Preparation method of food packaging bag code spraying device facilitating positioning

A packaging bag and coding technology, which is applied in packaging, printing devices, printing, etc., can solve the problems of position deviation and easy generation of static electricity when printing packaging bags, and achieve the effects of avoiding displacement, removing static electricity, and facilitating positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

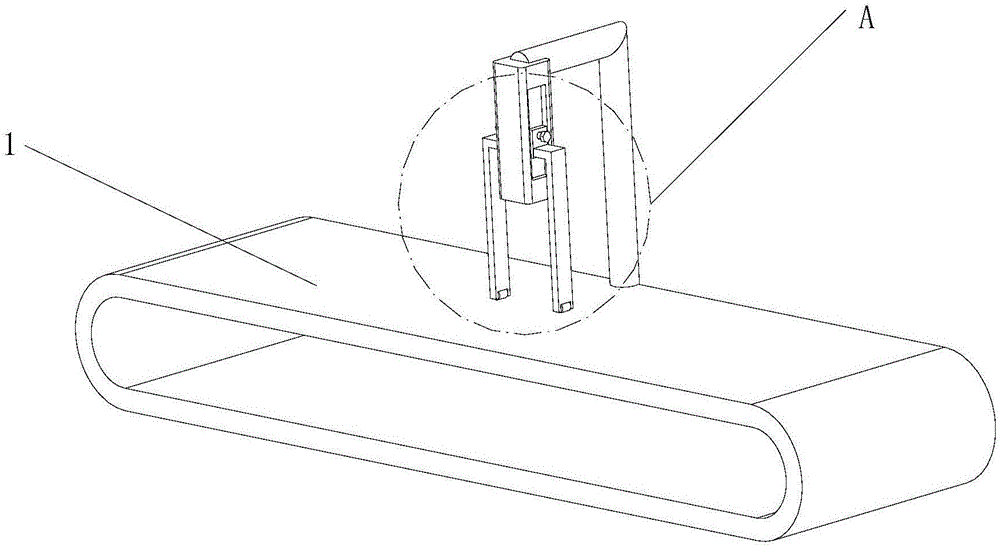

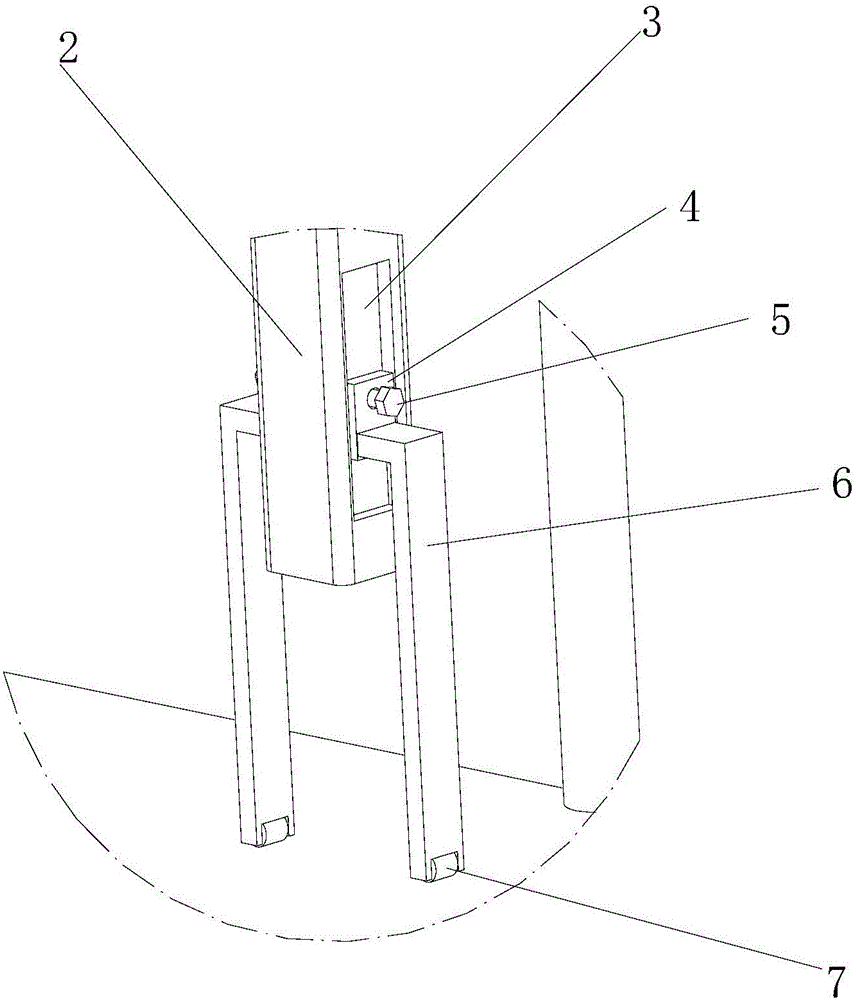

[0012] like figure 1 , 2 As shown, the present invention provides a method for preparing a food packaging bag inkjet device that is convenient for positioning, including a transmission unit 1, a bracket, an inkjet printer body 2, and two groups of auxiliary positioning units located on both sides of the inkjet printer unit. The printer body 2 is fixed on the bracket, and the laser nozzle on the inkjet printer body 2 faces the conveying surface of the conveying unit 1;

[0013] The auxiliary positioning unit includes a boom 6 and an iron roller 7, the upper end of the hook is connected to the side of the inkjet printer body 2, and the iron roller 7 is located at the lower end of the boom 6;

[0014] There is a gap between the iron roller 7 and the conveying surface of the conveying unit 1 to allow food packaging bags to pass through.

[0015] When the food packaging bag passes through the gap between the iron roller 7 and the conveying surface, the iron roller 7 can discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com