Anti-collision laser head and laser cutting machine and laser head anti-collision method

A technology of laser cutting machine and laser head, which is applied in the field of anti-collision laser head, which can solve the problems of laser head damage, workpiece easy to hit the laser head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

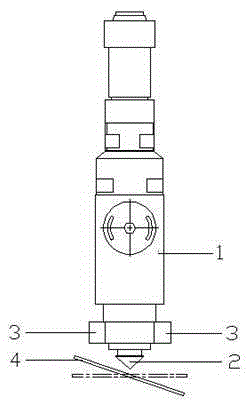

[0018] Please refer to figure 1 , an anti-collision laser head of the present invention, which can prevent the laser head from colliding with an overturned workpiece and damage the laser head. A distance sensor 3 is arranged, and the distance sensor 3 measures the distance from the highest point of the cut workpiece to the lowest point of the laser nozzle. In this embodiment, the laser head main body 1 is provided with two distance sensors 3 , and the two distance sensors 3 are respectively located on opposite sides of the laser head main body 1 . At the same time, four distance sensors 3 can also be arranged on the laser head main body 1 , and the four distance sensors 3 are evenly distributed around the laser head main body 1 . The distance sensor 3 is located at the lower end of the laser head main body 1 .

[0019] The present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com