Programmable control flexible actuator and preparation method thereof

An actuator and flexible technology, which is applied in the field of programmable manipulation of flexible actuators and their preparation, and can solve problems such as the fixed motion law of flexible double-layer membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

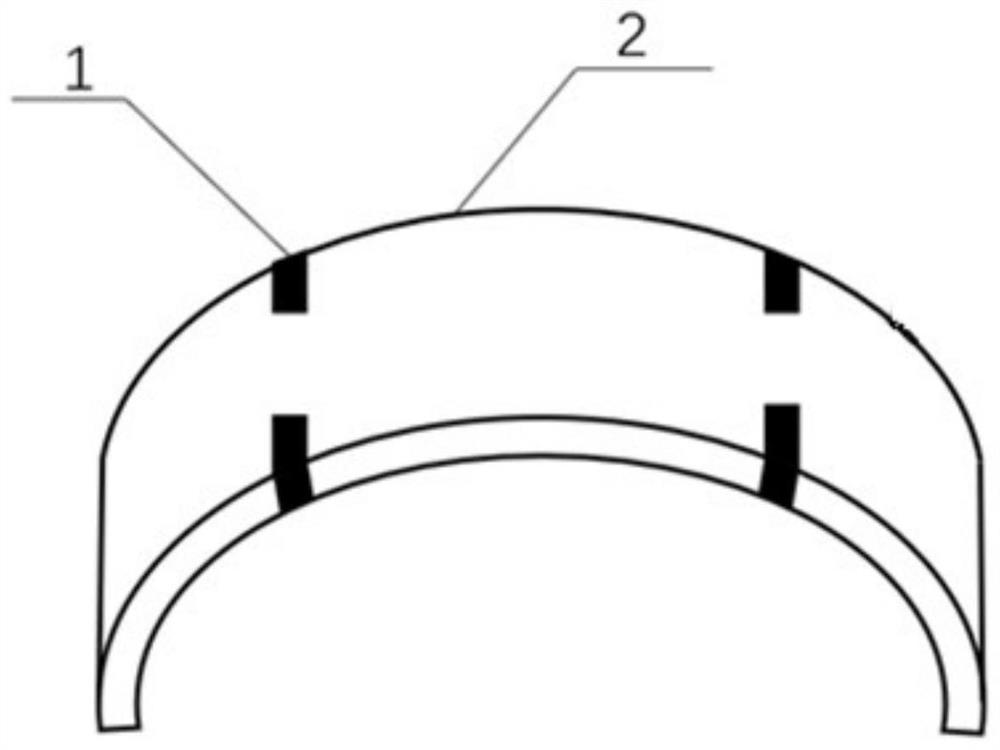

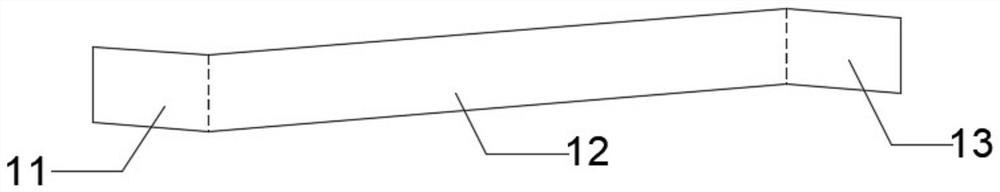

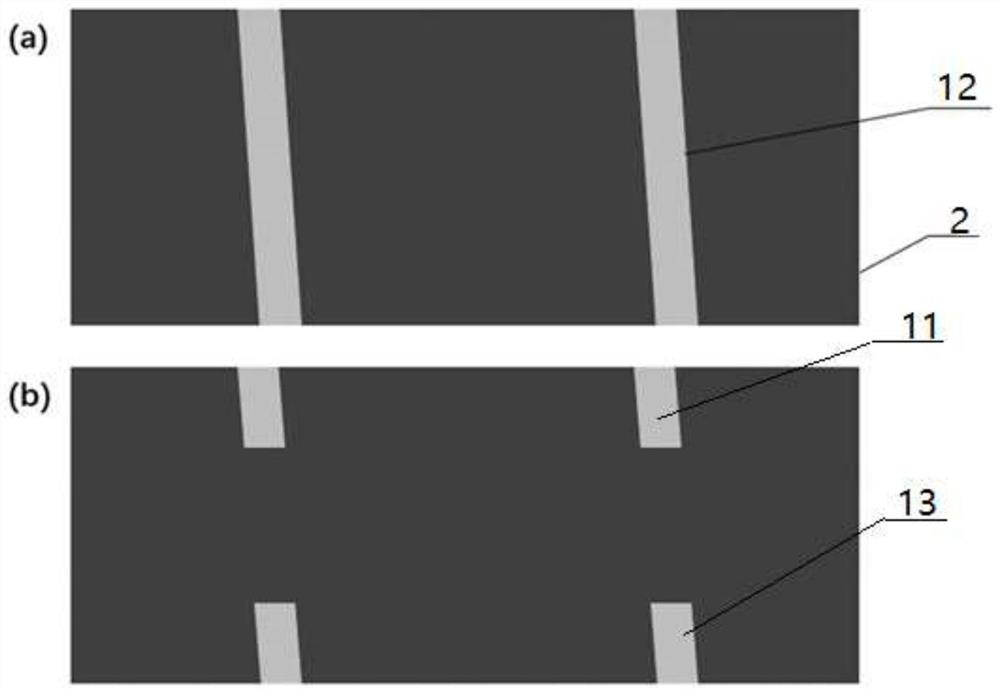

[0049] see figure 1 , this embodiment introduces a programmable manipulation flexible actuator, which includes a flexible double-layer membrane 2 and a clamping foil 1 .

[0050] Wherein, during the production process, the flexible double-layer film 2 is elongated when heated, and arched when naturally cooled. The flexible double-layer film includes a laminated strip-shaped polydimethylsiloxane layer and a carbon nanotube layer, and the carbon nanotube layer is located on the side protruding outward in the arched structure; the polydimethylsiloxane layer The methyl silicone layer is on the concave side of the arch.

[0051] There are two sets of sandwiched foils 1, and they are in the form of strips. The clamping foil 1 is used to clamp the assembly of the flexible double-layer film 2 . The two groups of sandwiching foils 1 are wound from one side of the carbon nanotube layer, pass through the polydimethylsiloxane layer, and reach the other side of the carbon nanotube layer...

Embodiment 2

[0066] see Figure 5 , this embodiment introduces a flexible actuator manipulating device, which is used to operate the flexible actuator in the programmed manipulation flexible actuator introduced in Embodiment 1. The flexible actuator manipulator includes an illuminating element.

