Steel bar concrete dense rib floor

A technology of reinforced concrete and dense ribs, applied to floors, building components, buildings, etc., can solve the problems of time-consuming and laborious, slow construction progress, and excessive formwork wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

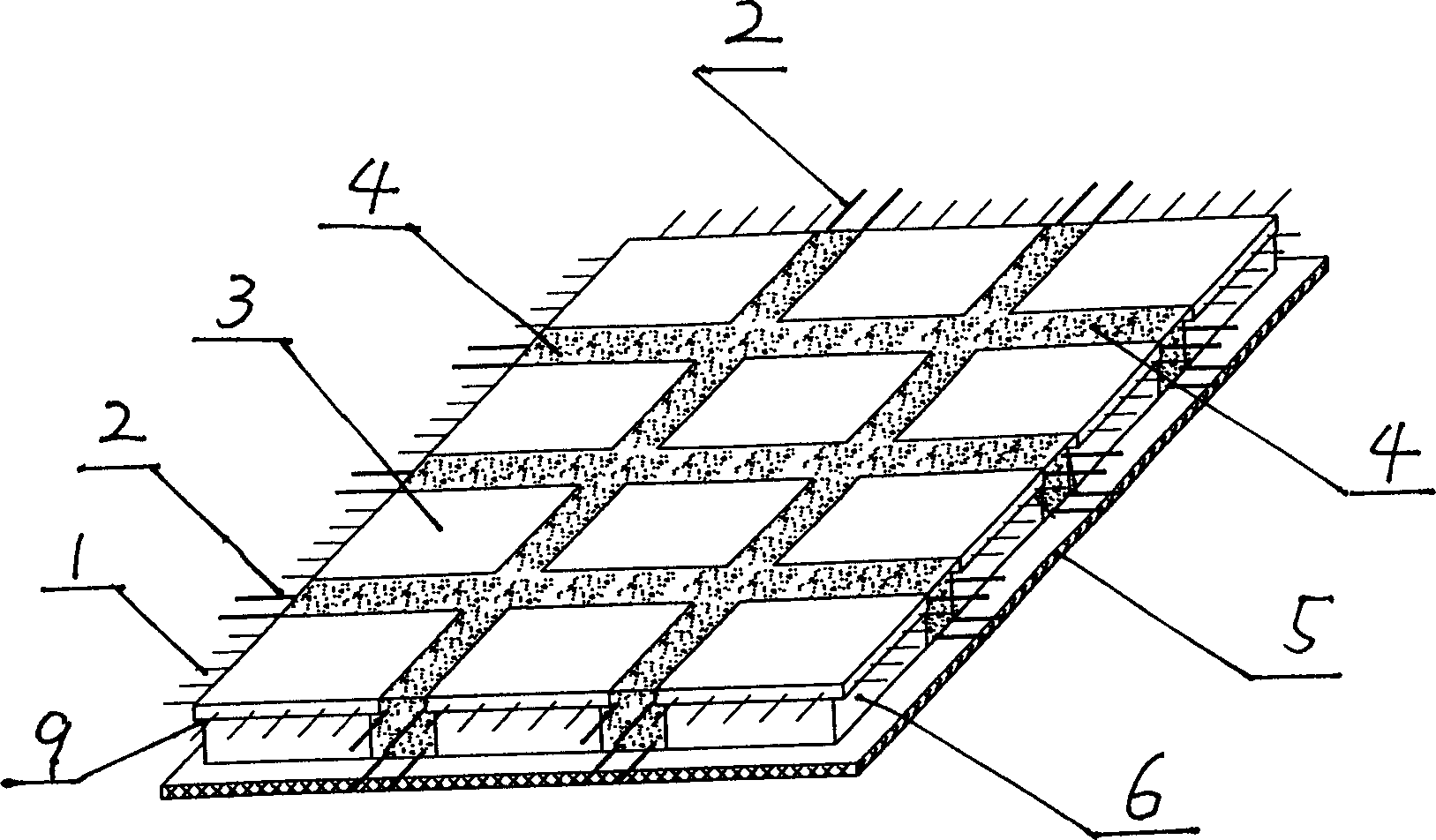

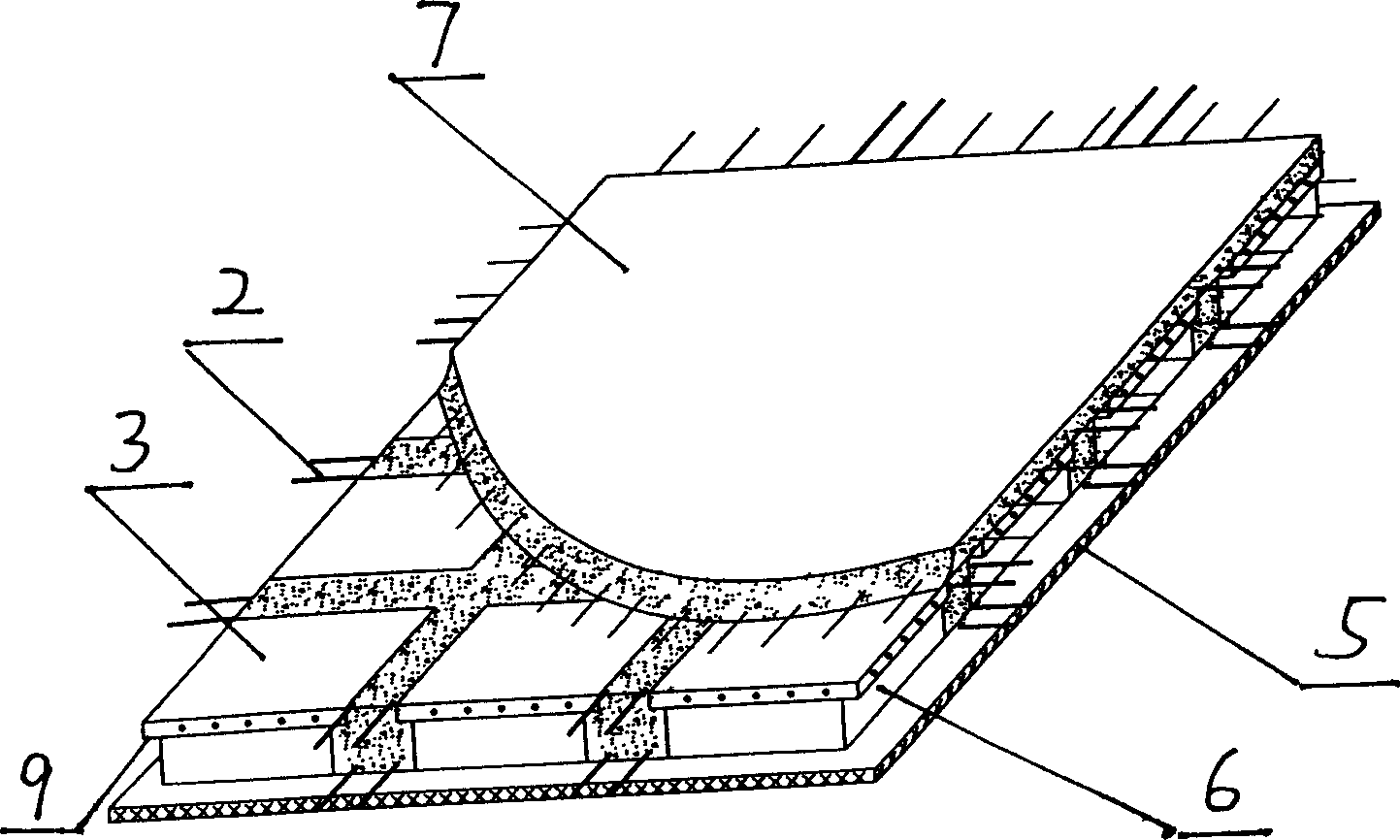

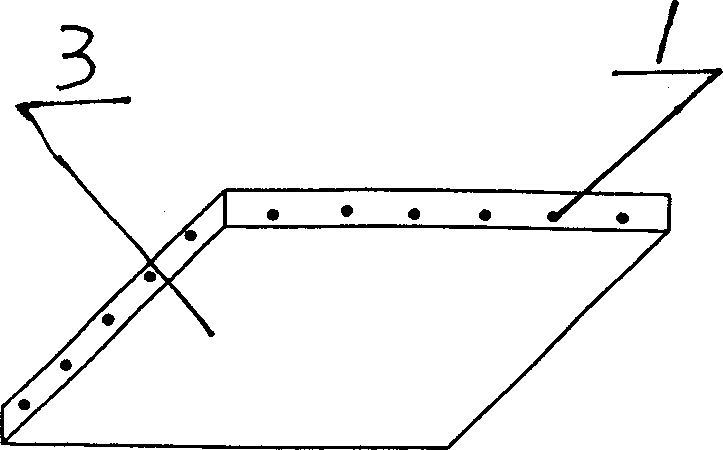

[0022] refer to figure 1 -- Figure 12 , the reinforced concrete ribbed floor slab includes prefabricated components, dense ribs, and the floor slab is composed of multiple prefabricated components assembled on the dense ribs. The prefabricated components are hollow component frame 6, reinforced concrete prefabricated component cover 3, hollow component frame 6, reinforced concrete The prefabricated component cover 3 forms an assembly unit, and the floor slab is arranged vertically and horizontally by a plurality of assembly units, which are assembled on the vertical and horizontal dense ribs 4 to form a densely ribbed floor slab.

[0023] The above assembly unit is a hollow component frame 6, a reinforced concrete prefabricated component cover 3, a plurality of hollow component frames 6 are arranged vertically and horizontally, placed on the formwork 5, the prefabricated component cover 3 is covered on the hollow component frame 5, the prefabricated component cover 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com