Optical fiber IMU total-temperature calibration compensation method

A compensation method and temperature compensation technology, which is applied in the fields of inertial measurement and navigation, can solve the problems of high performance requirements for calibration test equipment and the inability to meet low-cost calibration, and achieve the effect of reducing test equipment costs, reducing test costs, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

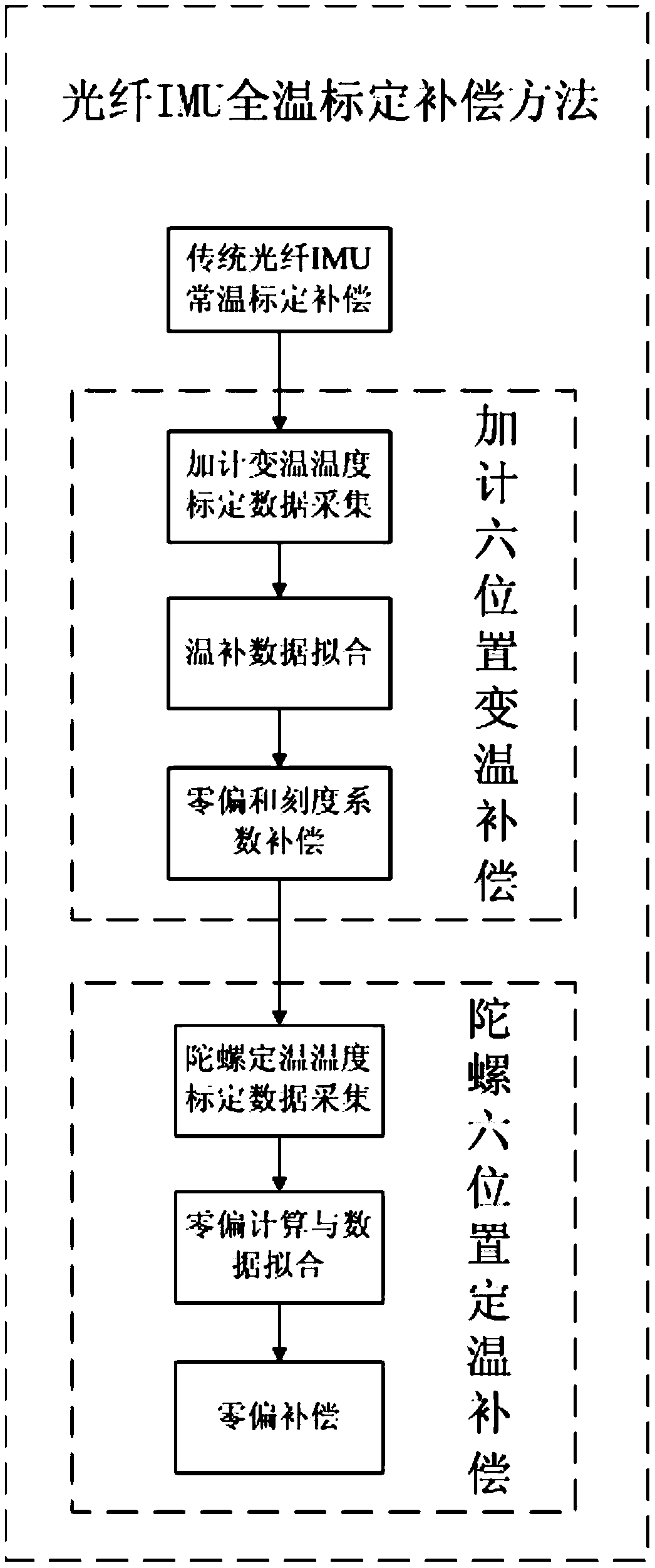

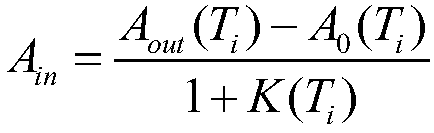

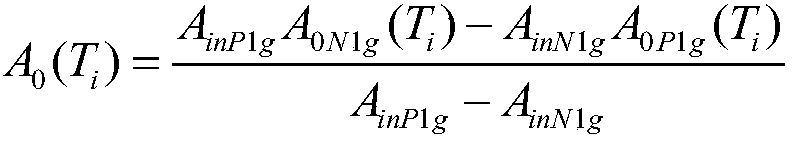

[0053] see figure 1 , the present invention provides an optical fiber IMU full temperature calibration compensation method, including constant temperature calibration compensation, accumulative zero bias and scale coefficient temperature compensation, and gyro zero bias temperature compensation. The accuracy requirements of the navigation control system, on the other hand, can ensure that the full temperature calibration compensation is completed by using low-cost low-performance calibration equipment under the environmental conditions that cannot meet the high-performance calibration. Specific steps are as follows:

[0054] S1, fixed temperature calibration compensation

[0055] The traditional multi-position method is used to realize the constant temperature calibration compensation of the accumulator; the traditional angular position method is used to realize the calibration coefficient calibration compensation of the gyroscope; the traditional multi-position method is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com