[0067] The longer side of the strip-shaped flexible double-layer film is defined as the long side, and the shorter side is the short side; the irradiation element irradiates the carbon nanotube layer of the flexible double-layer film, and its light is The central part of the long side is irradiated from one end to the other to drive the flexible bilayer membrane to crawl. The optical fiber passes through the two clamping foils 1 in sequence. The irradiation element adopts a near-infrared laser 3, and the radiation distance of the near-infrared laser 3 is 10 cm, and the power is 200 mW.

[0068] In this embodiment, when the radiation distance of the near-infrared laser 3 and the power of the lig...

Embodiment 3

[0070] see Image 6 , this embodiment introduces a method for preparing a programmable and manipulable flexible actuator, which is used to prepare a programmable and manipulable flexible actuator introduced in Embodiment 1. When preparing the programmable manipulative flexible actuator, the flexible double-layer film 2 and the clamping foil 1 need to be prepared separately.

[0071] Wherein, the preparation method of flexible double-layer film 2 comprises steps:

[0072] Step S1, evaporating the carbon nanotube suspension on the substrate to obtain a solidified carbon nanotube layer. Wherein, the substrate may be a glass substrate or a substrate of other materials, as long as it can support the suspension of carbon nanotubes.

[0073] Step S2, spreading the viscous polydimethylsiloxane mixture evenly on the carbon nanotube layer, and curing at 100° C. to obtain a double-layer film. Wherein, after the viscous polydimethylsiloxane mixture is evenly applied on the carbon nanot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com