Hot air circulating heating insulation device and method for using same

A heating and heat preservation, hot air circulation technology, applied in heating devices, applications, household appliances, etc., can solve the problems of energy consumption, poor operability and controllability, waste of fuel, etc., to reduce energy use loss, temperature The adjustment is convenient and fast, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

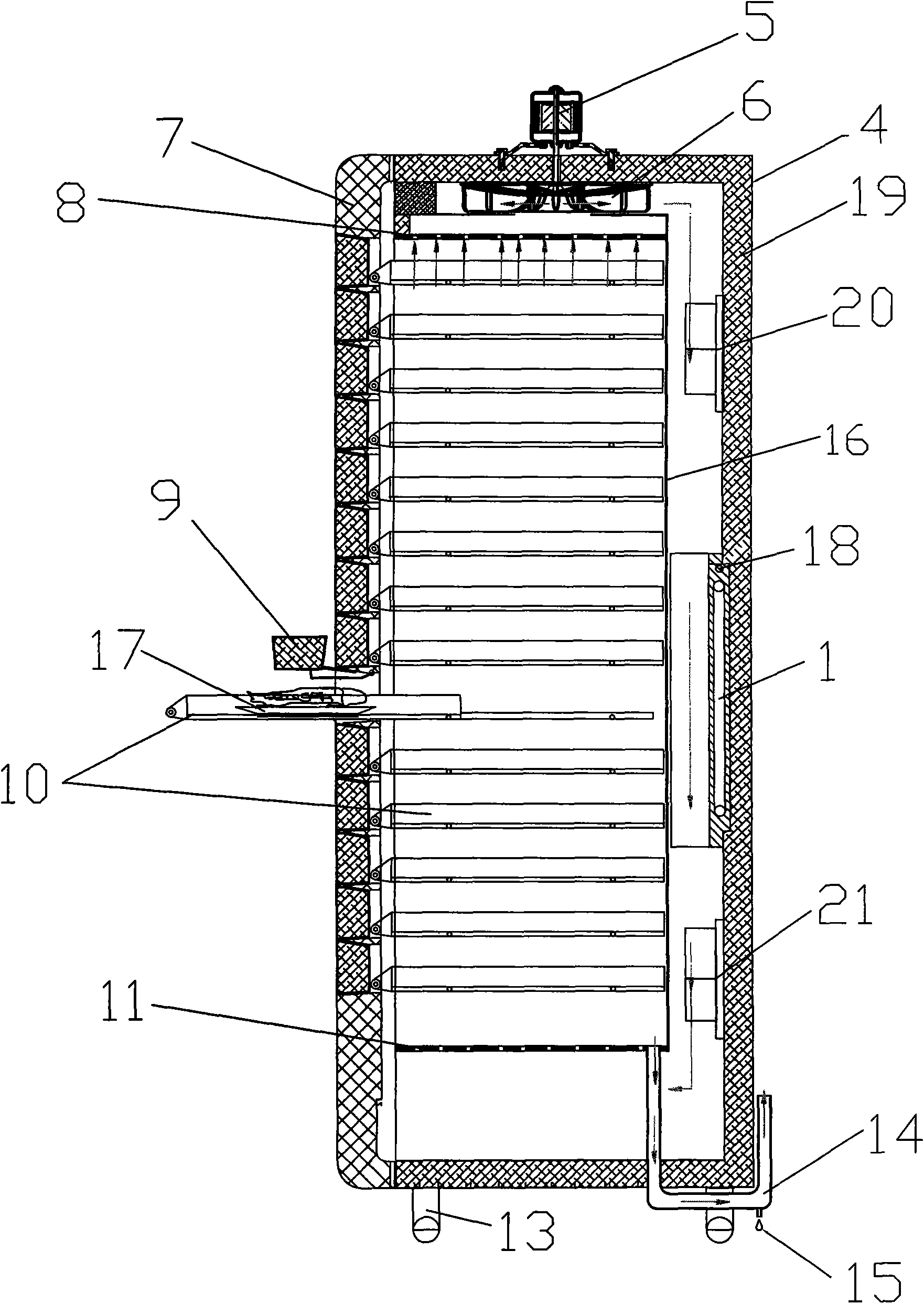

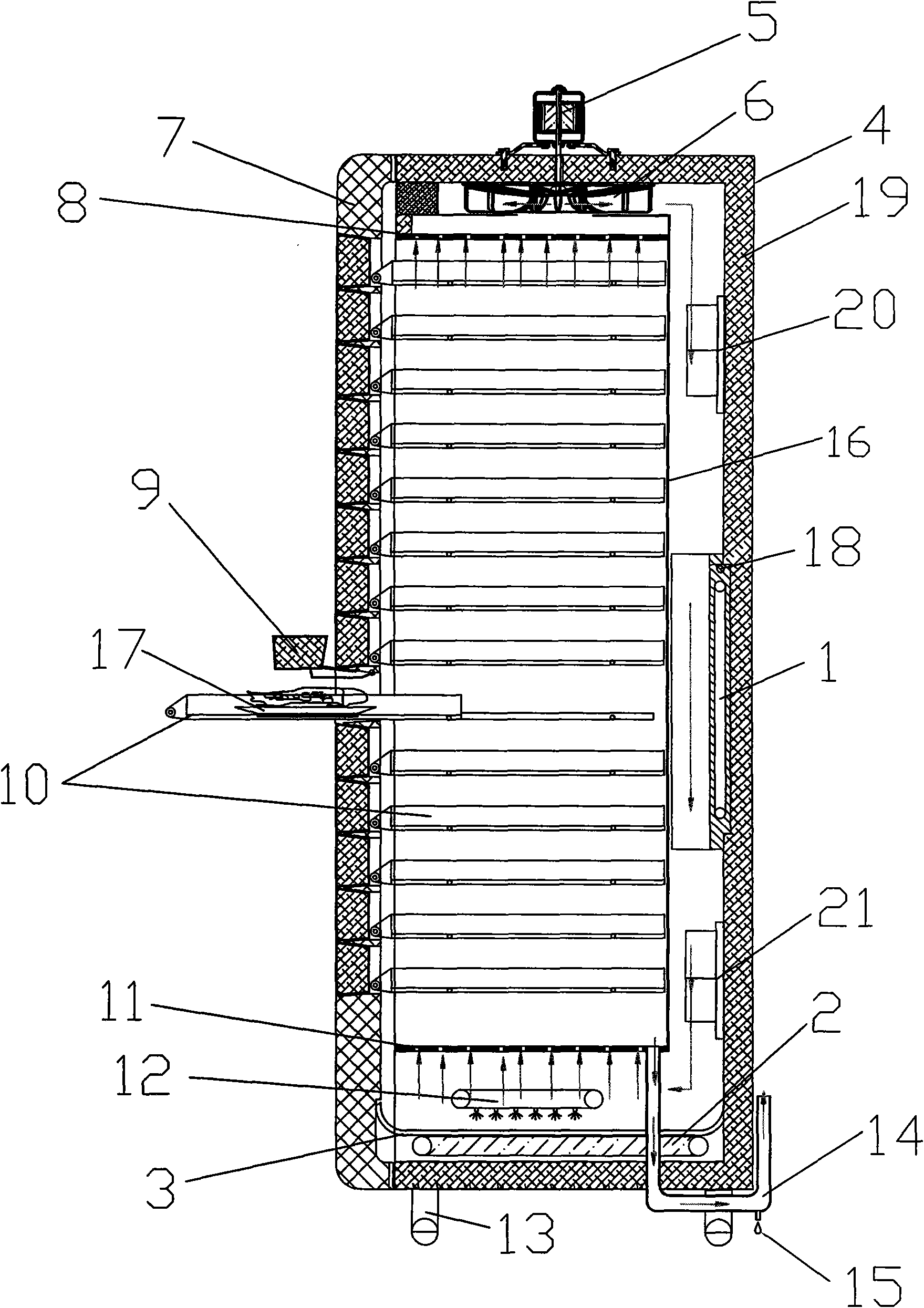

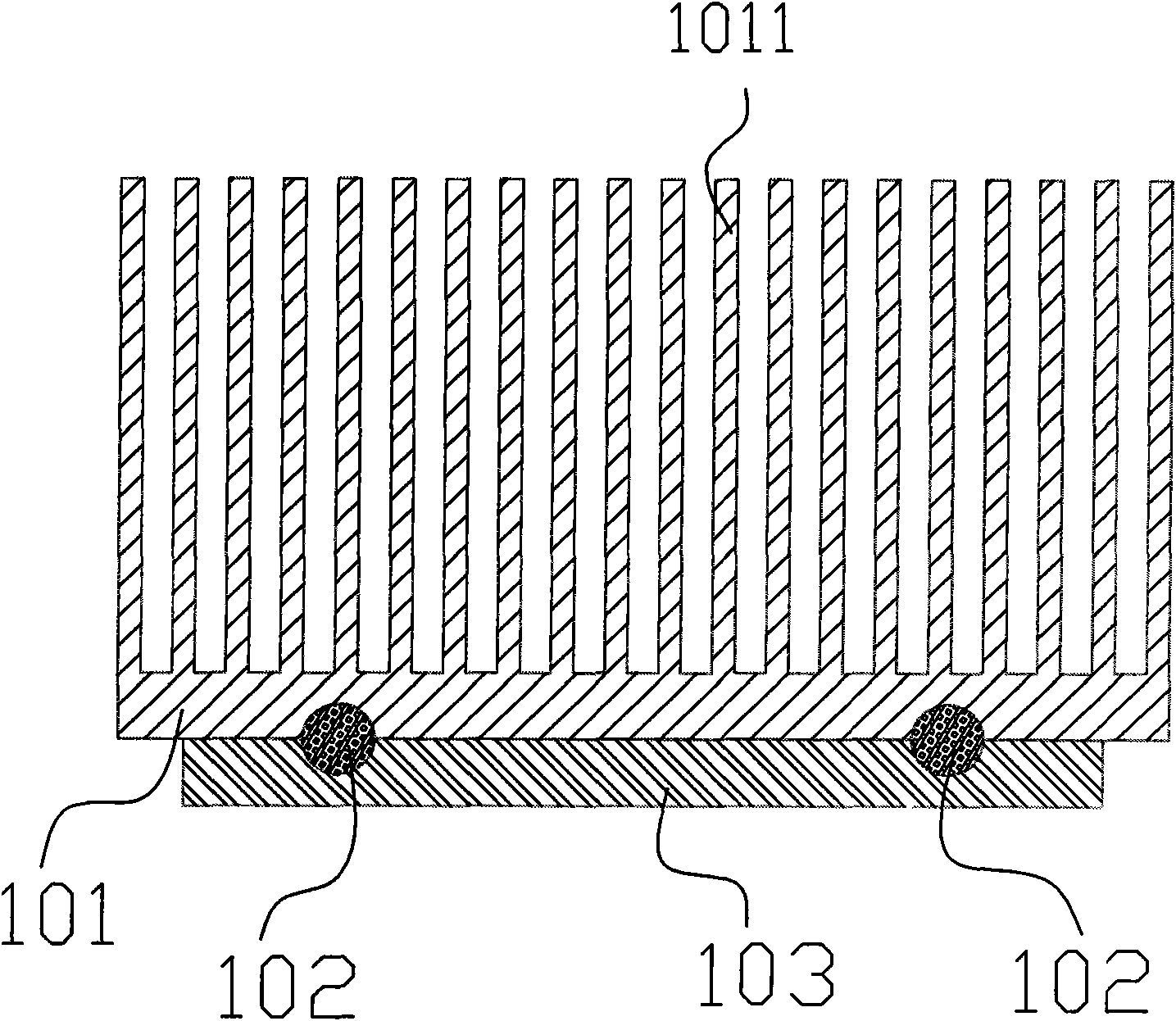

[0070] Example 1, see figure 1 . The device of the present embodiment comprises a casing 4 with an insulating layer 19, a casing door 7 and an electric heating device 1; Appropriate gaps are left on the top board, the bottom board and the rear wall respectively, and multiple layers of mutually parallel drawable cages 10 are arranged in the inner box 16; the top board and the bottom board of the inner box 16 are respectively a The uniform gas partition 8,11;

