Laser processing machine condensing lens dirt detecting method and device

A laser processing machine and condenser lens technology, applied in the direction of measuring devices, laser welding equipment, metal processing equipment, etc., can solve the problems of complex structure of the processing head and achieve the effect of simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

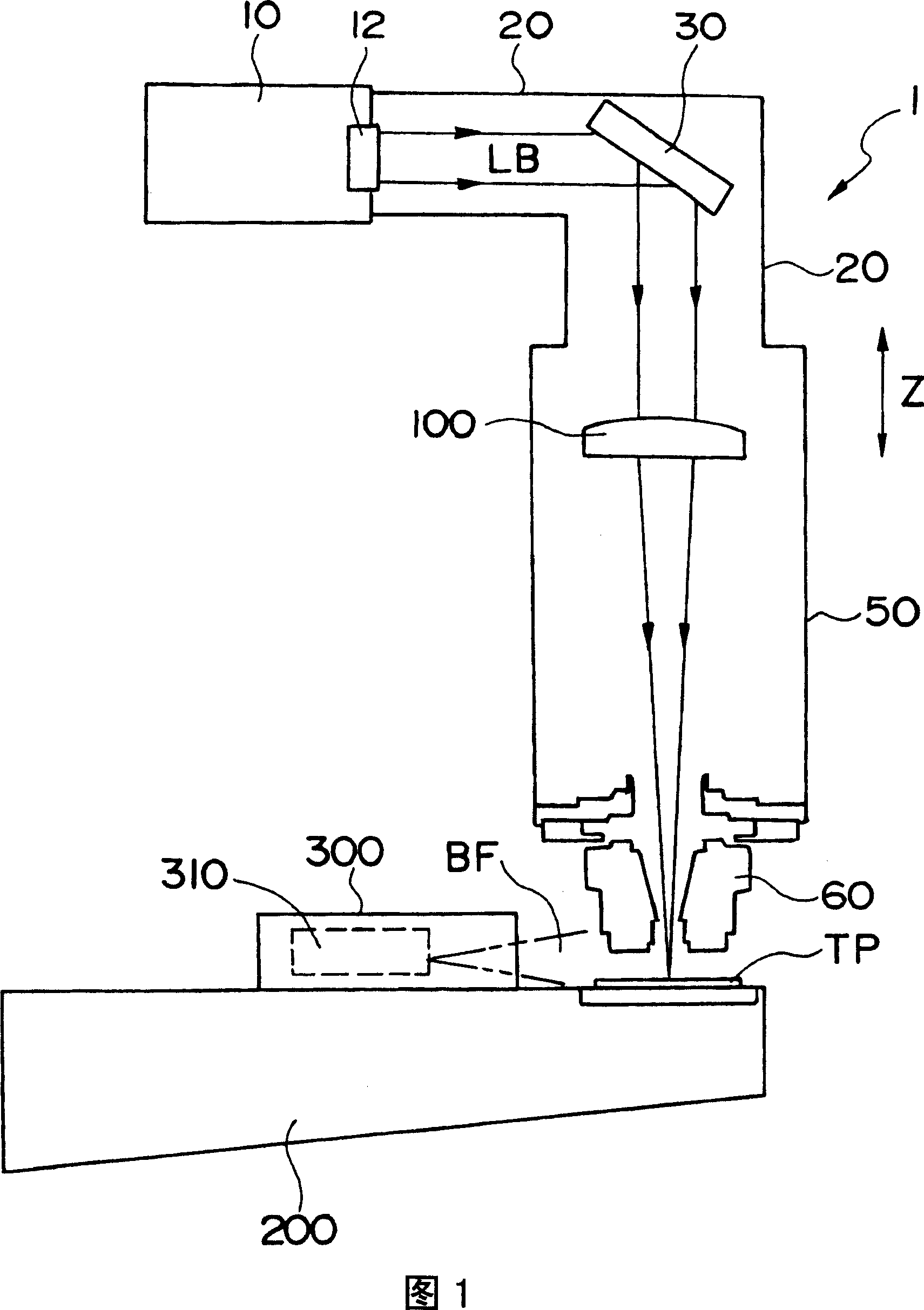

[0016] FIG. 1 is an explanatory view showing the overall configuration of a dirt detection device for a condenser lens of a laser processing machine according to the present invention.

[0017] Reference numeral 1 denotes an overall condenser lens dirt detection device, which includes a light receiving device 300 provided on a partial base 200 of the laser processing machine. This light-receiving device 300 has a light-receiving sensor 310 and detects a strong light called a blue flame BF that occurs when the focus positions of the laser beams condensed on the test piece TP coincide.

[0018] A laser resonator 10 of a laser processing machine outputs a laser beam LB to an optical path 20 through an output lens 12 . A turning mirror 30 and the like are arranged in the optical path 20 to guide the laser beam LB into the machining head 50 .

[0019] With respect to the optical path 20 on the fixed side, the laser head 50 is controlled to move in the Z-axis direction perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com