Production process of vamp screen cloth

A technology for making crafts and shoe uppers, applied in footwear, apparel, textiles and papermaking, etc., can solve the problems of complex craftsmanship and high production costs, and achieve the effects of simple craftsmanship, low cost, and increased diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described below in conjunction with specific embodiments:

[0030] The manufacturing process of the upper mesh cloth provided by the present embodiment comprises the following steps:

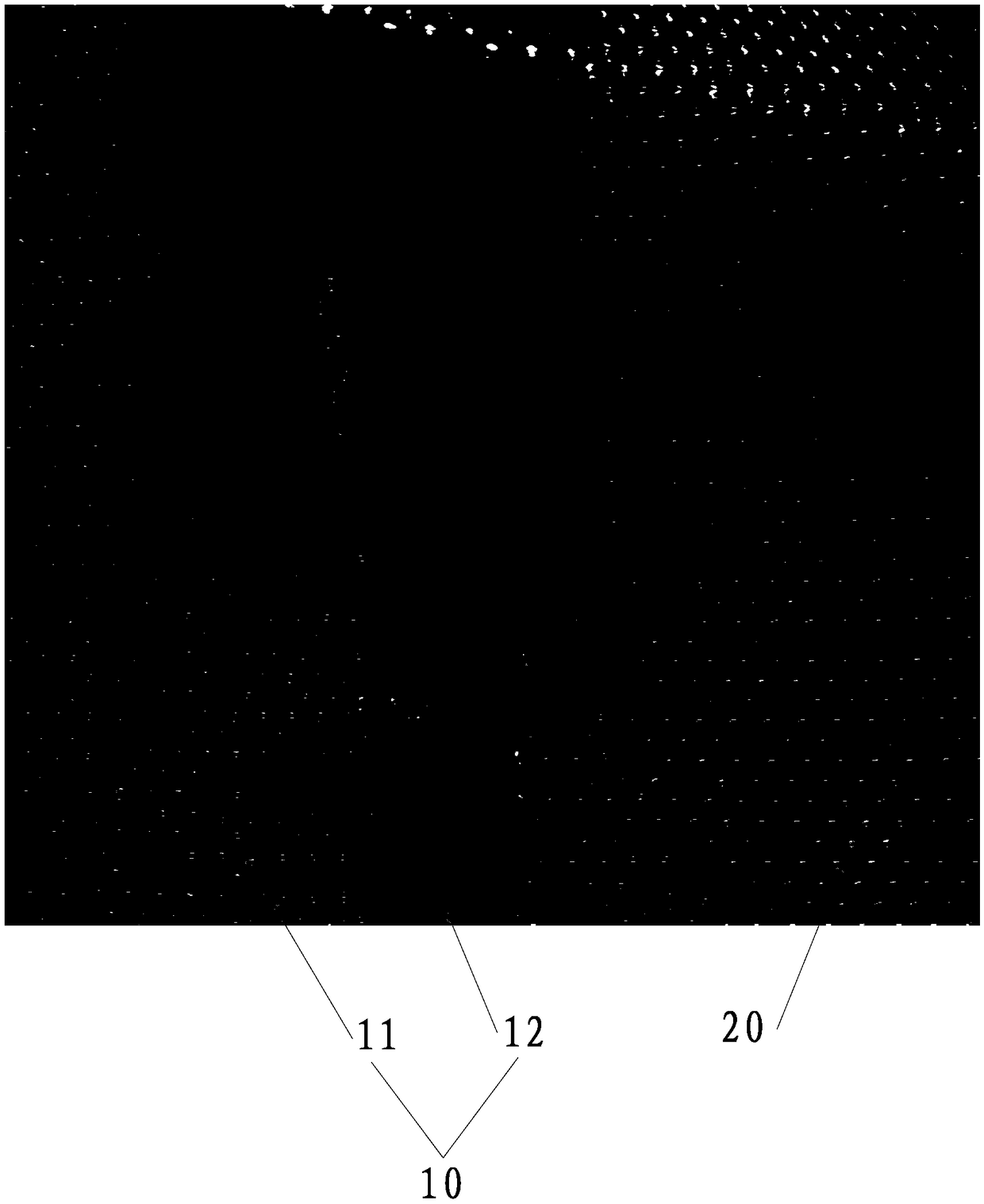

[0031] S1, preparation for weaving, reference figure 1 As shown, the upper area 10 and the non-upper area 20 of the mesh are designed on the computer, wherein the upper area 10 includes a thick area 11 and a hollow area 12, through the thick area 11 and the hollow area 12 on the upper area 10 The design of the shape and position forms the pattern of the vamp, and the specific pattern can be designed according to actual needs. It should be noted that the thick and hollow in the thick region 11 and the hollow region 12 are just names, and do not mean that the corresponding region is thicker than other regions or that the corresponding region has a hollow structure.

[0032] S2, bar configuration, select a single-needle bed warp knitting machine with more than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com