Laser nozzle device and method for uniformly distributing powder

A nozzle device and uniform distribution technology, applied in laser welding equipment, coating, metal material coating process, etc., can solve the problems of prolonging the powder feeding time, uniform powder feeding, and insufficient powder uniformity, so as to improve operability , reduce the overall size, reduce the effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

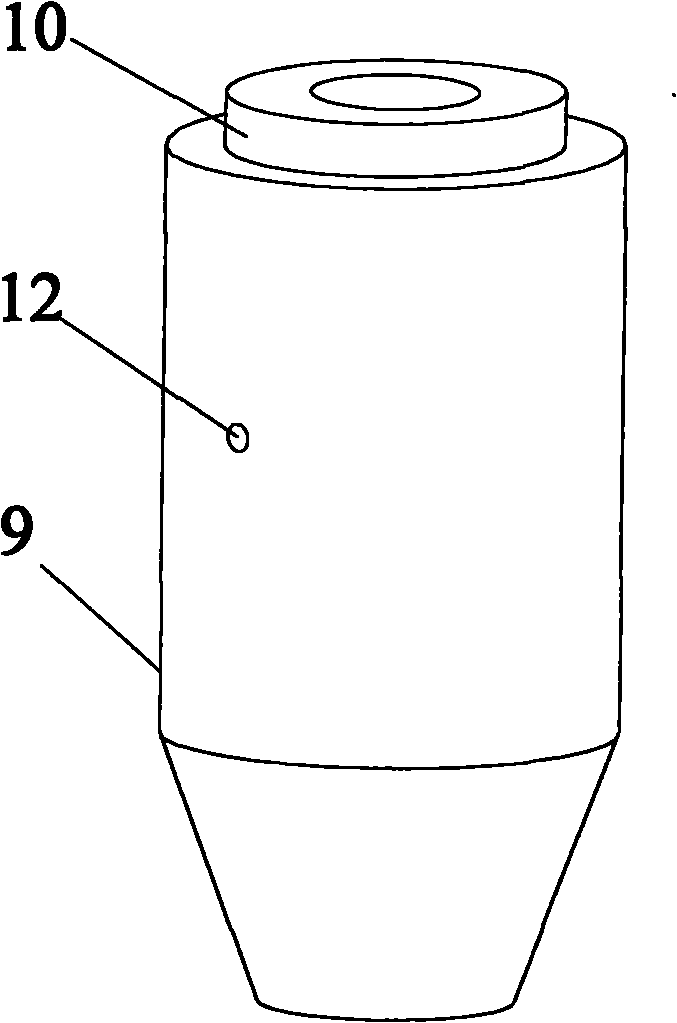

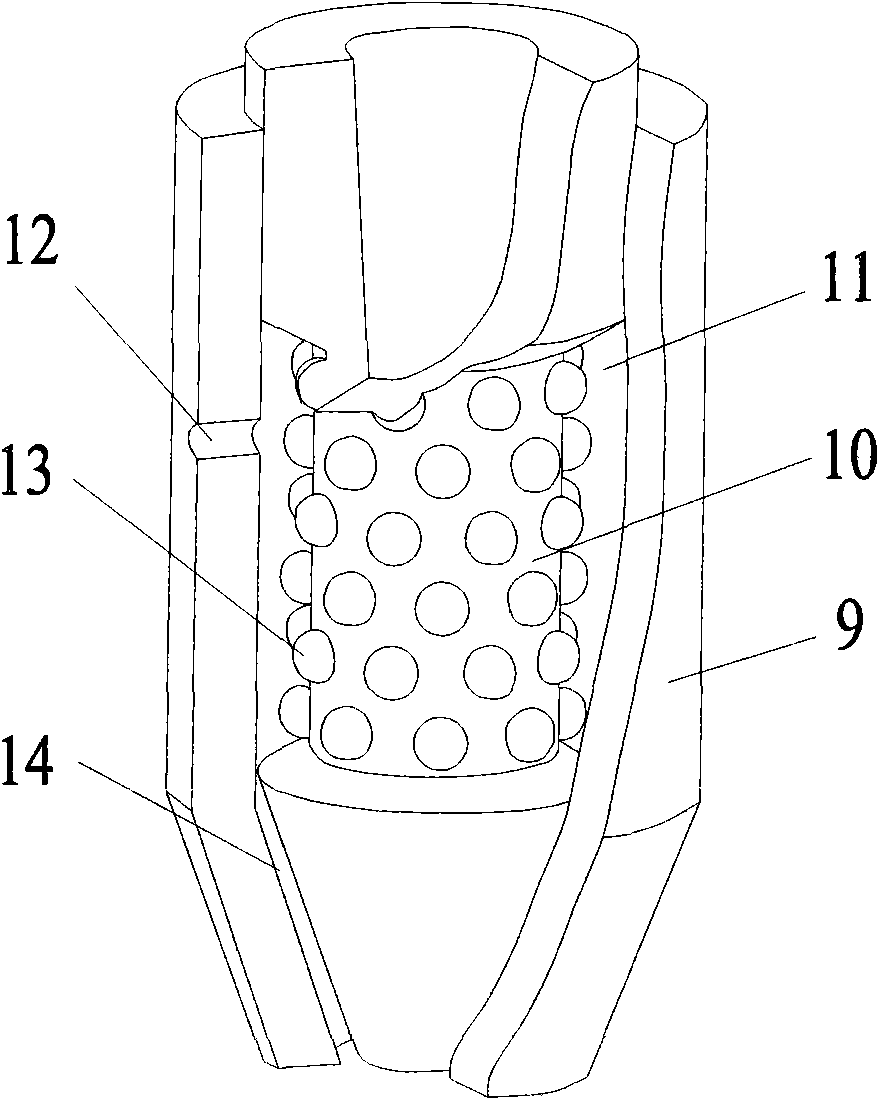

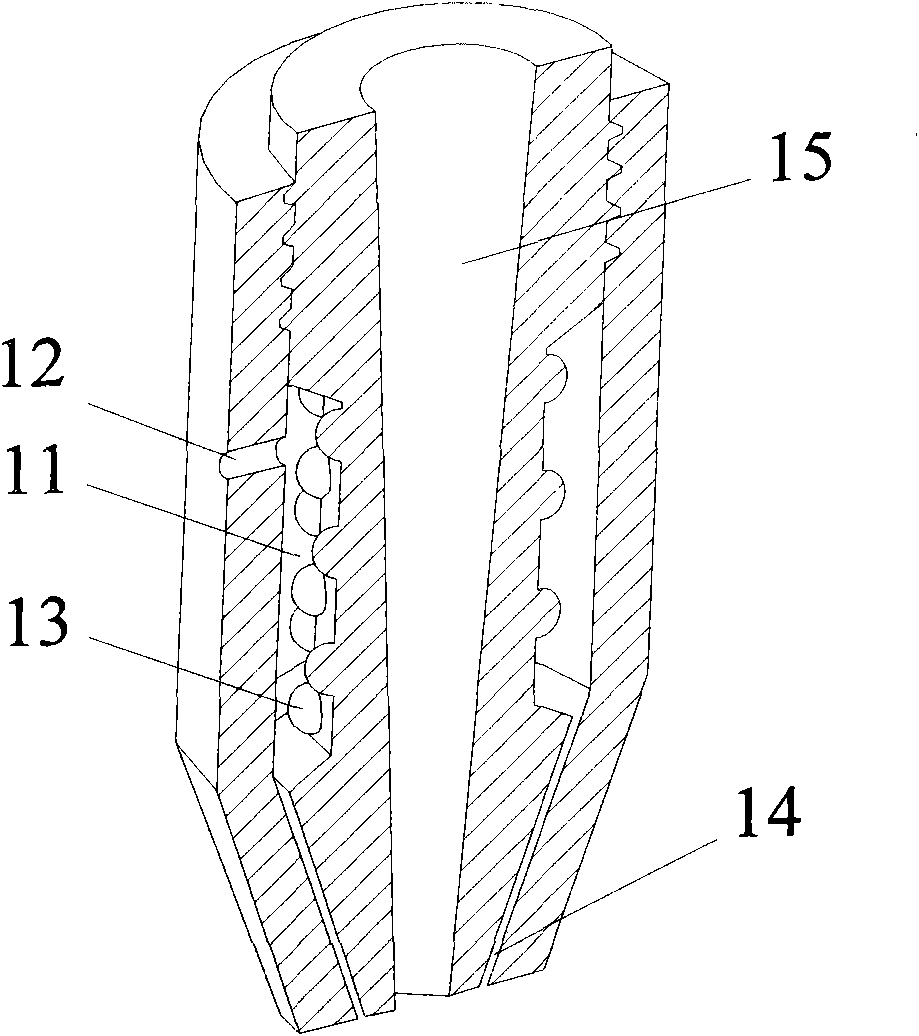

[0033] Figure 1 to Figure 5 shows the specific structure of this embodiment, such as figure 1 As shown, the laser nozzle device includes an outer casing 9 and a nozzle core 10 placed inside the outer casing 9, the side wall at the upper end of the outer casing 9 has a powder inlet 12, and the powder inlet 12 is externally connected to the powder inlet pipeline; figure 2 As shown, a powder outlet 14 is provided between the lower end of the jacket 9 and the lower end of the nozzle core 10; a powder channel 11 is provided between the inner side of the jacket 9 and the outer side of the nozzle core 10, and the powder channel 11 extends to the powder outlet 14 places, and the powder inlet 12, the powder channel 11, and the powder outlet 14 are connected to each other; as figure 2 As shown, the outer wall of the nozzle core 10 is inlaid with several steel balls 13, and the nozzle core 10 is provided with a laser channel 15, such as image 3 Shown; the upper end of the jacket 9 ...

Embodiment 2

[0047] This embodiment has the same structure as Embodiment 1 except the following features: the distance between the centers of the steel balls is 3 times the diameter of the steel balls, and the diameter of each steel ball is 2 mm.

[0048] There are 6 powder inlets, and each powder inlet is uniformly arranged around the central axis of the jacket.

[0049] The distance between the top end of the steel ball 13 facing the outer shell and the inner wall of the outer shell 9 is 5mm.

Embodiment 3

[0051] The structure of this embodiment is the same as that of Embodiment 1 except for the following features: the distance between the centers of the steel balls is twice the diameter of the steel balls, and the diameter of each steel ball is 1mm.

[0052] There are three powder inlets, and each powder inlet is uniformly arranged around the central axis of the jacket.

[0053] The distance between the top end of the steel ball 13 facing the outer shell and the inner wall of the outer shell 9 is 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com