[0071] Open the mouth corresponding to the cage 10 on said box door 7, and arrange the unit door 9 with insulation layer on the mouth; In addition: a circulation fan 6, this circulation fan 6 is contained in the inner box 16 and In the space between the top plates of the box body 4, its drive motor 5 can be installed outside the top of the box body 4;

[0072] Above-mentioned electric heater 1 is a gas heater, and this gas heater is contained in the space between inner box 16 and the rear wall of casing 4, and this sp...

Embodiment 2

[0076] Example 2, see Figure 4 . In order to realize the automation of the device, a control device can also be added on the basis of the above-mentioned scheme, and the circuit of the control device includes:

[0077] One CPU25, this CPU25 is connected with CPU power supply 23, input, output interface circuit 24, analog-to-digital converter 28, clock oscillating circuit 26 and keyboard 27 respectively; Fan controller 6.1, gas heating controller 1.1, steam heating controller 2.1, water mist controller 211.1 are connected and powered; input and output interface circuit 24 is connected with fan controller 6.1 and fan 6, gas heating controller 1.1 and Gas heater 1, steam heating plate controller 2.1 and steam heating plate 2 are connected with water mist controller 211.1 and water mist electromagnetic switch 211, and are connected to control mains power supply to expand various protection circuits; analog-to-digital converter 28 It is respectively connected with two temperatur...

Embodiment 3

[0078] Embodiment 3, see Figure 5 . The method for using the device of the above-mentioned embodiment comprises the following steps:

[0079] Step 01: Turn on the power;

[0080] Step 02: Start the circulation fan;

[0081] Step 03: Start the gas heater;

[0082] Step 04: Measure the temperature of the lower part of the box body by the temperature and humidity sensor 21; if the temperature does not reach the set temperature, then adjust the heating power of the gas heater again for further heating;

[0083] Step 05: Measure the temperature of the upper part of the box by the temperature and humidity sensor 20; if the set temperature is not reached, start the gas heater again for further heating; if the set temperature is reached, proceed to the next step;

[0084] Step 06: Stop gas heating and continue to keep warm;

[0085] Step 07: Finishing.

[0086] After the power is turned on, the gas heater 1 and the circulating fan 6 start to work; the hot gas moves upwards thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com