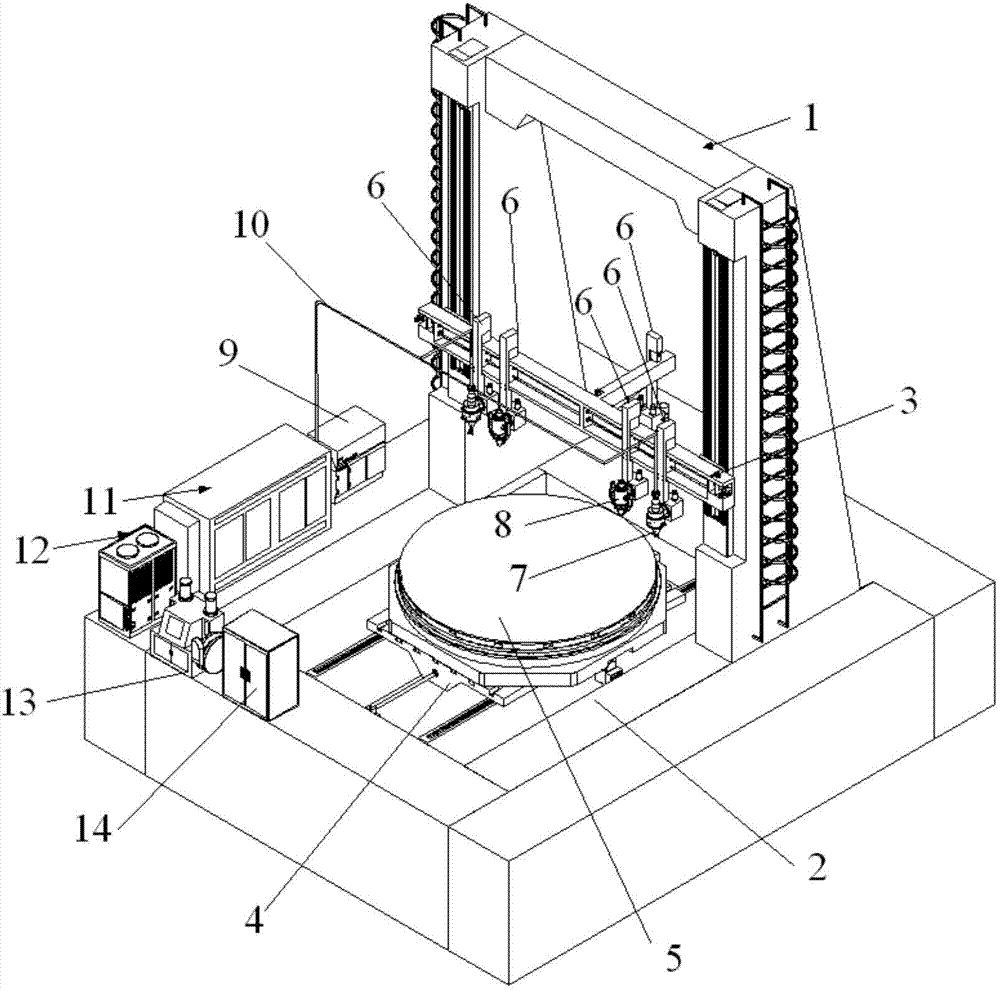

Nuclear heavy blank molding process and LCD-EBAM integrated printing equipment

A molding process and 3D printing technology, applied in the improvement of process efficiency, metal material coating process, coating and other directions, can solve the problem of inability to achieve high efficiency, and achieve the effect of reducing energy consumption, ensuring molding accuracy, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: a kind of nuclear power heavy-duty blank forming process, the specific steps are as follows:

[0025] Step 1: Import the 3D model STL file of the blank into the forming software program, perform layered processing, select the best forming direction, divide each main forming process (cylindrical part, connecting boss part, spherical shell part), add necessary support structures;

[0026] Step 2: Run the laser nozzle 7 and the electron beam gun 8 to the preset coordinate origin;

