Novel method for recovering waste and old polystyrol

A technology of waste polystyrene and polystyrene, which is applied in recycling technology, plastic recycling, etc., can solve the problems of low quality polystyrene, complex equipment, expensive price, etc., and achieves no secondary pollution and important industrial value , The effect of small solvent loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

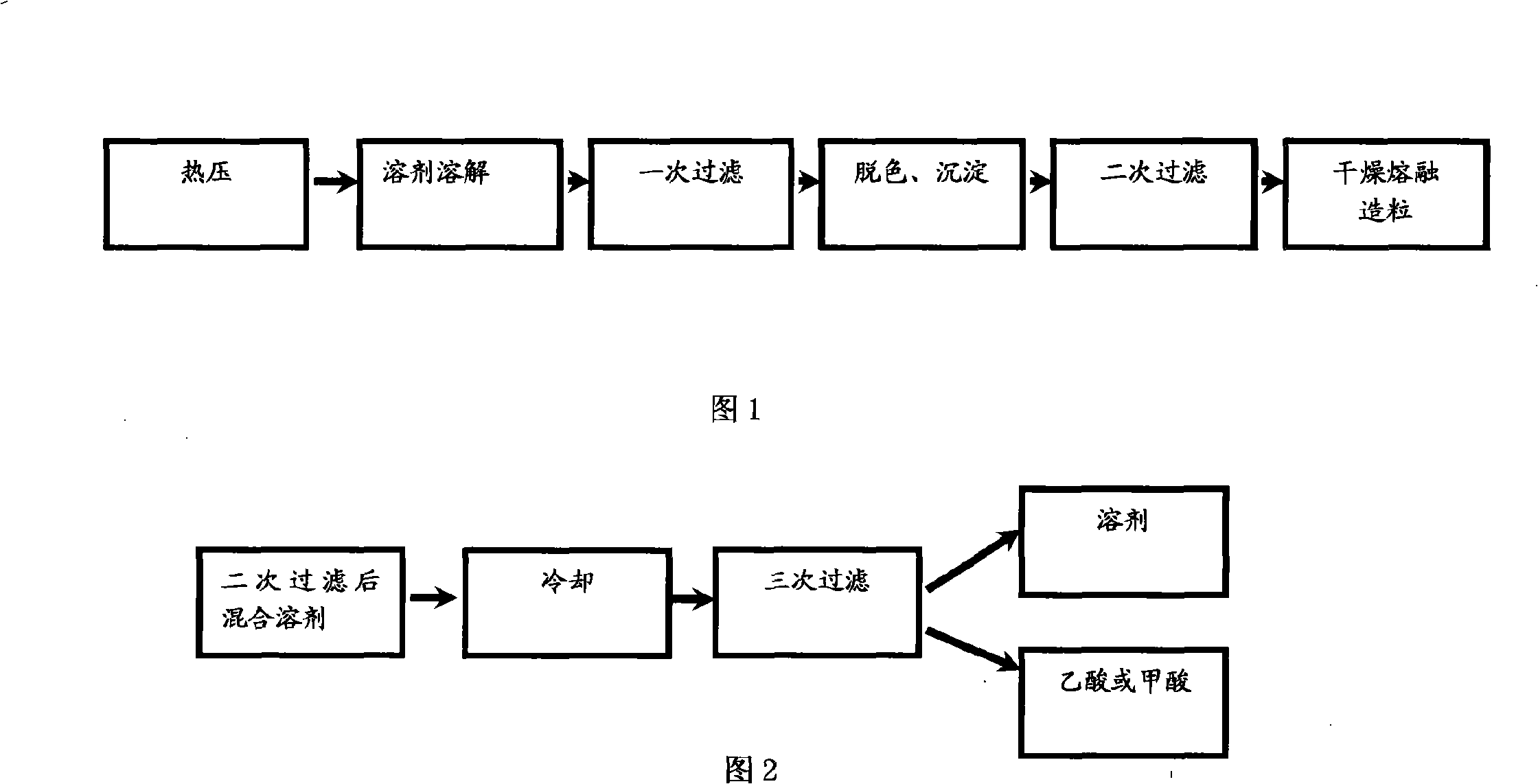

Method used

Image

Examples

Embodiment 1

[0027] Example 1 100g of waste polystyrene was subjected to 60°C, 1.2MP hot pressing for 5 minutes, and was dropped into 100ml of ethyl acetate solution for 10 seconds. After 10 seconds, the polystyrene was completely dissolved and filtered through a 100-mesh filter screen for the first time, and then in Add 30ml of acetic acid to the filtered solution, and filter it through a 40-mesh filter screen for a second time after 1 minute. The filtered polystyrene solid is dried at a temperature of 80°C for 1 hour, and melted and granulated; Cool to -10°C, separate acetic acid and ethyl acetate by filtration.

Embodiment 2

[0028] Example 2 1000g of waste polystyrene was subjected to 80°C, 0.9MP hot pressing for 8 minutes, and after being put into 800ml of toluene solution for 30 seconds, the polystyrene was completely dissolved and filtered through a 200-mesh filter screen for the first time, and then after filtration 400ml of formic acid was added to the solution, and after 3 minutes, it was filtered twice through a 40-mesh filter, and the filtered polystyrene solid was dried at 90°C for 1 hour, melted and granulated; the solvent was cooled to -25°C by liquid nitrogen, Formic acid and toluene were separated by filtration.

Embodiment 3

[0029] Example 3 5000g of waste polystyrene was subjected to 70°C and 0.8MP hot pressing for 15 minutes, and was dropped into 4000ml of chloroform solution for 60 seconds. After 60 seconds, the polystyrene was completely dissolved and filtered through a 200-mesh filter screen for the first time, and then in Add 1500ml of acetic acid to the filtered solution, and carry out secondary filtration through a 40-mesh filter screen after 5 minutes. The filtered polystyrene solid is dried at a temperature of 95° C. for 1 hour, melted and granulated; a small amount of white carbon black is added to the solvent as a form Nucleating agent, cooled to -5°C with liquid ammonia, and filtered to separate acetic acid and chloroform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com