An automatic flaw detection device for the surface of an aircraft hub

A flaw detection device, aircraft wheel technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of low detection efficiency, achieve the effect of improving detection efficiency and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-6 The application is described in further detail.

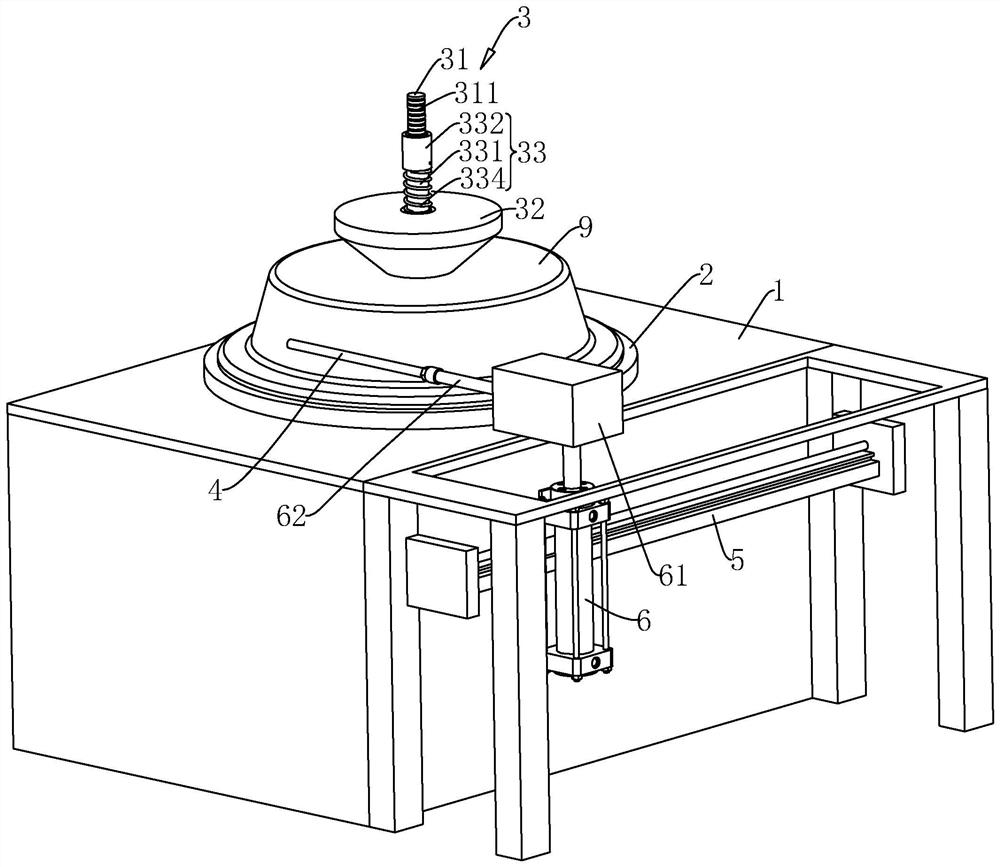

[0040] The embodiment of the present application discloses an automatic flaw detection device for the surface of an aircraft hub. refer to figure 1 , the flaw detection device includes a mount 1, a turntable 2 rotatably connected to the mount 1 for placing the aircraft hub 9, a limit device 3 for fixing the position of the aircraft hub 9 on the turntable 2, and a flaw detection device for the aircraft hub 9. Probe 4. When in use, directly place the aircraft hub 9 to be inspected on the turntable 2, fix the position of the aircraft hub 9 on the turntable 2 by the limiting device 3, and perform flaw detection on the surface of the aircraft hub 9 through the probe 4.

