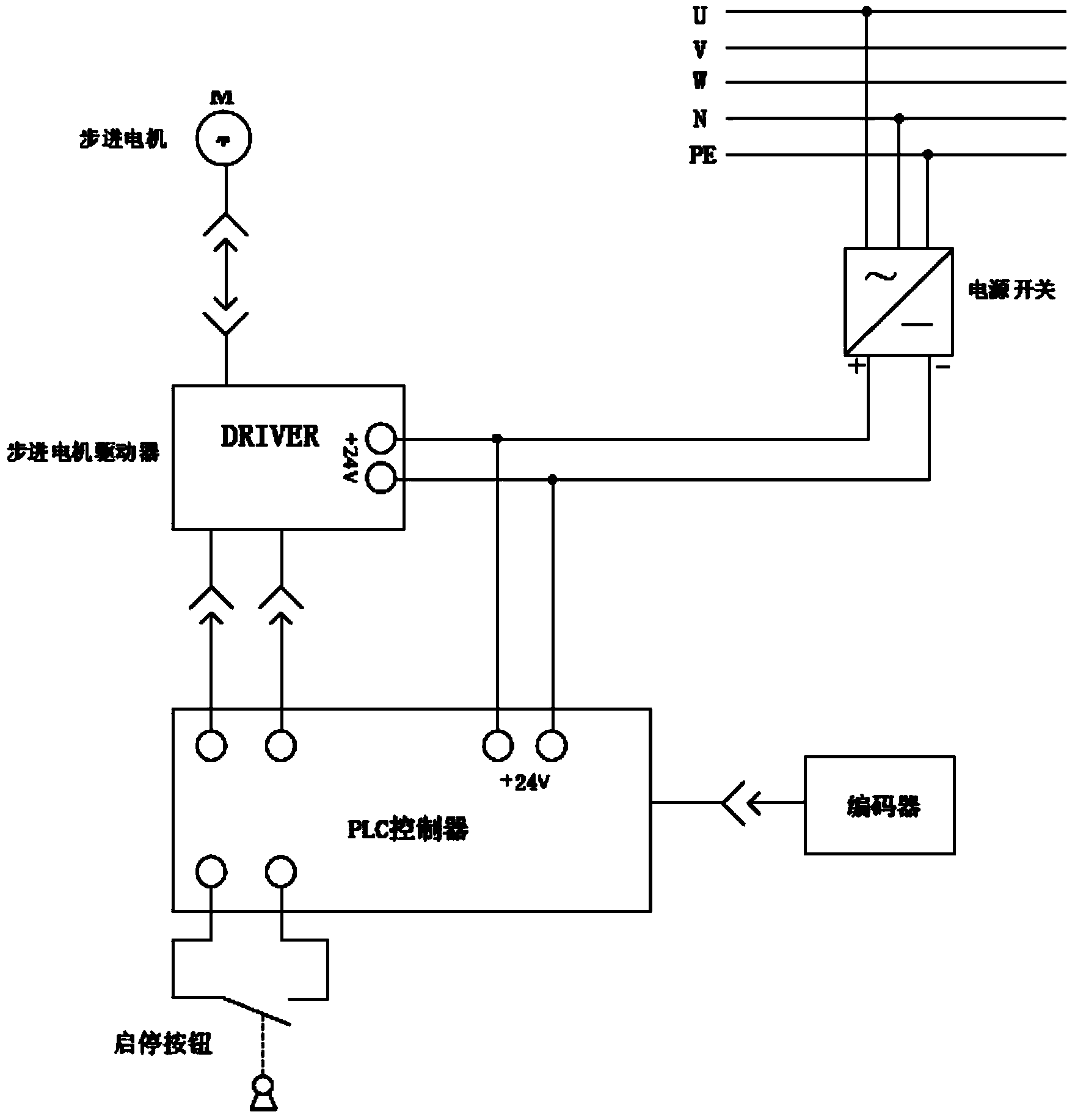

[0022] The ultrasonic circumferential automatic detection device for polyolefin composite pipe joints includes an ultrasonic detector, a probe 7, a probe clamping device 5, a wheel encoder 6, an inner clamp 1, an outer clamp 4, a pinion 2, a stepping motor 3 and control module. Such as figure 1 As shown, the outer clamp 4 is set on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com