Adjustable magnetic field coupling and ultrasonic-assisted laser additive manufacturing and monitoring device

A laser additive and ultrasonic-assisted technology, applied in the direction of manufacturing tools, laser welding equipment, welding equipment, etc., can solve problems such as splashing, flare molten pool surface disturbance, affecting manufacturing quality and efficiency, and difficult molten pool morphology, etc., to achieve Improve the monitoring environment, weaken the shielding effect, and achieve better mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

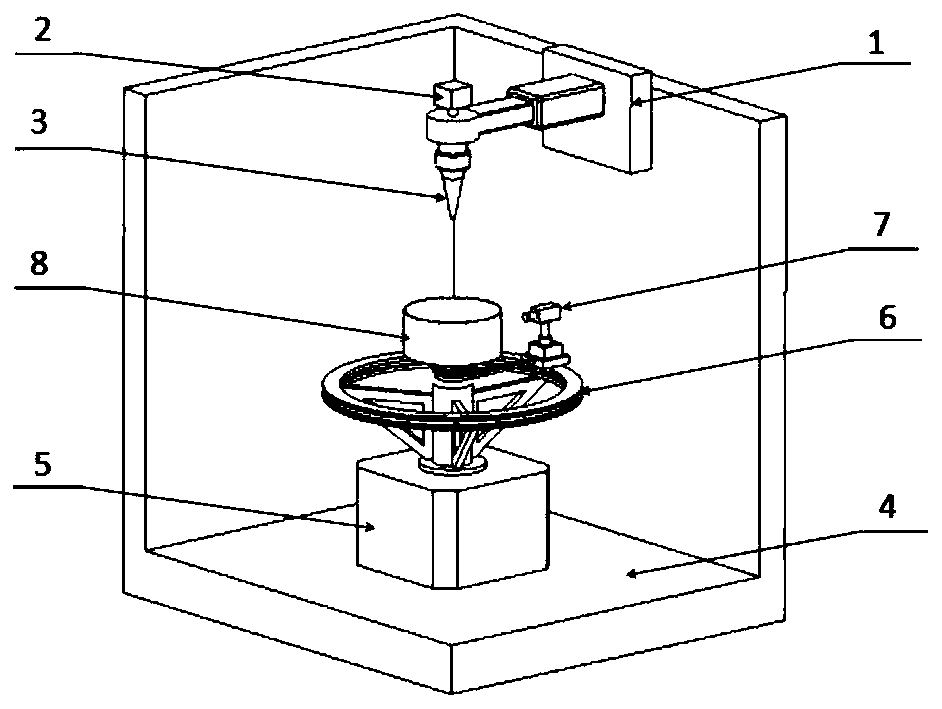

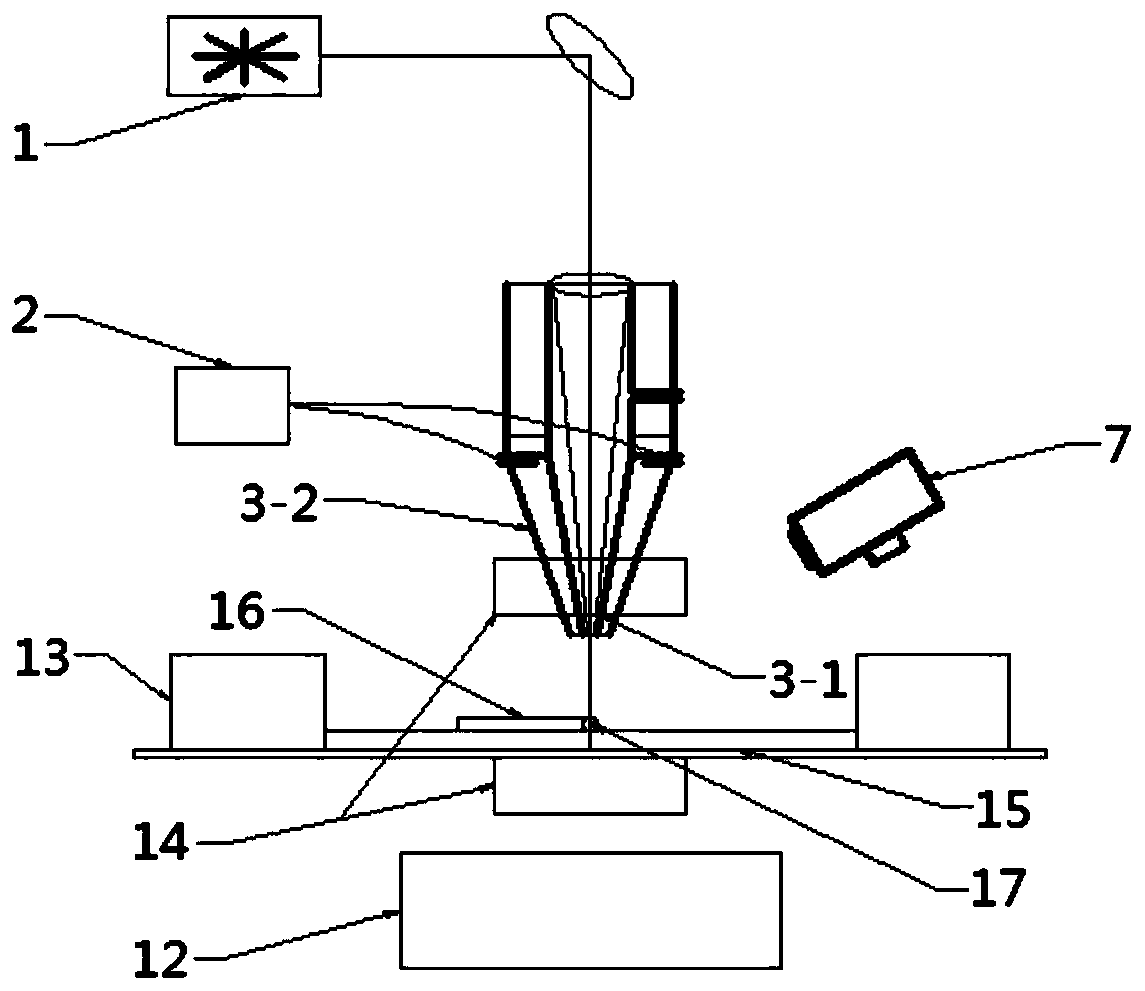

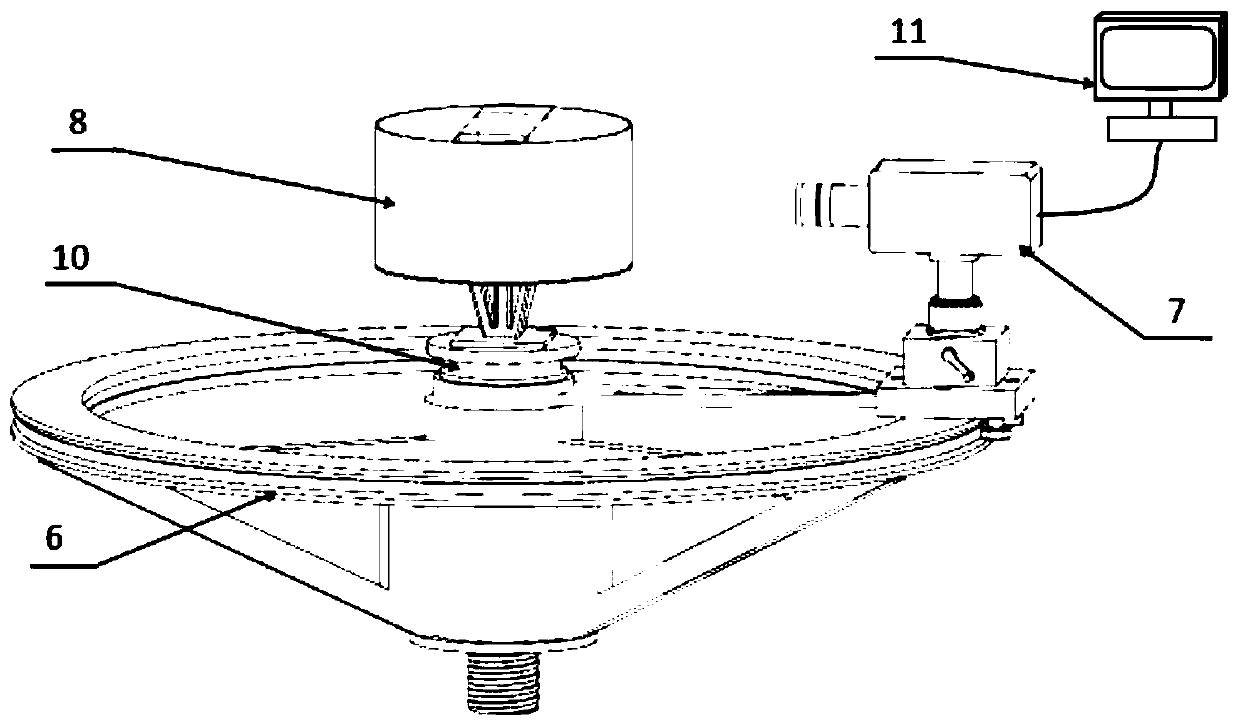

[0028] like figure 1 and figure 2 As shown, the adjustable magnetic field coupling ultrasonic-assisted laser additive manufacturing and monitoring device of the present invention includes a laser additive manufacturing system, a substrate 15, a magnetic field coupling auxiliary device, an ultrasonic auxiliary unit 12 and a monitoring device; a laser additive manufacturing system Including fiber laser 1, powder feeder 2, laser head 3, machine base 4 and workbench 5, the laser beam generated by fiber laser 1 is focused by the optical system to form a high-energy laser beam and irradiates the predetermined position of the substrate 15, while the laser nozzle 3- 1 Blow out the protective gas, the powder feeder 2 is connected with the coaxial powder feeding nozzle 3-2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com