Two-way weight-reducing track vehicle supporting device

A crawler and vehicle technology, which is applied in the field of tracked vehicle load support devices, can solve problems such as poor vibration tolerance and difficulty in meeting ride comfort requirements of the load support mechanism, and achieve cost reduction, reasonable force, and prevention of damage to the mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings:

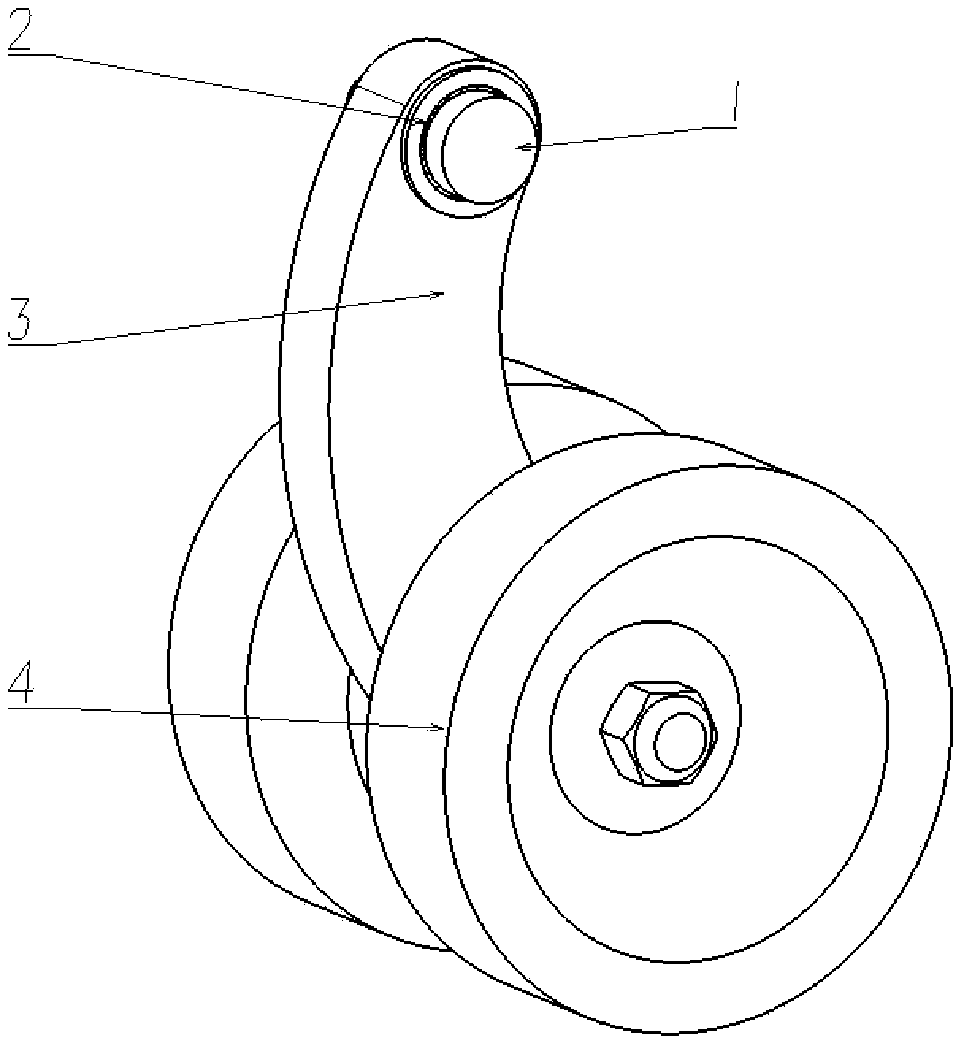

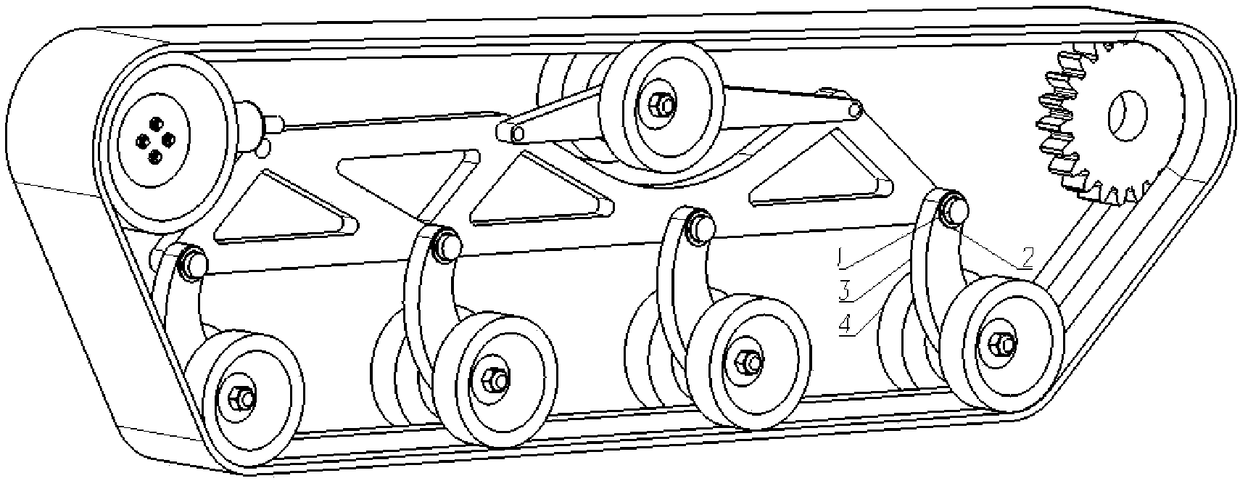

[0021] See figure 1 , A two-way weight reduction tracked vehicle weight support device, its components mainly include hinge support 1, torsion shock absorber 2, swing arm 3, support wheel 4 and so on. Among them, the hinge