Continuous pattern type powder coating with flashing effect as well as preparation method and application thereof

A powder coating and cotton technology, which is applied in the field of powder coatings, achieves the effects of simple and easy preparation method and application, easy implementation and expansion of application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

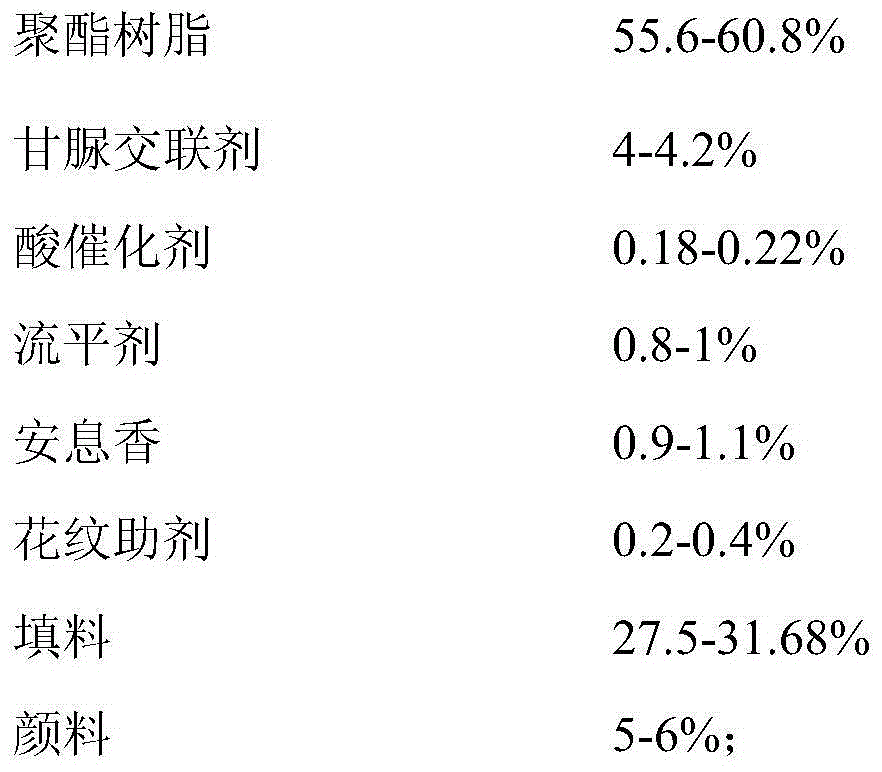

[0027] The base powder of the moire type powder coating with flashing effect is made of the following raw materials in mass percentage:

[0028]

[0029] The above raw materials are mixed evenly, melted and extruded by an extruder, tableted, air-cooled, milled, and sieved to obtain a mosaic-patterned powder coating base powder with a glittering effect.

[0030] Add aluminum powder YM2065, according to 0.8% of the total mass of the primer, to the moire-type powder coating primer with flashing effect, bond at 60°C, and set the bonding time to 12 minutes, to obtain a moire-type powder coating with a shimmering effect powder coating.

[0031] The moire-patterned powder coating with sparkling effect prepared in this example was heated and cured in an electric blast drying oven, the curing temperature was 200° C., and the curing time was 12 minutes.

[0032] The performance test results of the obtained coating film after curing are shown in Table 1:

[0033] Table 1 Example 1 P...

Embodiment 2

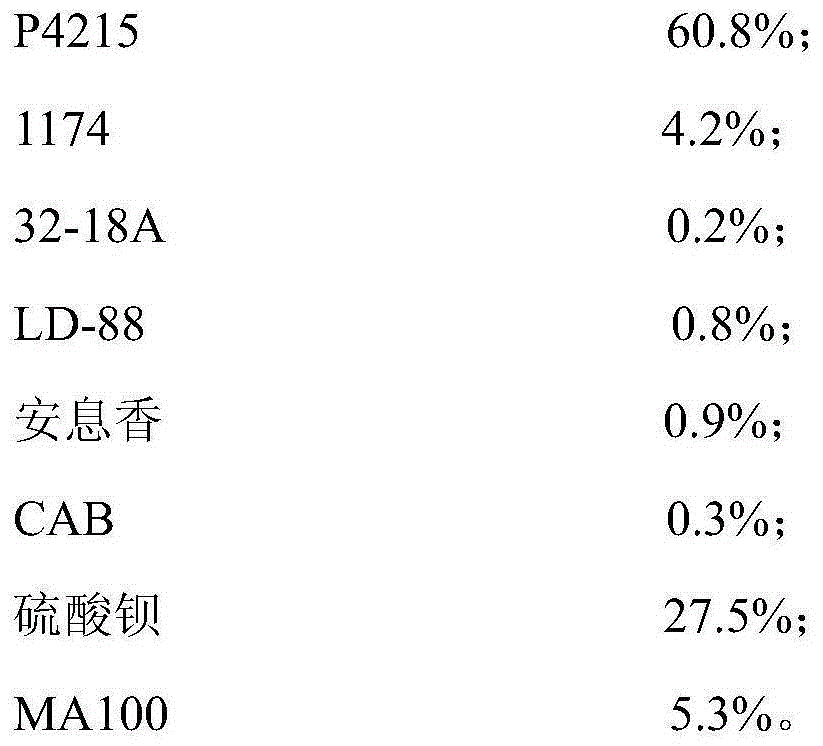

[0036] The base powder of the moire type powder coating with flashing effect is made of the following raw materials in mass percentage:

[0037]

[0038]

[0039] According to the process described in Example 1, the moire type powder coating with glittering effect was prepared, the difference being that: the aluminum powder YM2065 was added according to 0.7% of the total mass of the primer, the bonding temperature was 62°C, and the bonding time was set to 10 minutes.

[0040] The curing temperature is 210° C., and the curing time is 10 minutes.

[0041] The performance test results of the obtained coating film after curing are shown in Table 2:

[0042] Table 2 embodiment 2 performance testing result

[0043]

Embodiment 3

[0045] The base powder of the moire type powder coating with flashing effect is made of the following raw materials in mass percentage:

[0046]

[0047]

[0048] According to the process described in Example 1, the moire type powder coating with glittering effect was prepared, the difference was that: aluminum powder YM2065 was added according to 0.6% of the total mass of the primer, the bonding temperature was 58°C, and the bonding time was set to 15 minutes.

[0049] The curing temperature is 220°C, and the curing time is 8 minutes.

[0050] The performance test results of the obtained coating film after curing are shown in Table 3:

[0051] Table 3 Example 3 Coating film performance detection result

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com