Textured columbate leadless piezoelectric materials and method for making same

A lead-free piezoelectric and niobate technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve problems such as difficulty in achieving densification and sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

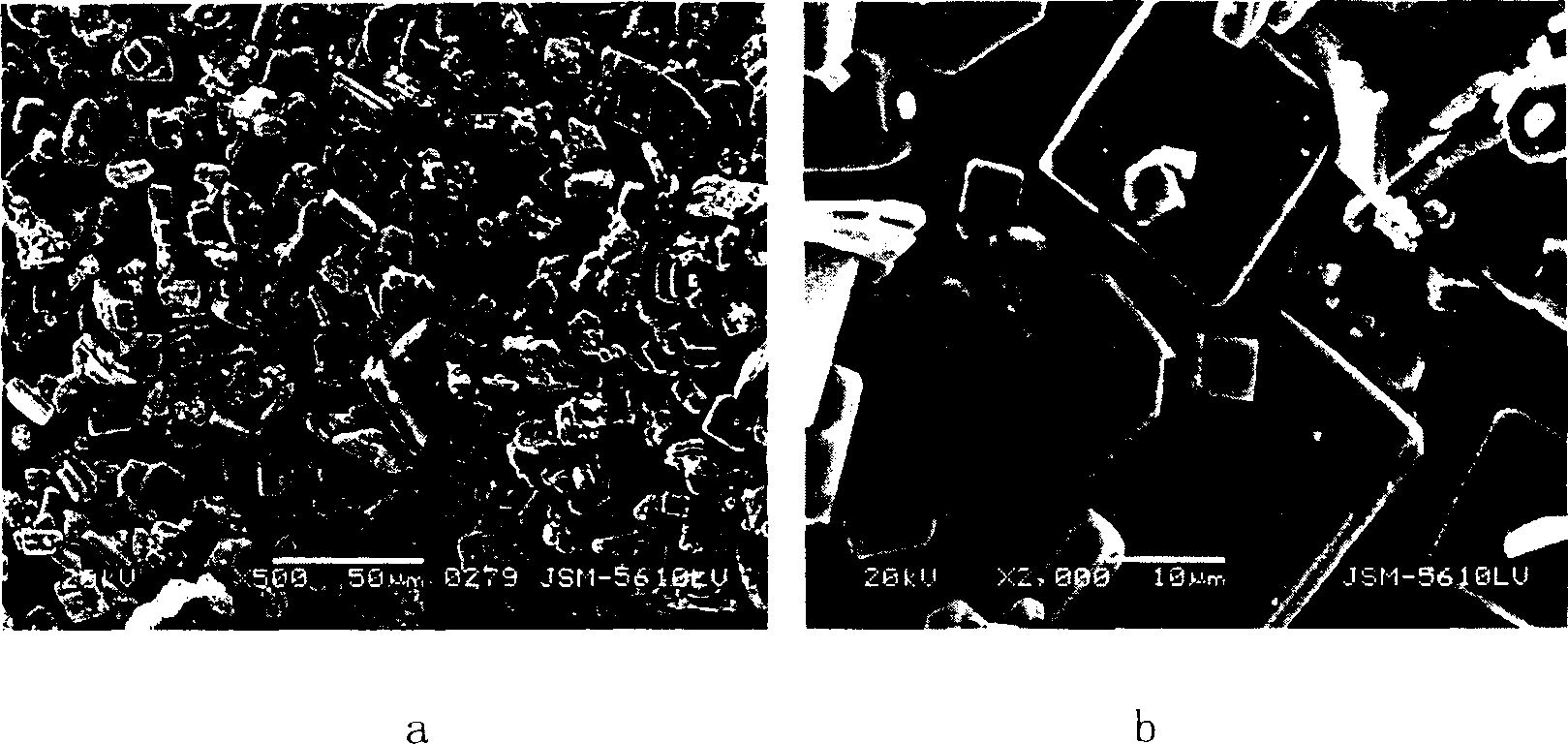

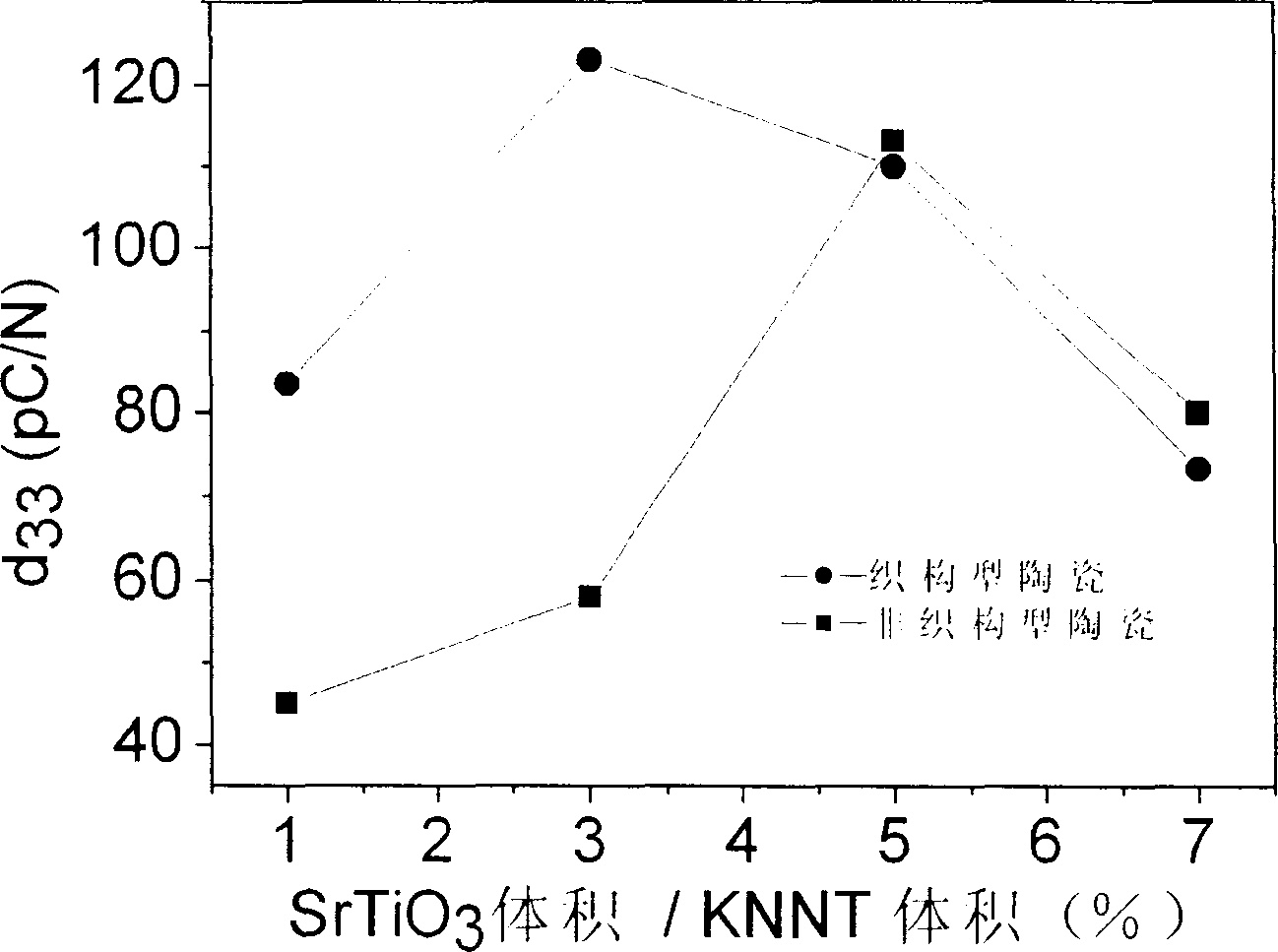

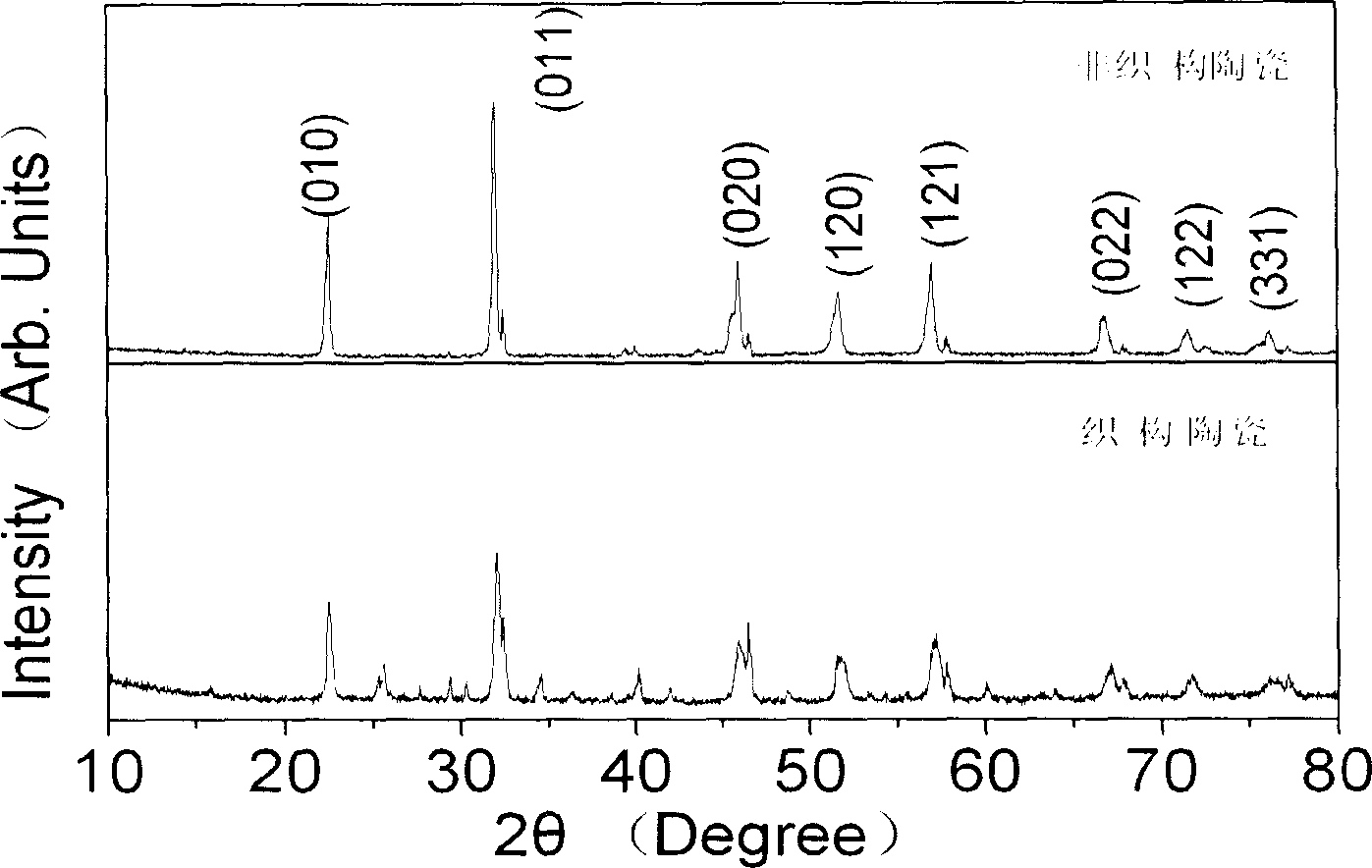

Image

Examples

Embodiment 1

[0029] The synthesis of flake strontium titanate is carried out in two steps:

[0030] The first step is to synthesize the flake precursor Sr by molten salt method in flux 3 Ti 2 o 7 , first press SrCO 3 :TiO 2 = 2.7 ~ 3.5: 2.0 molar ratio weighing, grinding and mixing in ethanol solution for ≥ 8 hours, then adding the flux KCl or the mixture of NaCl and KCl to the slurry according to 35 ~ 65wt% of the dry material, mixing and drying , heat the