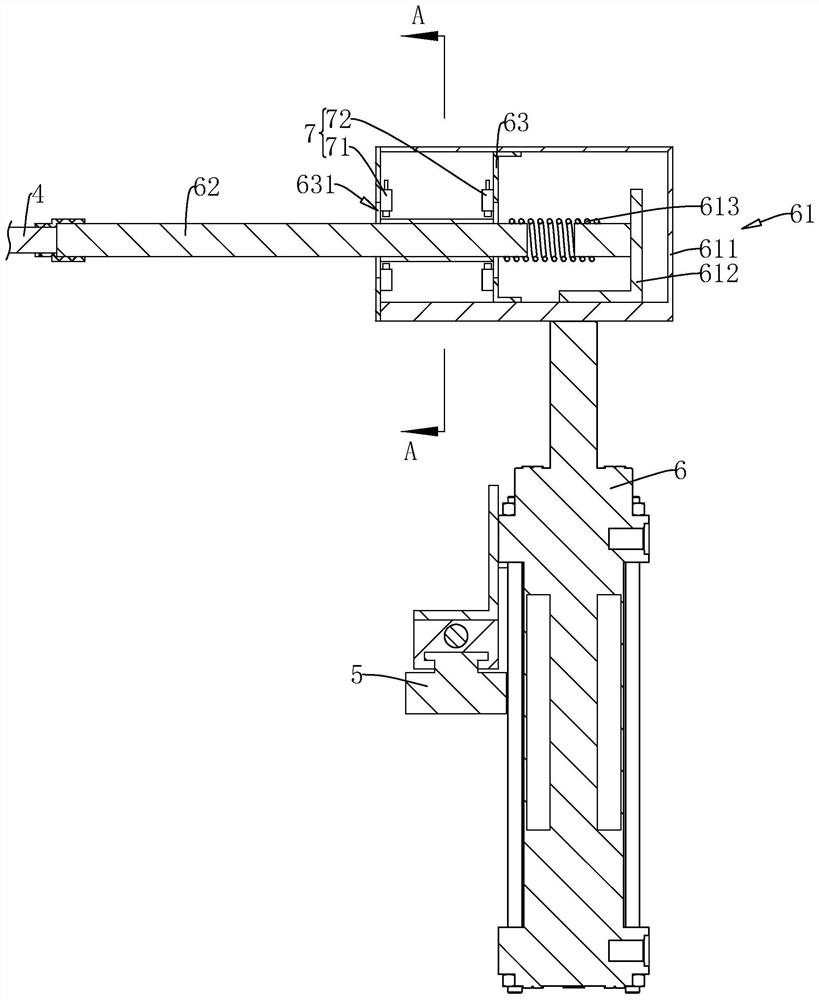

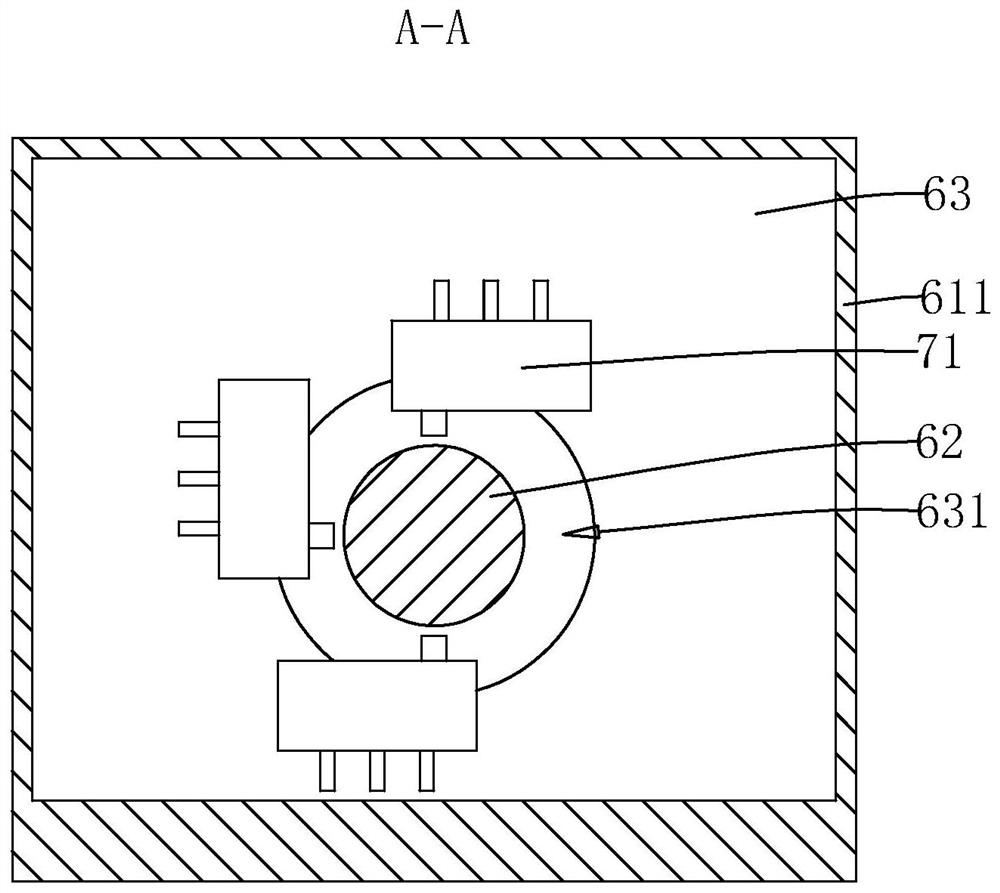

[0041] Wherein, the mounting base 1 is also provided with a horizontal driver 5 that drives the probe 4 to approach the direction of the aircraft hub 9 and a vertical driver fixed on the horizontal driver 5 for driving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com