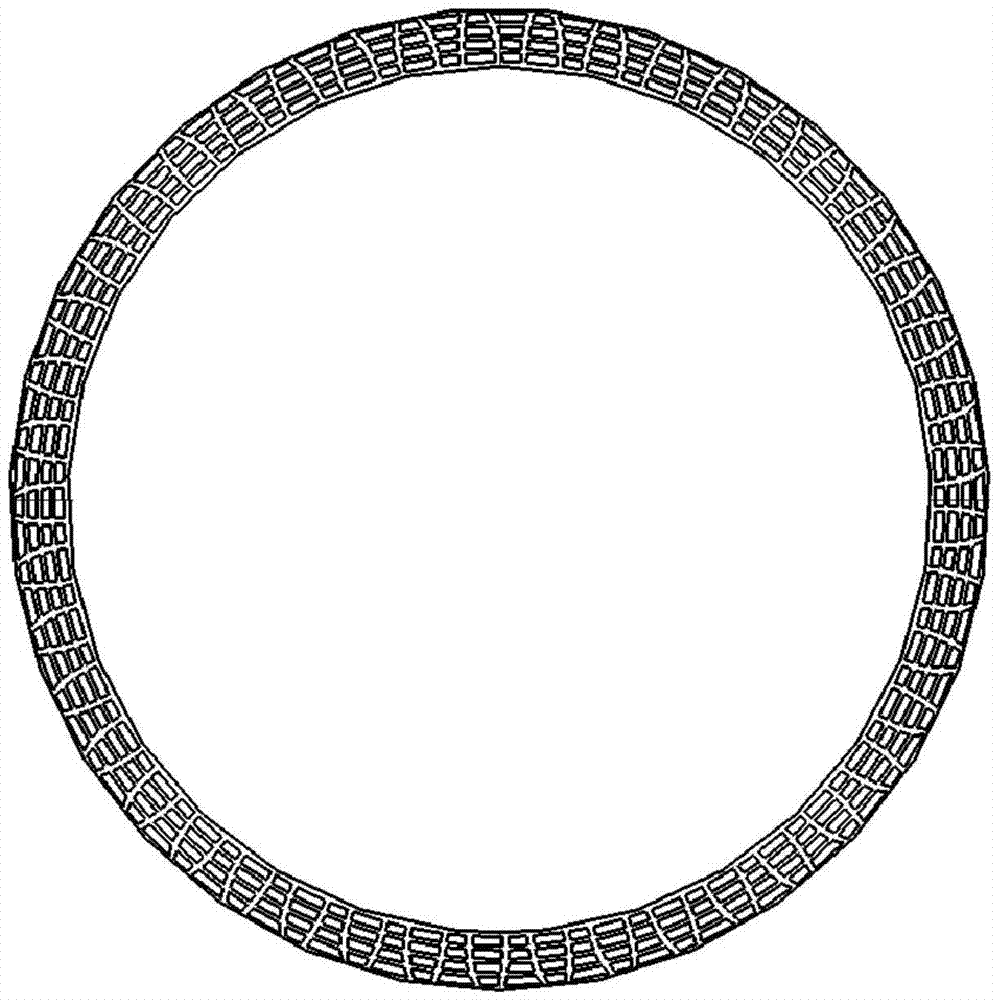

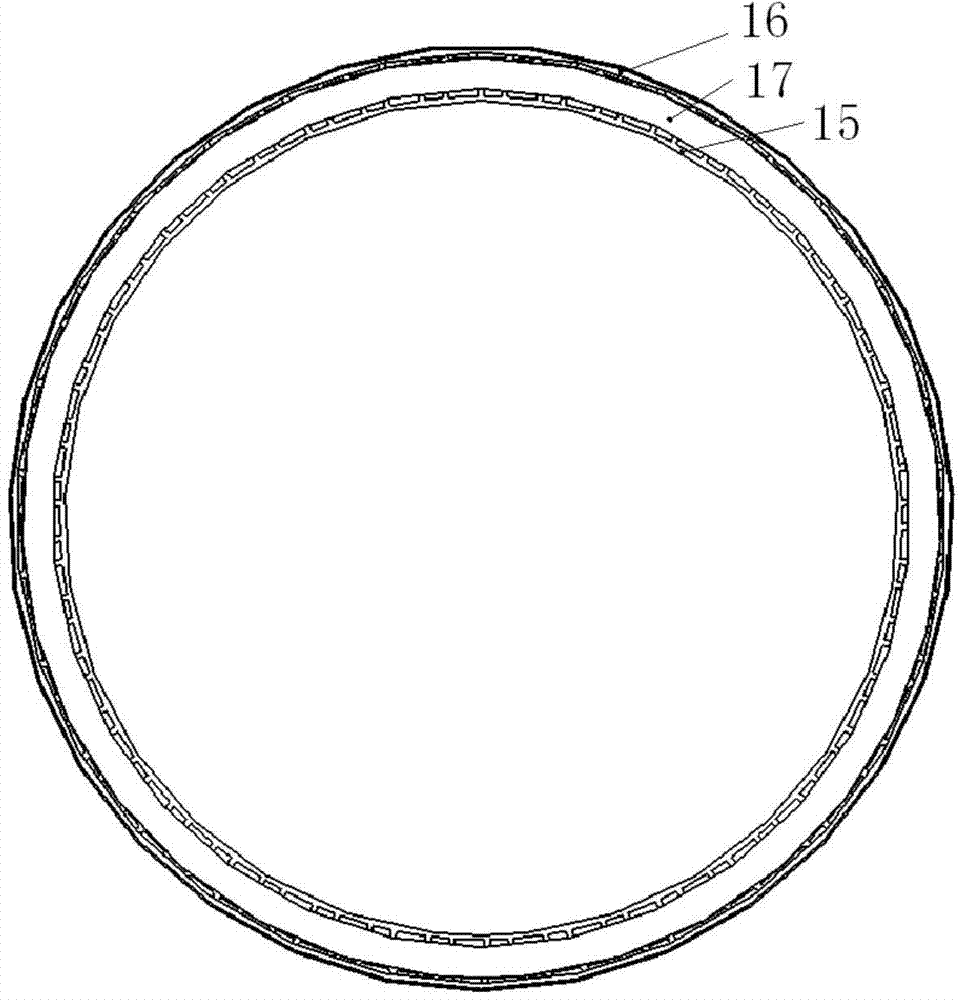

[0027] Step 3: Forming of the ring support 15: start the rotary table 5 and maintain a certain speed, and the main laser nozzle 7 (which can be a laser nozzle 7 or an electron beam gun 8) cladding a stainless steel ring support 15 on the surface of the rotary table 5 , then the main laser nozzle 7 moves one step along the movable beam 3 away from the center of the rotary table 5, and then turns on the main laser nozzle 7 to clad a concentric annular support 15, and repeat the claddi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com