obtained powder at 1300°C for ≥ 2 hours, cool with the furnace, and obtain the precursor powder Sr after washing 3 Ti 2 o 7 ; the second step through SrTiO 3 Growth primitives in flaky crystal Sr 3 Ti 2 o 7 Superposition on the interface, the precursor Sr obtained in the first step 3 Ti 2 o 7 with TiO 2 Mix in ethanol liquid at a molar ratio of 1:0.7~1.5, stir gently for 30 minutes, add flux KCl or a mixture of NaCl and KCl to the slurry according to 35~65wt% of dry material, and dry the powder at 1150 ~1250℃ heat preserv...

Embodiment 2

[0032] By KNNT and SrTiO 3 The volume ratio is 1:0.01 to prepare lead-free piezoelectric ceramics. The mixed solvent that adopts dehydrated alcohol and butanone volume ratio is 2: 1 composition, and the volume ratio of solvent and mixed powder is 1: 1, and the mixing amount of dispersant, binding agent and plasticizer is respectively the total amount of mixed powder. 1.04wt%, 2.22wt%, 3.86wt%, cold isostatic pressing pressure 400MPa, hot pressing temperature 1000°C, time 1 hour; sintering temperature 1170°C in air atmosphere, sintering time 3 hours.

Embodiment 3

[0034] By KNNT and SrTiO 3 The volume ratio is 1:0.03 to prepare lead-free piezoelectric ceramics. The mixed solvent that adopts dehydrated alcohol and methyl ethyl ketone volume ratio to be 2: 1 composition, the volume ratio of solvent and mixed powder is 2: 1, and the mixing amount of dispersant, binding agent and plasticizer is respectively the total amount of mixed powder. The amount is 1.04wt%, 2.25wt%, 3.96wt%, the cold isostatic pressing pressure is 400MPa, the hot pressing treatment temperature is 1100°C, and the time is 0.5 hours; the sintering temperature is 1180°C in air atmosphere, and the sintering time is 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com