Water induced laser nozzle anti-sputtering protector

A protection device, laser technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of adjustment operation of lengthy working time, water splash and water vapor filling, micro water column back splash and other problems, to prevent damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

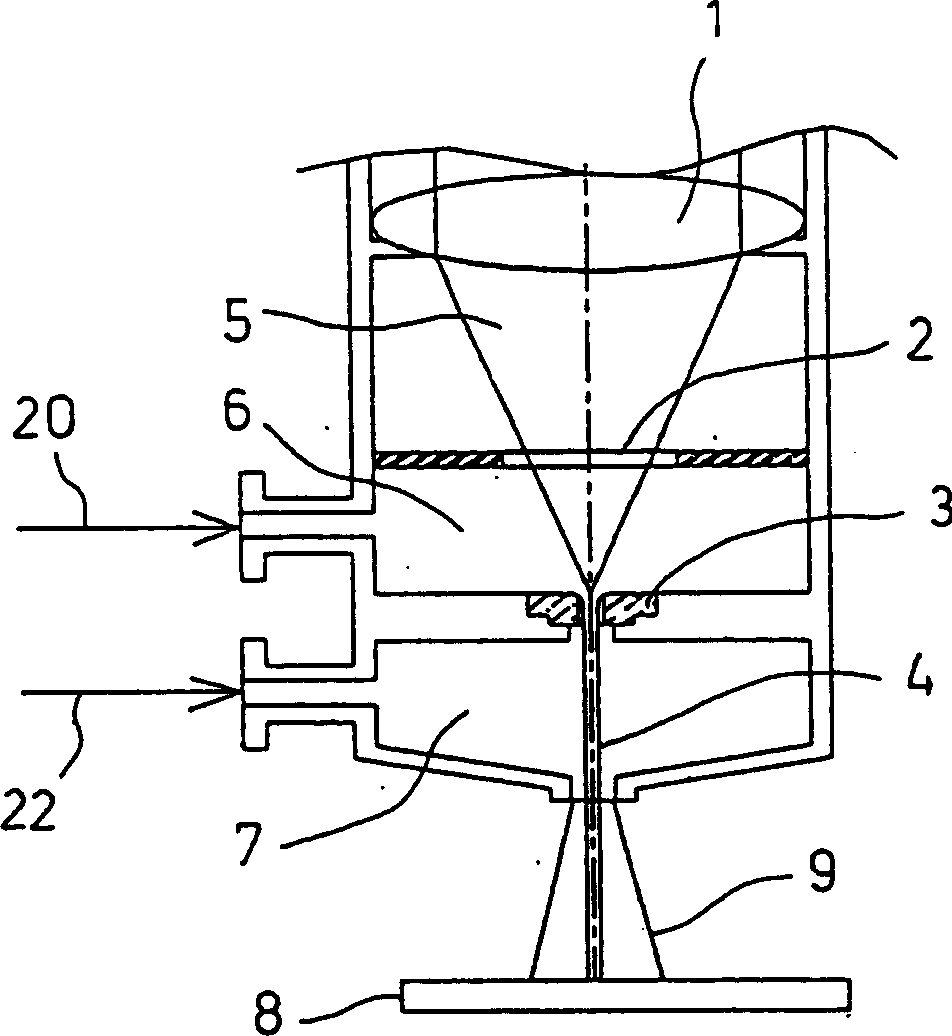

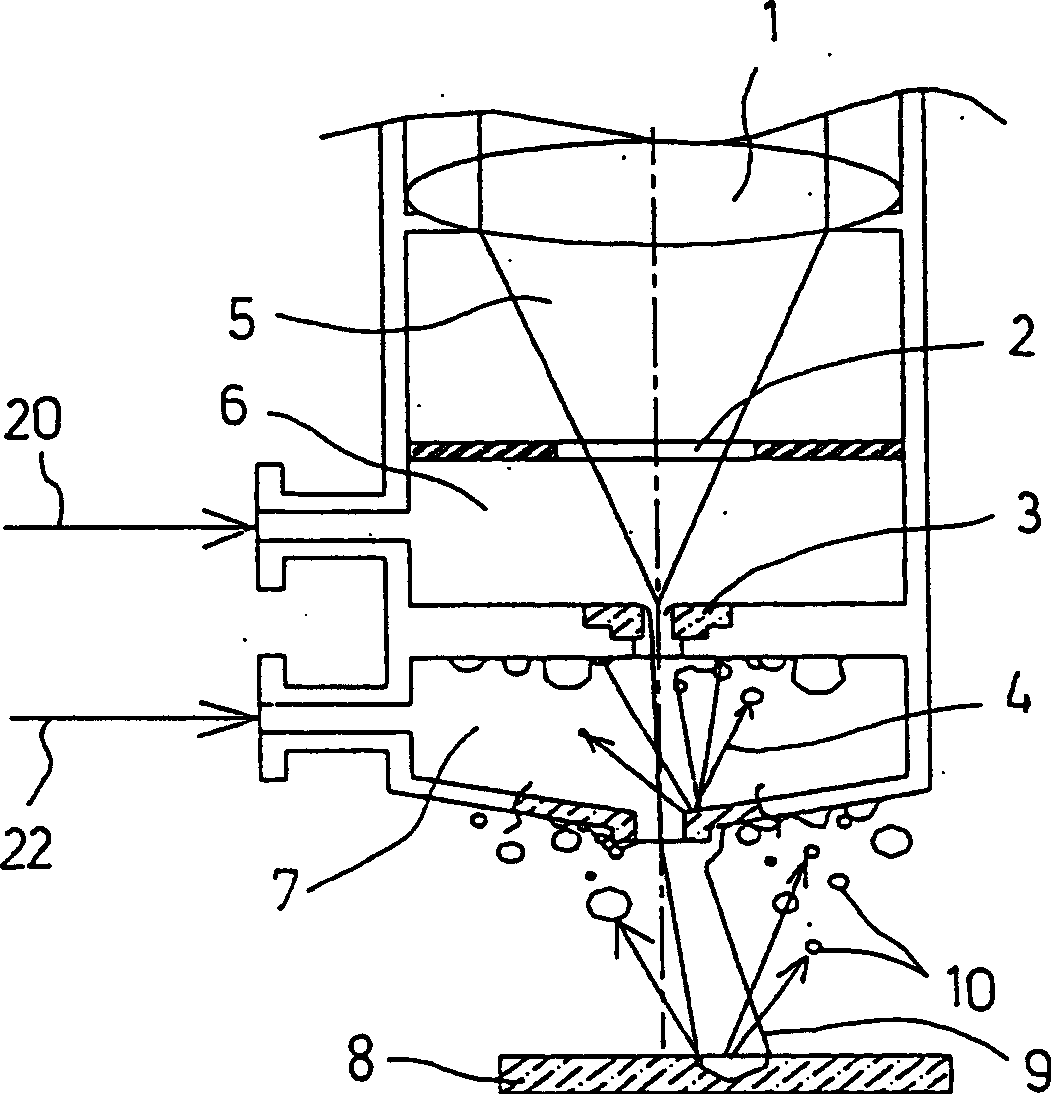

Method used

Image

Examples

Embodiment Construction

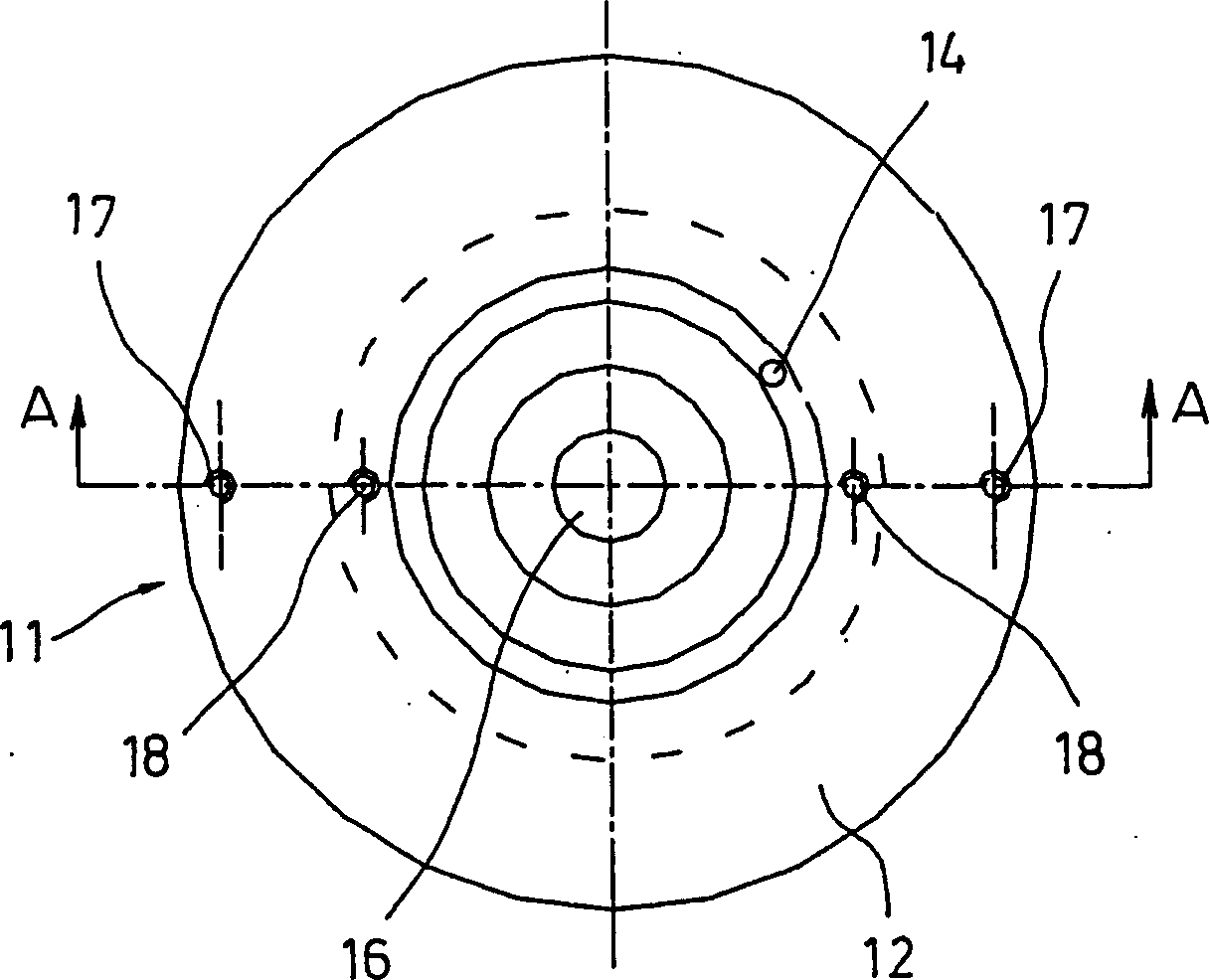

[0019] As shown in Fig. 3 (a) and Fig. 3 (b), splash guard 11 comprises a base plate 12, and a central plate 13 is surrounded by base plate 12, and the central point of central plate 13 is provided with a central penetration hole 16, in order to For the micro water column of the water guide laser cutting machine to pass through. An anti-flow groove 14 is disposed between the bottom plate 12 and the center plate 13 to prevent water droplets from flowing from the surface of the bottom plate 12 to the surface of the center plate 13 . A pair of first fixing holes 17 and a pair of second fixing holes 18 are further disposed on the bottom plate 12 , and their functions will be described in detail later.

[0020] Fig. 3(b) shows a cross-sectional view seen from the A-A plane of Fig. 3(a). As shown in Figure 3 (b), the screw is locked into the center plate 13 and connected to the base plate 12 through the second fixing hole 18, the center plate 13 is connected to a power line 15, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com