Building and application method for functional tobacco module

A technology of module construction and application method, which is applied in the fields of application, tobacco, preparation of tobacco, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

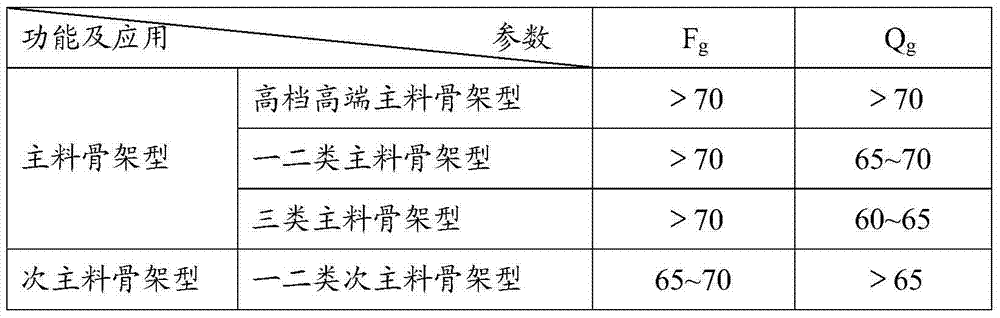

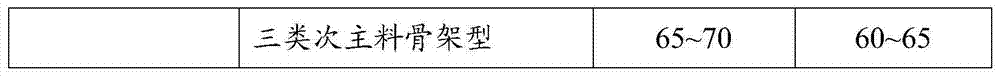

[0050] A specific implementation of the construction and application method of a functional tobacco leaf module. The construction of the skeleton tobacco leaf module is mainly composed of typical skeleton tobacco leaves (as shown in Table 4). The internal chemical composition content of the skeleton-type tobacco leaf module constructed by testing (as shown in Table 5) was substituted into the skeleton-type functional parameter prediction model, and the application classification of the skeleton-type tobacco leaf module was determined according to Table 1. The results are shown in Table 6. The constructed skeleton-type tobacco leaf The sensory characteristics and application effects of the module are shown in Table 7.

[0051] Table 4 Construction of skeleton tobacco leaf modules

[0052]

[0053] Table 5 Model chemical index values of skeleton tobacco leaf module G1 and module G2

[0054]

[0055]

[0056] Table 6 Functional parameters, quality parameters and class...

Embodiment 2

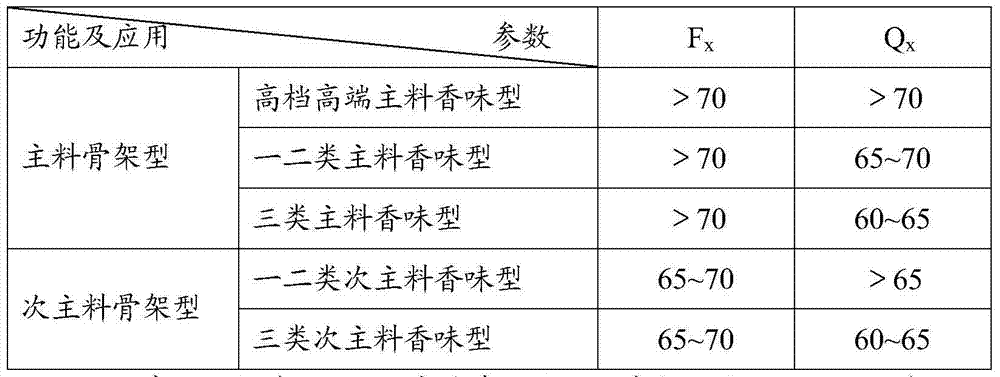

[0061] A specific implementation of the construction and application method of a functional tobacco leaf module. The construction of the flavor tobacco leaf module is mainly composed of typical flavor tobacco leaves (see Table 8). The internal chemical composition content of the flavored tobacco leaf module constructed by testing (as shown in Table 9) was substituted into the flavor type functional parameter prediction model, and the application classification of the flavored tobacco leaf module was determined according to Table 2. The results are shown in Table 10. The sensory properties and application effects of the constructed flavor-type tobacco leaf module are shown in Table 11.

[0062] Table 8 Flavored tobacco leaf module construction

[0063]

[0064] Table 9 Model chemical index values of flavor tobacco leaf module X1 and module X2

[0065]

[0066] Table 10 Functional parameters, quality parameters and classification applications of flavor-type tobacco leaf...

Embodiment 3

[0072] A specific implementation of the construction and application method of a functional tobacco leaf module. The construction of the textured tobacco leaf module is mainly composed of typical textured tobacco leaves (see Table 12). The internal chemical composition content of the texture-type tobacco leaf module constructed by testing (as shown in Table 13) was substituted into the texture-type functional parameter prediction model, and the application classification of the texture-type tobacco leaf module was determined according to Table 3. The results are shown in Table 14. The sensory properties and application effects of the constructed textured tobacco leaf module are shown in Table 15.

[0073] Table 12 Construction of Texture Tobacco Leaf Modules

[0074]

[0075]

[0076] Table 13 Model chemical index values of textured tobacco leaf module Z1 and module Z2

[0077]

[0078] Table 14 Functional parameters, quality parameters and classification applicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com