Mesh fluid texture type damping bearing

A damping bearing and mesh technology, applied in bearings, flexible bearings, bearing components, etc., can solve the problems of water-lubricated stern bearing vibration and noise reduction application gaps, etc., to improve comfort and concealment of underwater vehicles, The effect of reducing relative friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

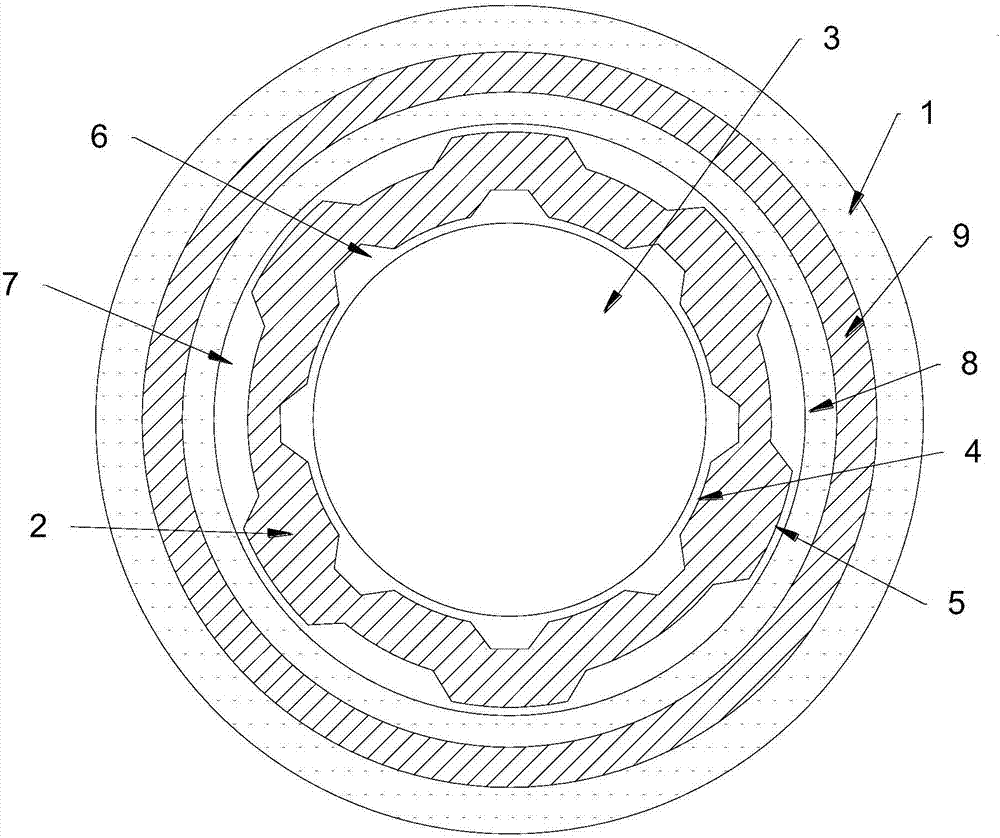

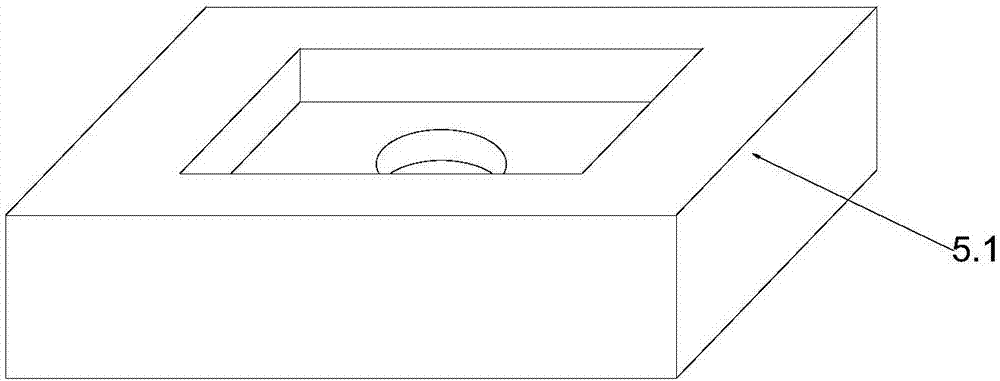

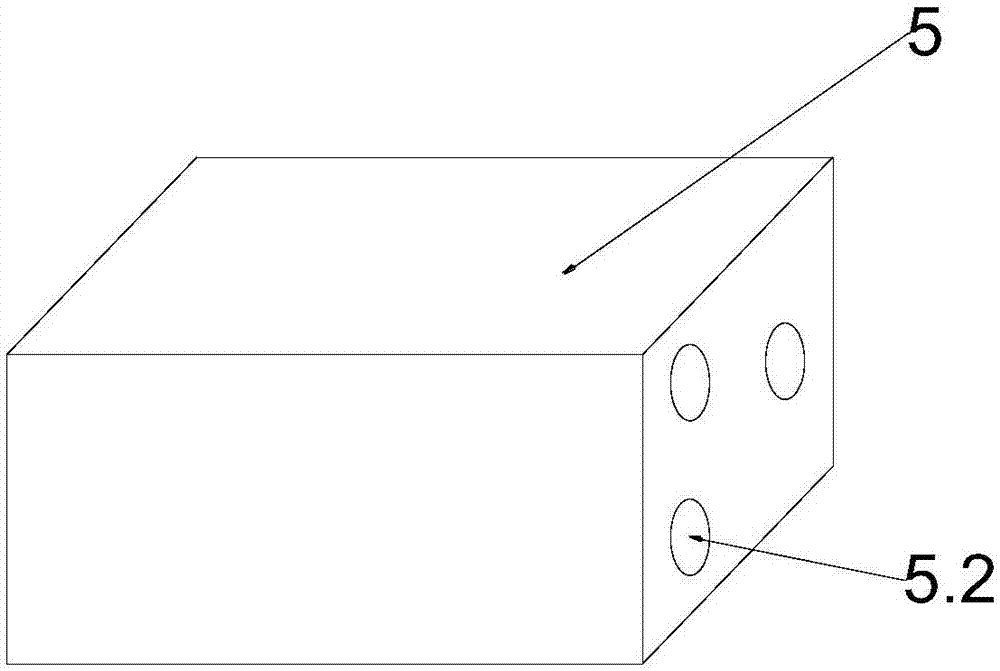

[0025] Such as Figure 1~4 , a mesh fluid texture damping bearing, including a metal outer ring 1, a rubber body 2 and a main shaft 3, the rubber body 2 is sleeved in the metal outer ring 1, and the main shaft 3 is sleeved in the rubber body 2 , the inner and outer layers of the rubber body 2 are arranged with axially distributed inner rubber slats 4 and outer rubber slats 5, the adjacent slats of the inner rubber slats 4 are provided with inner water tanks 6, and the outer rubber slats The adjacent slats of 5 are provided with an outer water tank 7, and the inner water tank 6 and the outer water tank 7 are respectively connected with the external hydraulic system. The surfaces of the inner rubber slats 4 and the outer rubber slats 5 are provided with composite textures 5.1. The inner rubber slats 5 are axially provided with mesh holes 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com