support 1 is fixedly connected to the trolley frame (or walking system bracket), the torsion damper 2 is installed between the hinge support 1 and the swing arm 3, and the other end of the swing arm 3 is equipped with a supporting wheel 4 through a bearing.

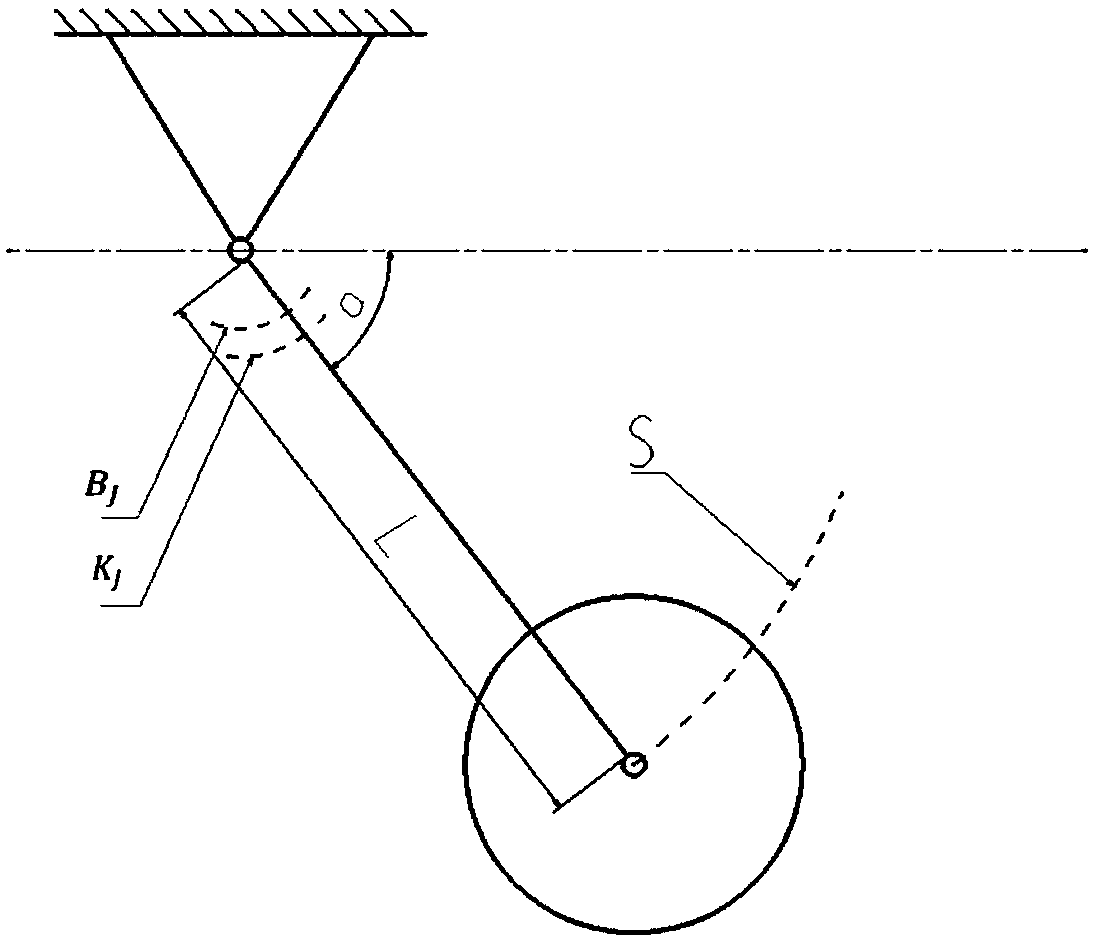

[0022] See figure 2 , To describe the basic principle of the present invention, the hinge support 1 is fixed on the trolley frame (or walking system bracket), the swing arm 3 swings around the hinge point on the hinge support; the supporting wheel 4 is installed at the other end of the swing arm ; The crawler is in contact with the supporting wheels 4 to transmit the input from the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com