5-shaft linkage calibrating method of laser drilling machine

A technology of laser drilling machine and calibration method, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as deformation, corrosion, lack of 5-axis linkage calibration method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

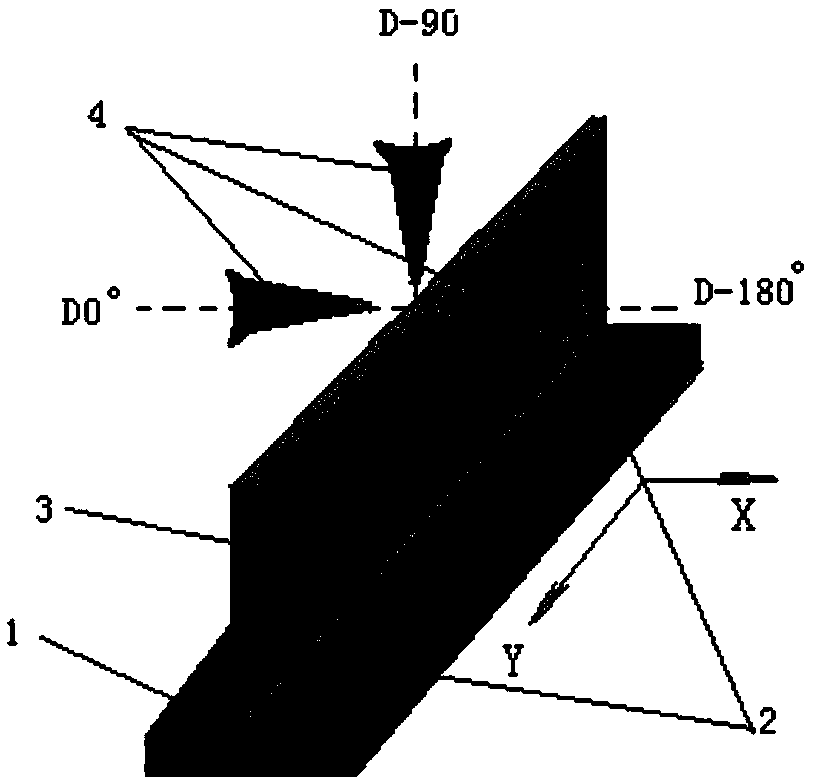

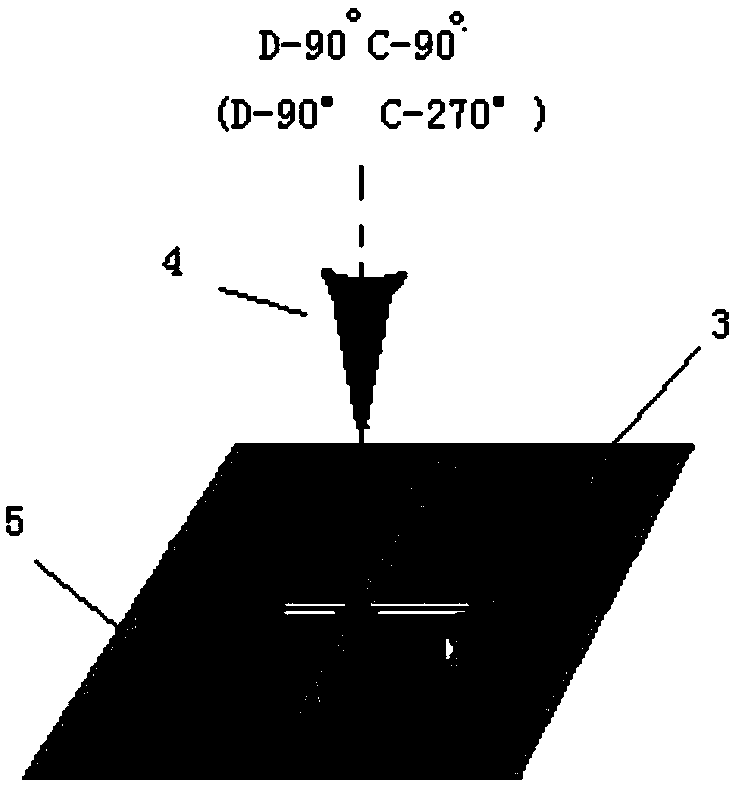

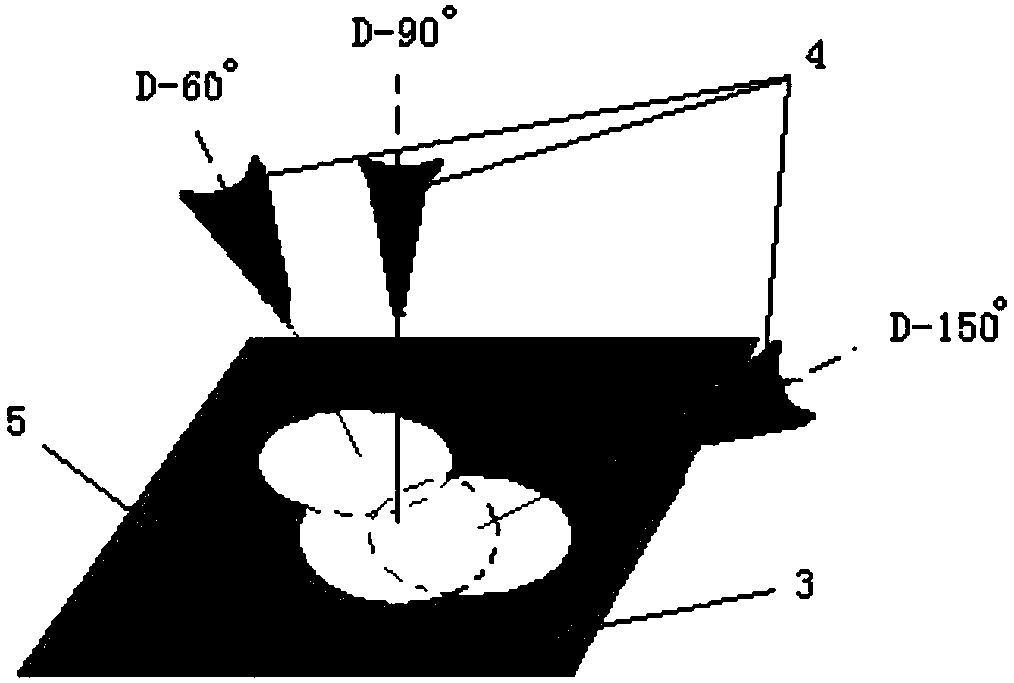

[0050] A 5-axis linkage calibration method for a laser drilling machine. It should be noted that in the calibration process, the D-axis needs to be calibrated first, and then the C-axis needs to be calibrated, so that the compensation value can take effect. Secondly, during the calibration process of the laser drilling machine, the spatial coordinates of the 5-axis linkage change greatly, so it is necessary to clean up the surroundings of the workbench in advance to avoid interference or collision.

[0051] Definition: the D axis is the rotation axis that rotates around any axis in the XY plane,

[0052] D-axis rotation The laser beam is irradiated vertically downward, the D-axis is -90°, the D-axis rotates counterclockwise to the horizontal state is 0°, and the D-axis rotates clockwise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com