Inner-cooling nozzle for laser cladding

A technology of laser cladding and nozzle, which is applied in metal material coating process, coating and other directions, can solve the problems of danger, explosion, damage to the nozzle, etc., and achieve the effect of good cladding effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

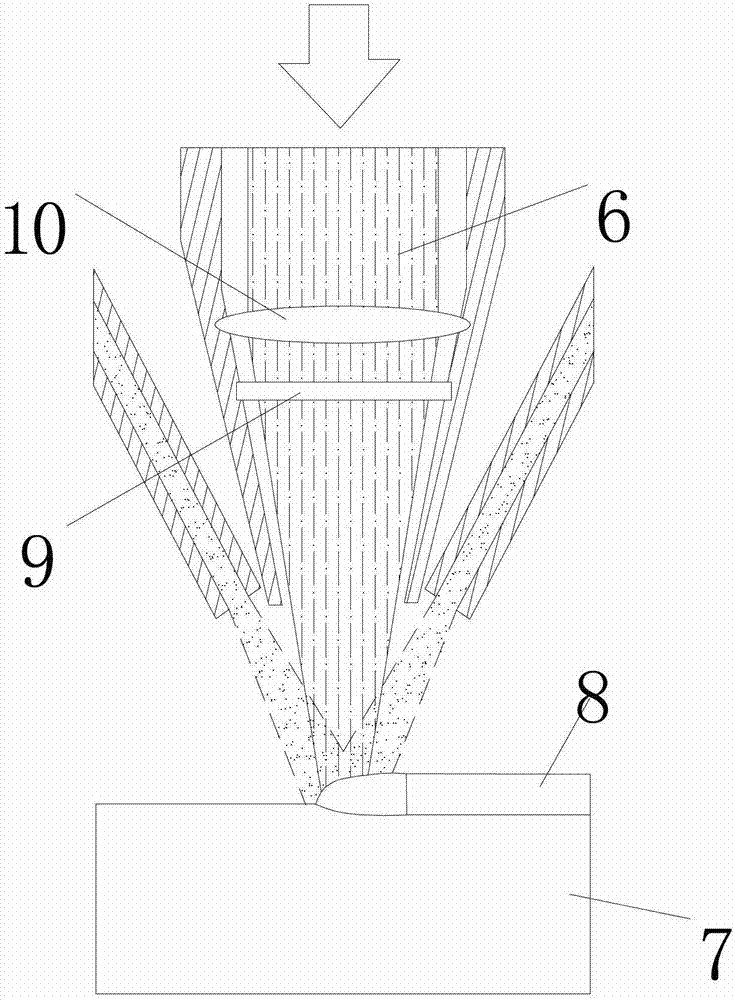

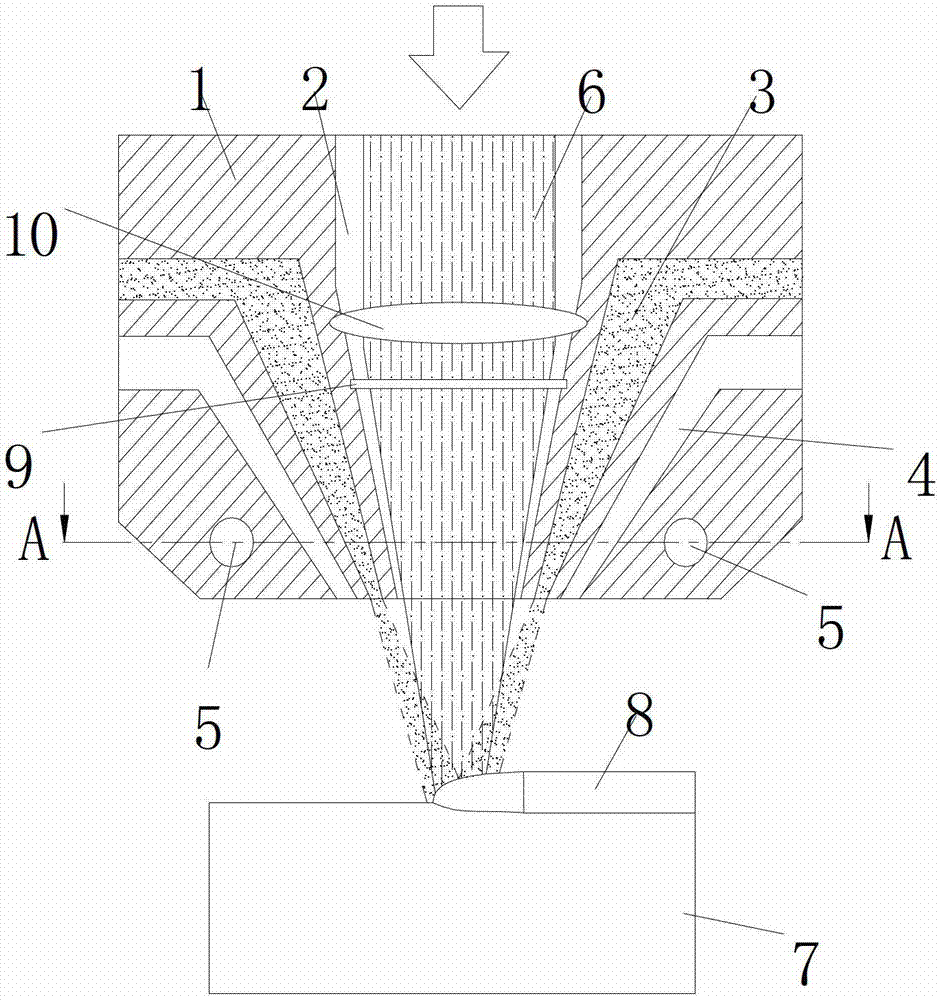

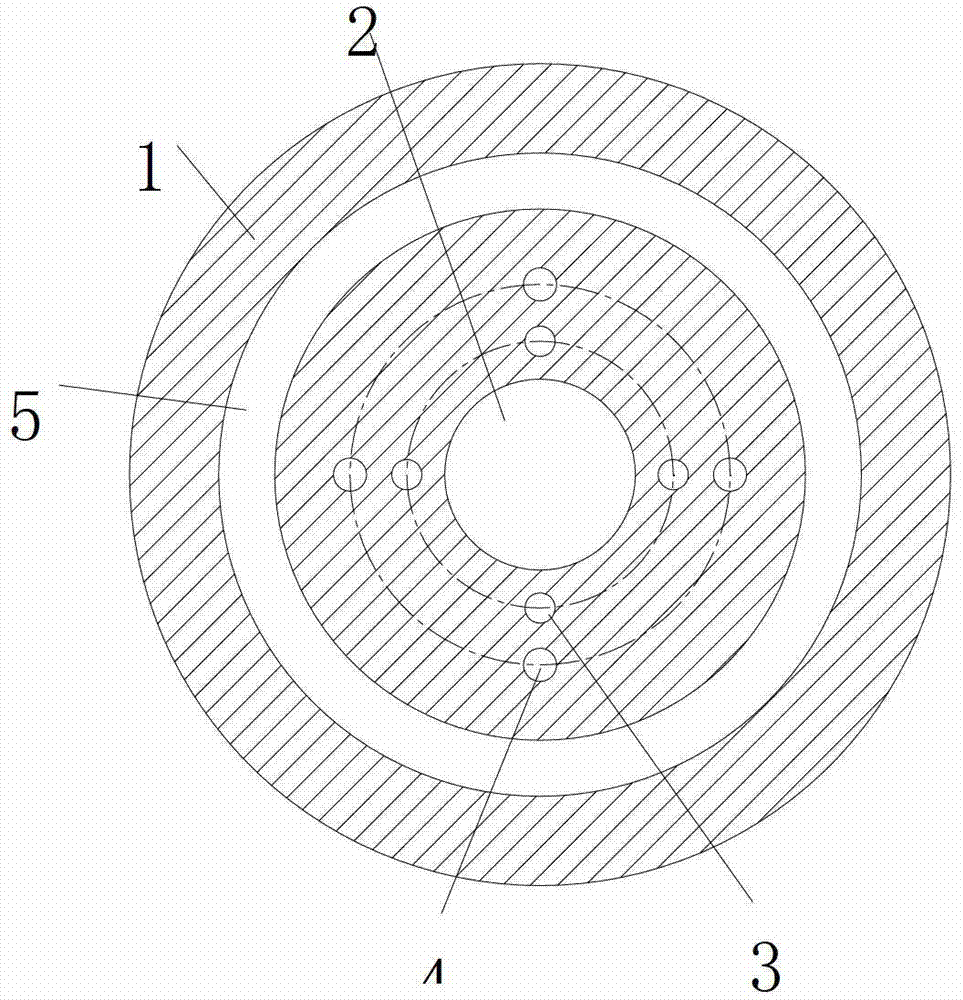

[0023] From attached figure 2 And attached image 3 It can be seen from the schematic diagram of the structure that the present invention provides an internal cooling nozzle for laser cladding, which has a laser channel 2 in the center of the nozzle 1, a powder channel 3 around the laser channel 2, and a The protective gas channel 4 on the periphery of the powder channel 3, and the annular cooling channel 5 opened on the spray head 1 and leading to high-pressure air or liquid. The laser beam 6 enters the laser channel 2 and passes through the focusing lens 10 and the protective lens 9 .

[0024] In this embodiment, there are multiple powder channels 3, which are evenly distributed around the central axis of the laser channel 2, and the extension lines of each powder channel 3 in its length direction meet the central axis of the laser channel 2 below the nozzle 1 at one point. The powder channel 3 can also be an integral channel with the central axis of the laser channe...

Embodiment 2

[0028] as attached Figure 4 As shown, the difference between the internal cooling nozzle for laser cladding in this embodiment and the first embodiment is that there are multiple annular cooling channels 5 . The size and thickness of each annular cooling channel 5 can be set according to the difference of the installation position and the requirement of the cooling effect.

Embodiment 3

[0030] as attached Figure 5 As shown, the difference between the internal cooling nozzle for laser cladding in this embodiment and the first embodiment is that the annular cooling channel 5 is replaced by a spiral cooling channel, and the central axis of the spiral cooling channel is in line with the laser channel 2 coincident with the central axis.

[0031] Since the lower part of the shower head 1 is the place with the highest temperature in the whole shower head, the spiral cooling channel passes through the lower part of the shower head 1 . The position and direction of the spiral cooling channel can be set according to actual needs. It should be noted that the spiral cooling channel cannot communicate with the powder channel 3 and the protective gas channel 4 . The starting end of the spiral cooling channel in this embodiment is located above the powder channel 3 , passing between the powder channel 3 and the shielding gas channel 4 , and the ending end is at the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com